Blade tip clearance calibration system and calibration method based on AC discharge

A technology of blade tip clearance and AC discharge, applied in the direction of using electrical devices, electromagnetic means, instruments, etc., can solve problems such as affecting flight safety, and achieve the effects of high displacement accuracy, convenient installation and use, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

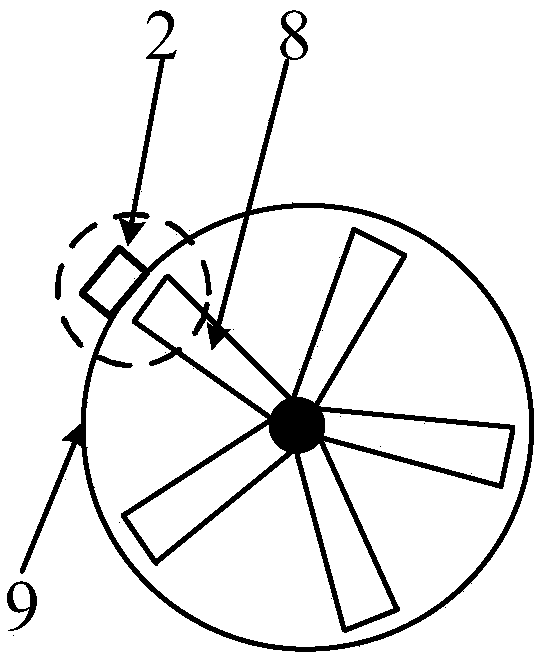

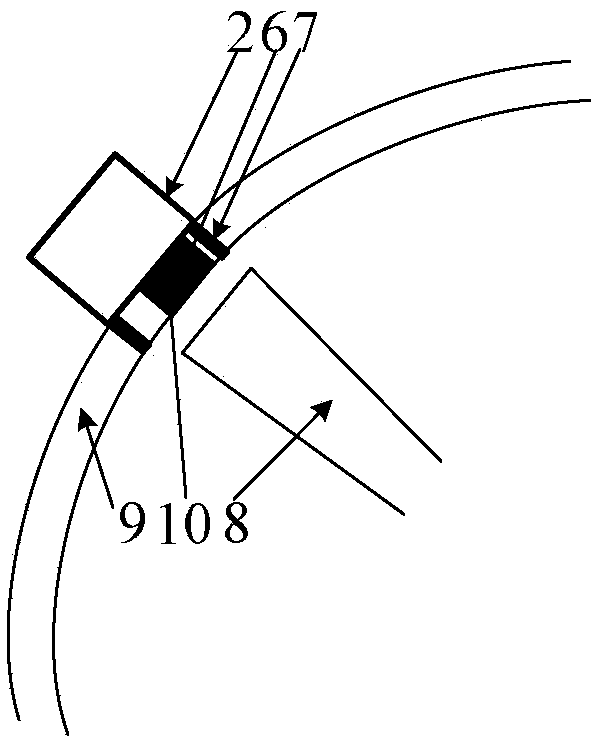

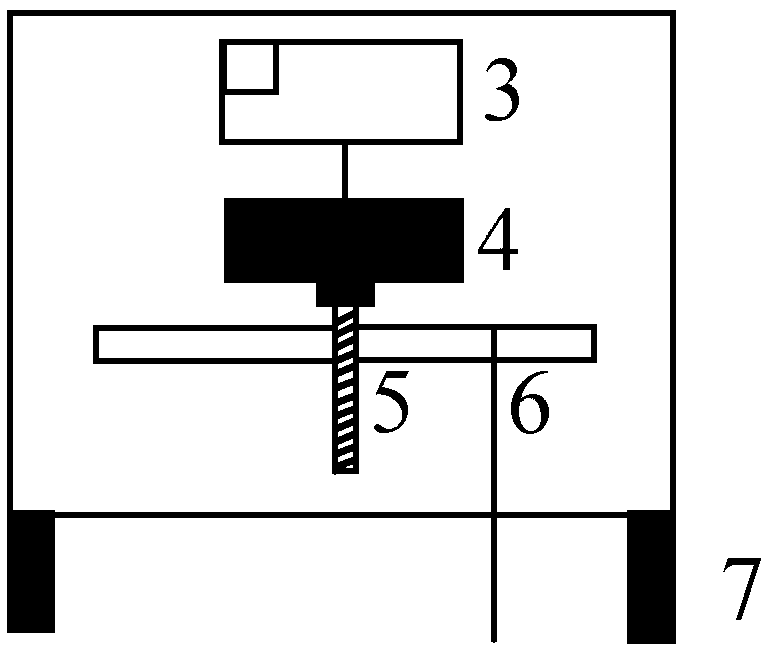

[0023] Such as Figure 4 As shown, the present invention provides a blade tip clearance calibration system based on AC discharge, including a voltage output module 1, a probe 6, an actuator 2, a current measurement conversion module and a central processing control module 14, wherein the actuator 2 includes a step Enter the motor control circuit 3, the stepping motor 4 and the ball screw 5, the stepping motor 4 is connected to the driving end of the ball screw 5, the stepping motor control circuit 3 controls the rotation of the stepping motor 4, thereby pushing the ball screw 5 Move; the tip of the probe 6 is inserted into the casing 9 from the outside of the casing 9, and cooperates with figure 1 and figure 2 As shown, and make the tip of the probe 6 flush with the inner wall of the casing 9, and wrap the insulating layer 10 at the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com