Snakelike optical cable

An optical cable and serpentine technology, which is applied in the field of serpentine optical cables, can solve the problems of easy breakage of optical fibers and cables, which have not been well solved, and achieve the effect of novel overall structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

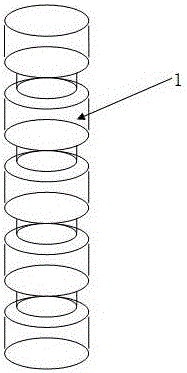

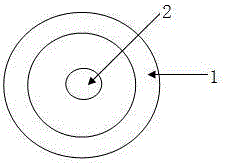

[0013] Example 1 : as shown 1- picture 3 , a serpentine optical cable comprising an outer sheath 1 , the outer sheath is equipped with a multi-core sub-unit 2 , the outer sheath 1 Set as PPT Serpentine tube sheath, the optical cable is a serpentine optical cable, using bend-insensitive optical fiber, to ensure that the additional attenuation is small enough when used in bending situations. The outer sheath is configured as a cavity structure, which is convenient for the subunit to move in the cavity.

Embodiment 2

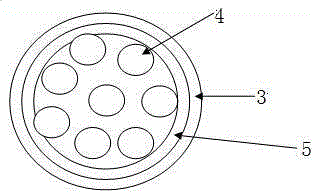

[0014] Example 2 : as shown 1- picture 3 , as an improvement of the present invention, the multi-core sub-units sequentially include sheath layers from outside to inside 3 , Aramid layer 5 and colored fiber optics set inside 4 , the outer sheath is set as a cavity structure, the sheath layer 3 It is a cylindrical structure, and the number of colored fibers is 2-12 core. The sub-unit adopts a low-friction sheath and cooperates with the structure of the cavity to ensure that the sub-unit has enough room for movement in the cavity and will not be excessively bent when the optical cable is bent; PPT The serpentine tube sheath ensures that the optical cable will not continue to bend after bending to the designed minimum bending radius, so as to achieve super bending resistance.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap