Method for detecting mechanical properties of rotor pigeon tail part of pumped storage power generation motor

A technology for generating electric motors and pumped storage, which is applied in the fields of electrical digital data processing, computer-aided design, and special data processing applications. Time-varying situations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

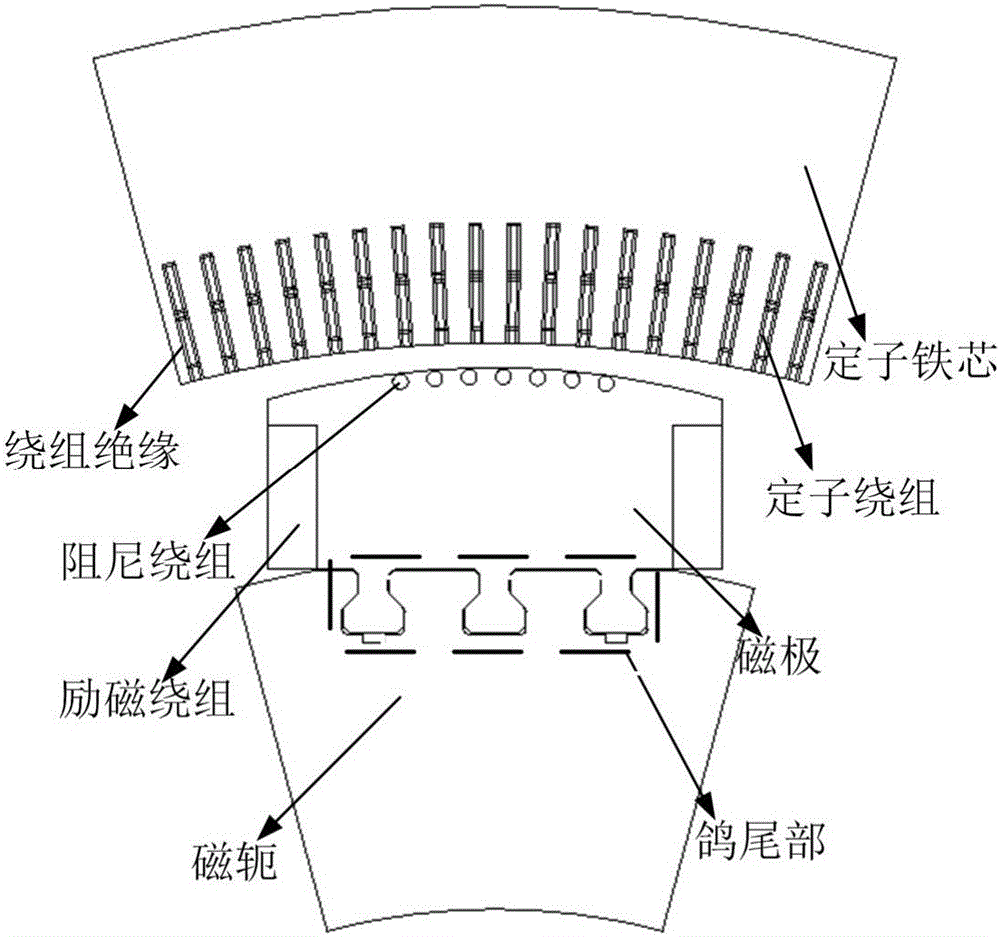

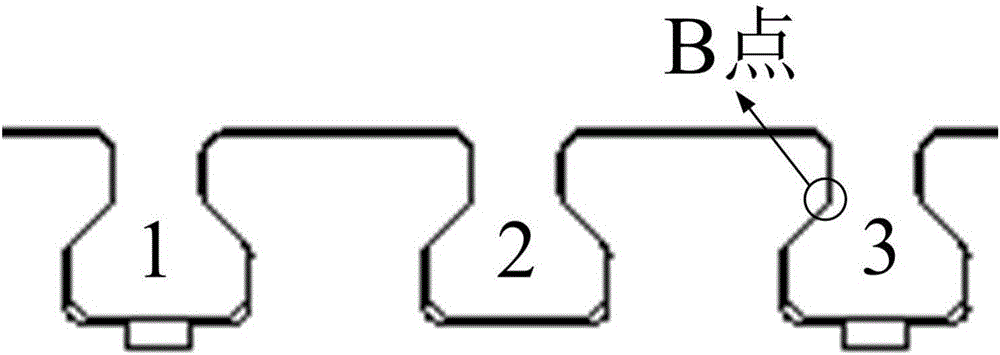

[0060] A method for detecting the mechanical performance of the rotor pigeon tail of a pumped storage generator motor, comprising the following steps:

[0061] 1) According to the rotor speed curve under the actual operating conditions provided by the pumped storage power plant, the acceleration distribution is obtained as the load. Through dynamic calculation, the dove tail of the rotor of the generator motor is obtained in the power generation start-up condition, power generation shutdown condition, and electric start-up condition respectively. The distribution of the stress caused by the centrifugal force over time under the conditions of electric shutdown, load shedding and runaway conditions;

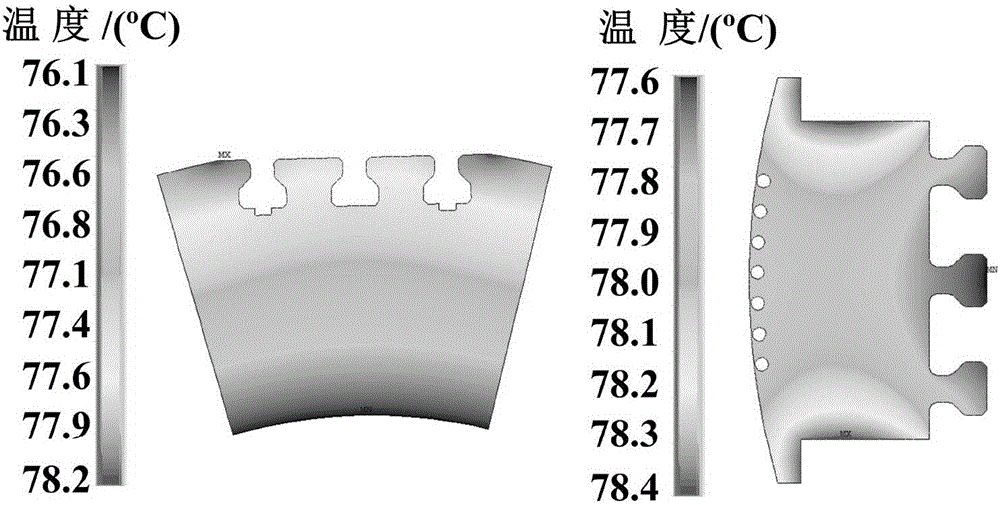

[0062] 2) The temperature change of the motor caused by electromagnetic loss, and the resulting thermal stress and the stress caused by centrifugal force are vector summed;

[0063] 3) According to the total stress distribution under the power generation start-up conditions, power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com