Microscope Auxiliary Device to Eliminate Blind Spots on the Surface of the Object to Be Tested

An auxiliary device and object surface technology, applied in microscopes, instruments, optics, etc., can solve the problems of damaging the original structure of the microscope, expensive microscopes, and reduced imaging quality, and achieve the effects of simple installation, stable structure, and increased information volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

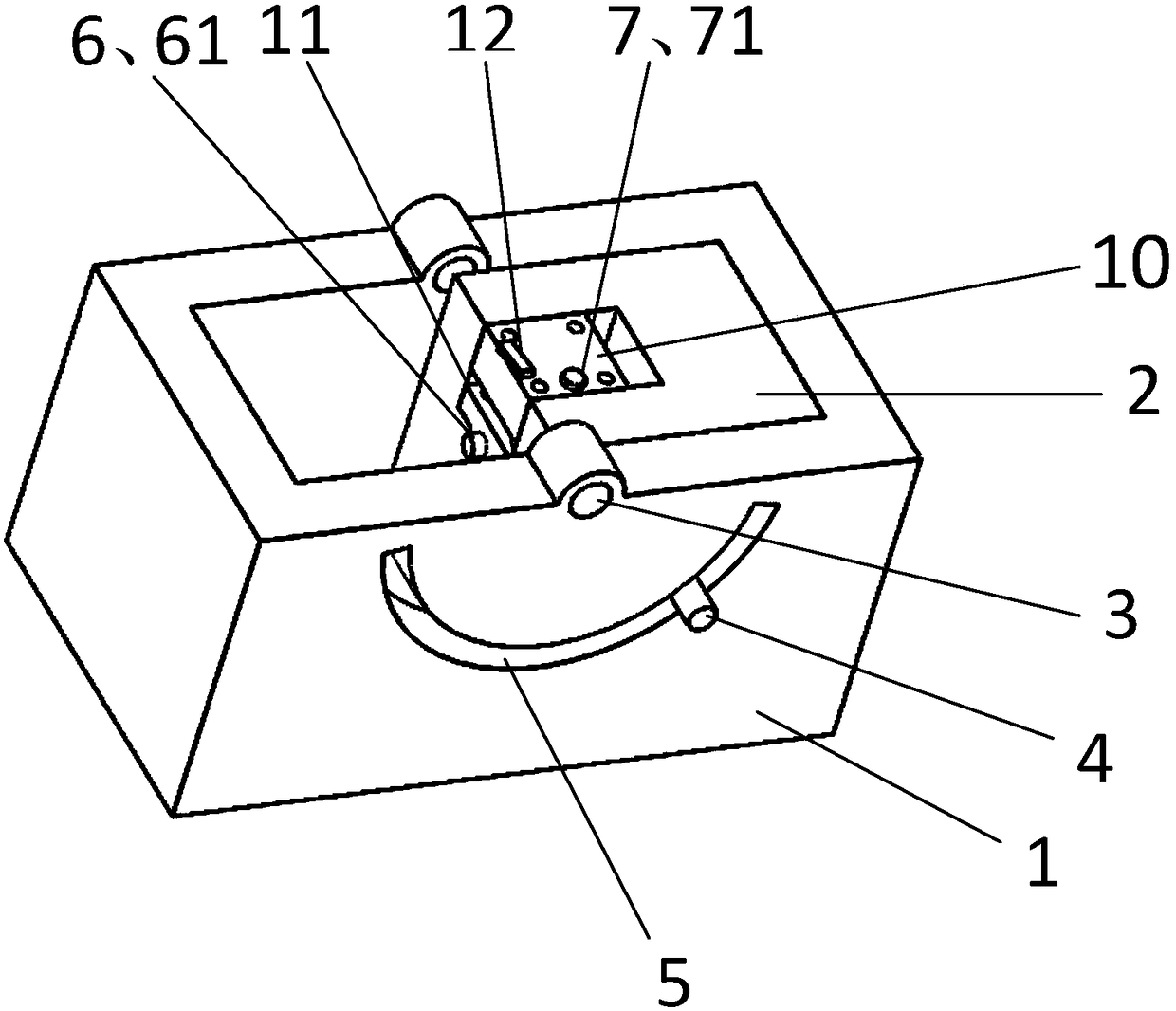

[0026] Such as Figure 2-Figure 6 As shown, the upper surface of the base is provided with a groove and a rotating shaft crossing the groove, and one corner of the rotating base is installed in the groove through the rotating shaft, and the rotating base can be freely rotated relative to the groove by driving the rocker; The base body is provided with a gap at the position where the rotating shaft is located, and a shelf bracket is fixedly arranged on the concave surface formed by the gap, and the shelf and the shelf bracket are kept at a distance from the inner elevation of the concave surface formed by the gap; The component and the vertical adjustment component are installed and connected with the shelf bracket.

[0027] The horizontal adjustment assembly specifically includes an adjustment screw that runs through the shelf support horizontally from the outside of the gap to the inside of the gap, and a spring that is horizontally sleeved on the adjustment screw near the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com