All-round visual pool boiling experimental device

An experimental device and all-round technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of limited observation effect, difficult visualization, and inability to observe the bottom surface of bubbles, and achieve the effect of simple and compact structure and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

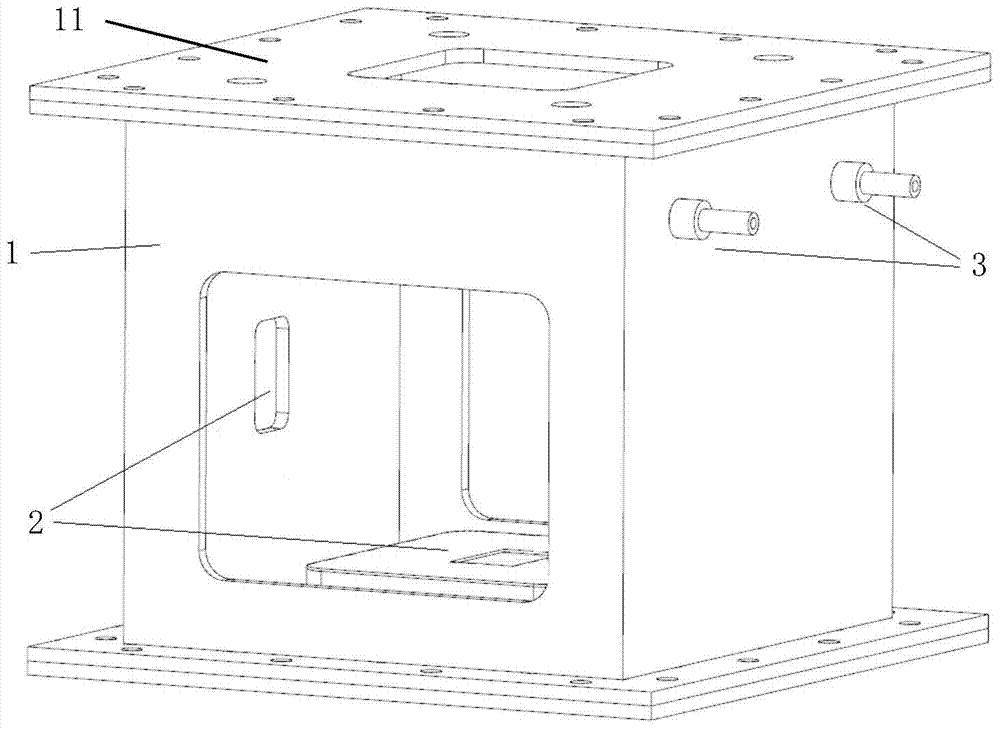

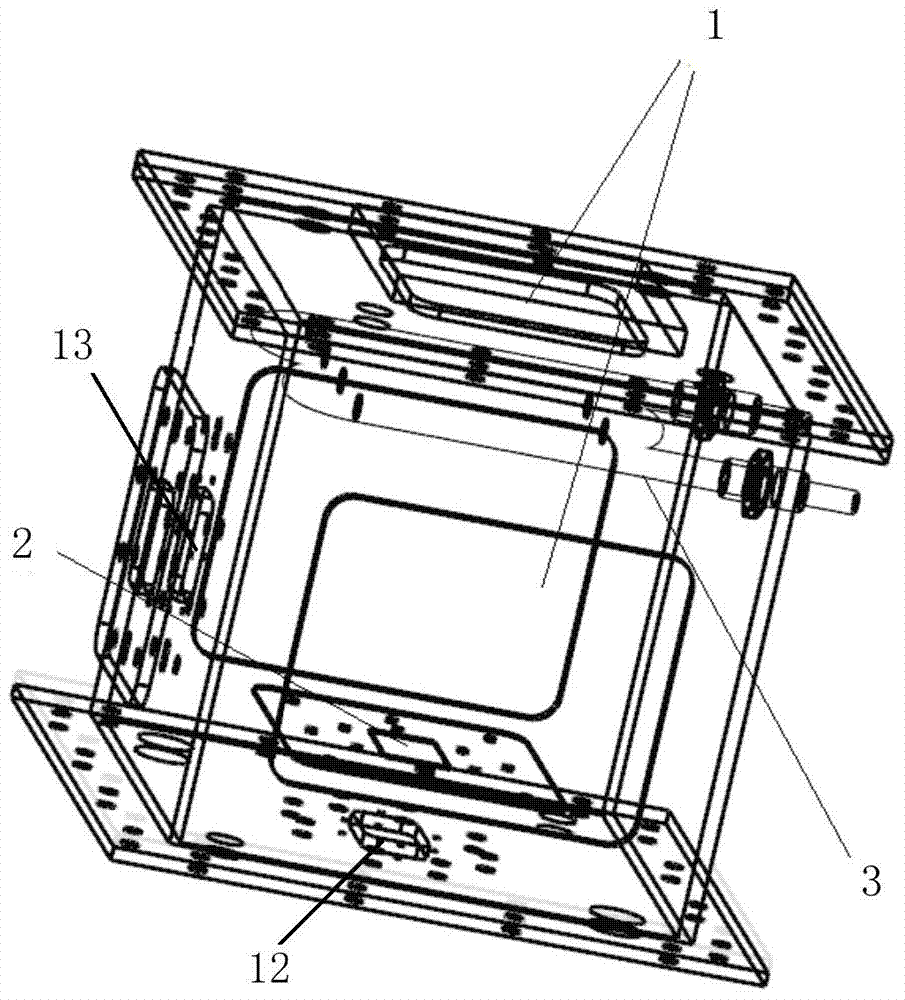

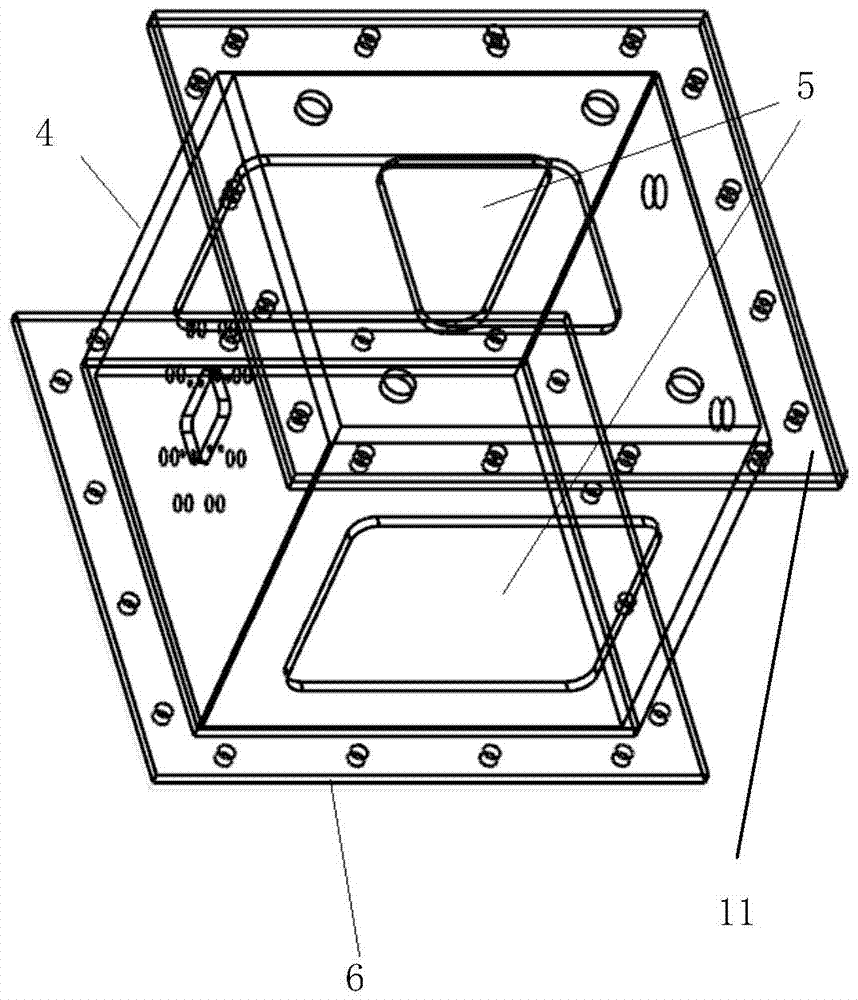

[0015] Implementation Case 1: Combining Figure 1 to Figure 5 , the present invention includes an observation container 1, a heating assembly 2 and a condensation assembly 3, the heating assembly 2 includes a fixed bracket 8 and an ITO heating glass 7 installed on the fixing bracket 8, the ITO heating glass 7 can realize and maintain the studied working medium The boiling state, and the fixed bracket 8 fixes the ITO heating glass 7, which contains wires, and the wires are connected to the external circuit to provide heating electricity for the ITO heating glass 7. Using the ITO heating glass 7 as a heating element can maximize the heating of the wall surface. The boiling phenomenon can be studied visually to realize direct research on the bubble growth process, and observation can be performed on the back of the bubble; the observation container 1 includes a container body 4 and an observation window 5, and the container body 4 includes four sides and a container bottom plate 6...

Embodiment example 2

[0018] Implementation Case 2: According to the all-round visual pool-type boiling experimental device described in Embodiment Case 1, a second ITO heating glass installation hole 13 is provided on the side of the container body 4, and the second heating assembly is installed through the ITO heating glass installation hole 13 On the container body 4 sides. That is to say, the present invention is respectively provided with heating components 2 on the bottom surface and the side surface of the observation container 1, which can complete the different effects on the bubbles produced by the different positions of the heating surface, that is, can study the generation process of the bubbles at different heating positions, and realize the different heating components. A study of the effect of location on pool boiling.

Embodiment example 3

[0019] Example 3: According to the all-round visual pool boiling experimental device described in Example 1 and Example 2, a container cover 11 is provided on the upper part of the container body 4 , and an observation window 5 is provided on the container cover 11 . In this way, not only can the research on the pool boiling of ordinary liquids be realized, but for some volatile heating working fluids, if there is no container cover 5, the working fluid will gradually decrease as the heating progresses, which will affect the experiment, so the container cover is provided After 5, this effect can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com