Power supply interface assembly

A technology for power supply interfaces and components, which is applied to electrical components, parts and circuits of connecting devices, etc., and can solve the problems of inability to guarantee the reliability and stability of electrical bonding, inability to guarantee, and inability to realize automatic implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

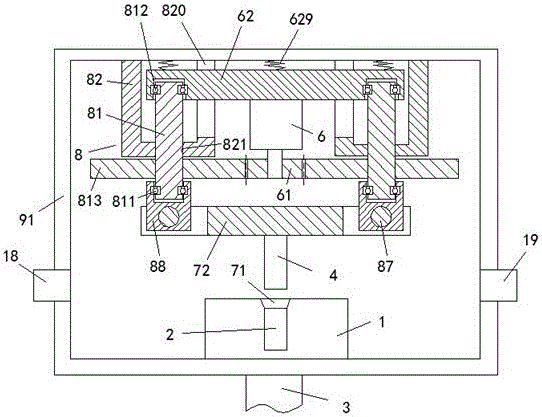

[0007] Combine below figure 1 The present invention will be described in detail.

[0008] A power supply interface assembly according to an embodiment includes a housing 91, a power supply socket device 1 disposed on the lower side wall of the housing 91, and a socket device 1 disposed on the upper side wall of the housing 91. An electric plug device, the power supply jack device 1 includes a power supply cable 3 and a power supply hole 2 for electrically connecting with the electric plug device, and the electric plug device includes a socket fixed to the upper side wall of the housing 91 Two jacking screw assemblies 8 are connected, and the two jacking screw assemblies 8 are arranged symmetrically with respect to the longitudinal axis of the housing 91 and each includes: a screw thread fixed on the upper side wall of the housing 91 The fixing sleeve 82, the pressing screw rod 81 threadedly engaged with the threaded hole 821 in the lower end wall of the threaded fixing sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com