Blind rivet arrangement and joint

A blind rivet, rivet head technology, applied in the direction of rivets, screws, connecting components, etc., can solve problems such as rotational symmetry deviation, and achieve the effect of achieving retention force, realizing cost saving, good centering or guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

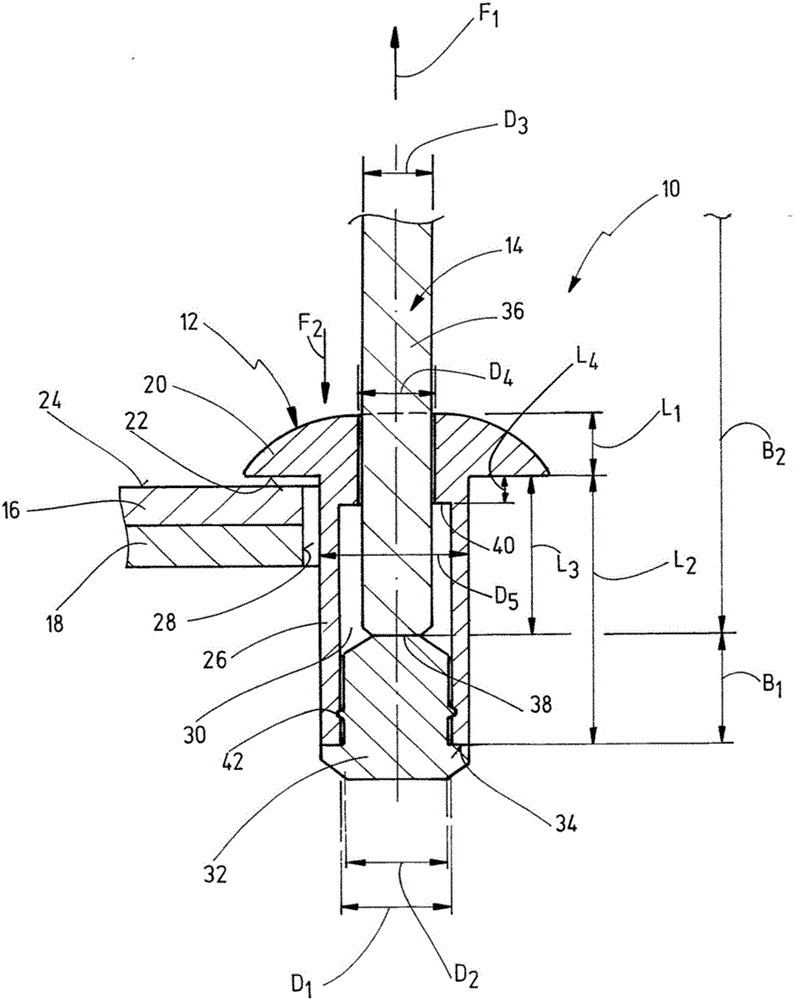

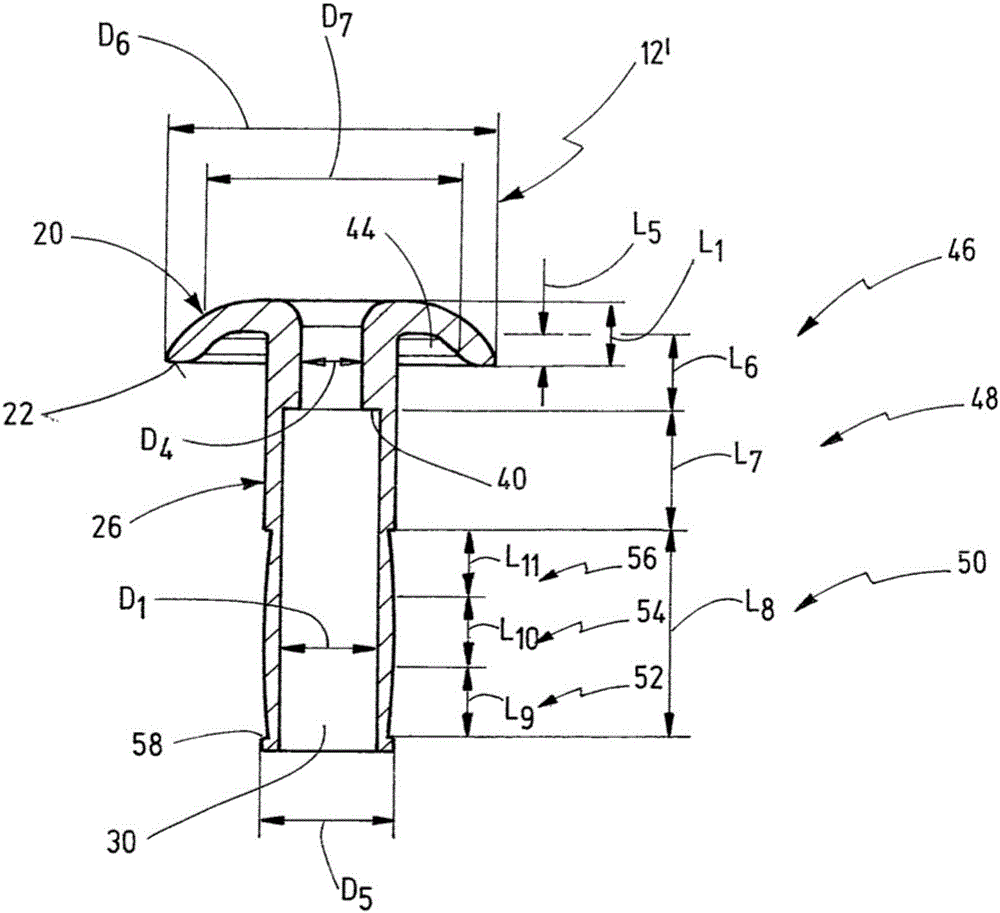

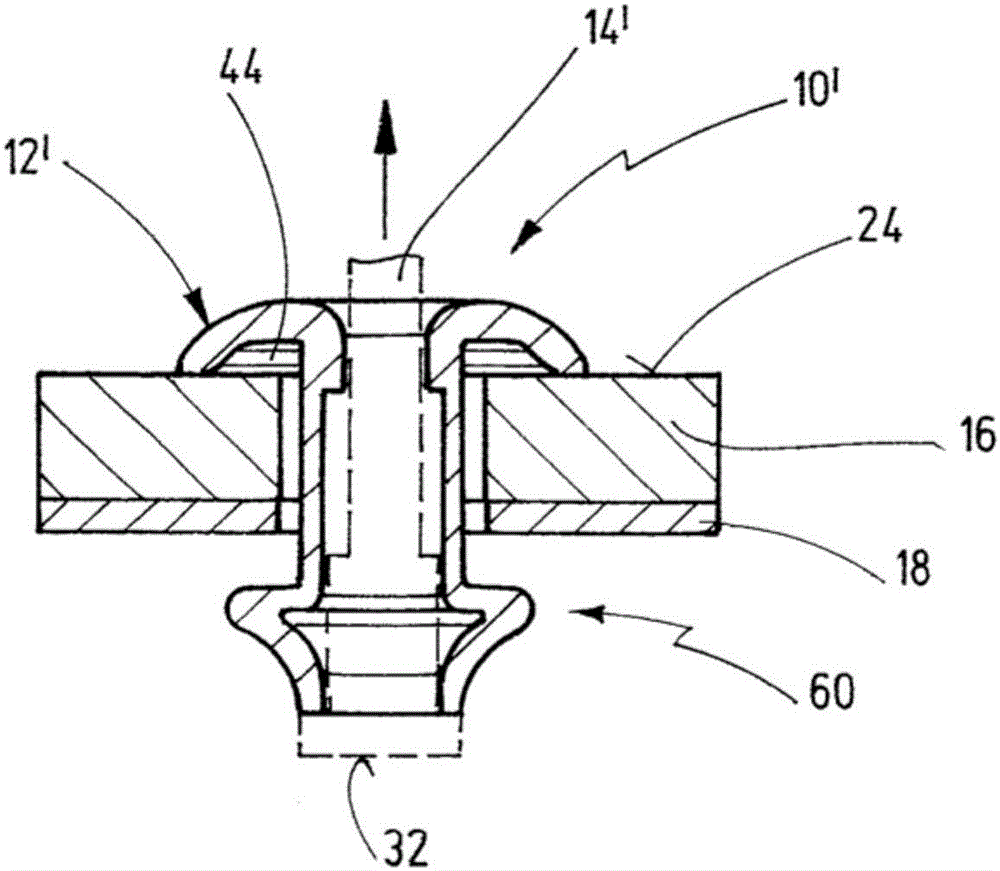

[0059] figure 1 A schematic view in longitudinal section of a first embodiment of a blind rivet arrangement according to the invention is shown, generally designated by the reference numeral 10 .

[0060] The blind rivet set 10 includes a rivet body 12 and a rivet mandrel 14 . The blind rivet arrangement 10 may be used to join a workpiece arrangement comprising at least one first workpiece 16 (visible side workpiece) and one second workpiece 18 (blind side workpiece).

[0061] The rivet body 12 comprises a rivet head 20 in known manner comprising a contact face 22 to abut against a top surface 24 of the visible side workpiece 16 . The rivet head 20 is joined to a rivet shank 26 which may be inserted into a workpiece hole 28 in the workpiece arrangement. The rivet body 12 is penetrated by an axially continuous rivet hole 30 .

[0062] The mandrel 14 includes a mandrel head 32 realized for abutting against an end surface 34 of the rivet shank 26 . Furthermore, the mandrel 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com