Rotor guide bar tensioning tool and tensioning method of AC traction motor

A traction motor and tensioning technology, used in electromechanical devices, manufacturing squirrel cage rotors, manufacturing motor generators, etc., can solve problems such as prevention, frequent failures, scratching of stator coils, etc., to relieve maintenance pressure and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

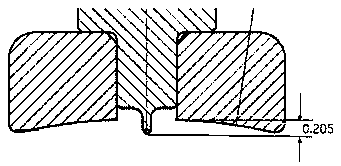

[0020] In order to ensure the quality of the rotor after replacing the squirrel cage, reduce the movement of the guide bars in the notch of the silicon steel sheet, and prevent the phenomenon of bar de-soldering in the rotors that have not yet had de-soldering of the guide bars, it is necessary All the guide bars of the rotor are newly expanded and tightened, and all the guide bars of the rotor after replacing the new squirrel cage are expanded and tightened to eliminate the phenomenon that the guide bars are lifted or broken, thereby improving the life of the rotor.

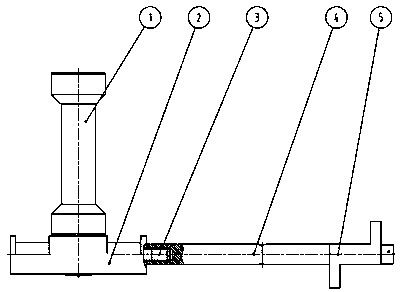

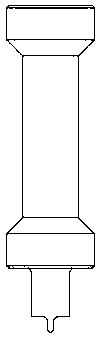

[0021] Such as figure 1 and figure 2 As shown, it is the tightening tool for the rotor guide bar of the AC traction motor, including the punch 1, the punch guide seat 2, the stud bolt 3, the coupling rod 4 and the positioning block 5, the punch 1 is placed on the punch guide seat 2, and the punch The front end of the head guide seat 2 is connected to the connecting rod 4 by a stud bolt 3 , and a positioning bl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap