Programmed type shift riveting machine

A riveting machine and program-controlled technology, applied in the field of program-controlled shift riveting machines, can solve the problems of increased labor intensity and increased construction difficulty for operators, and achieve the effects of good quality consistency, controllable displacement, and high riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

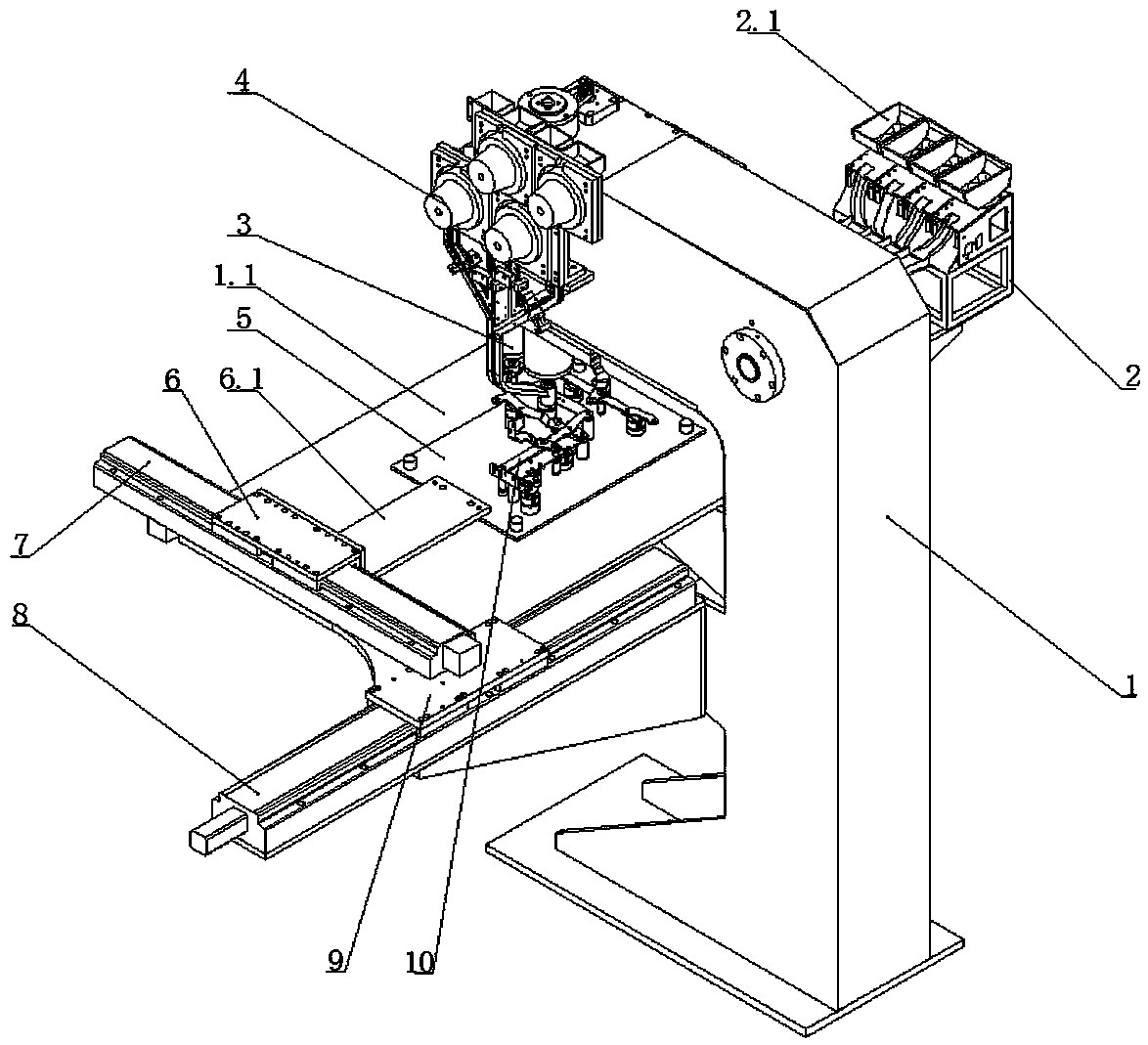

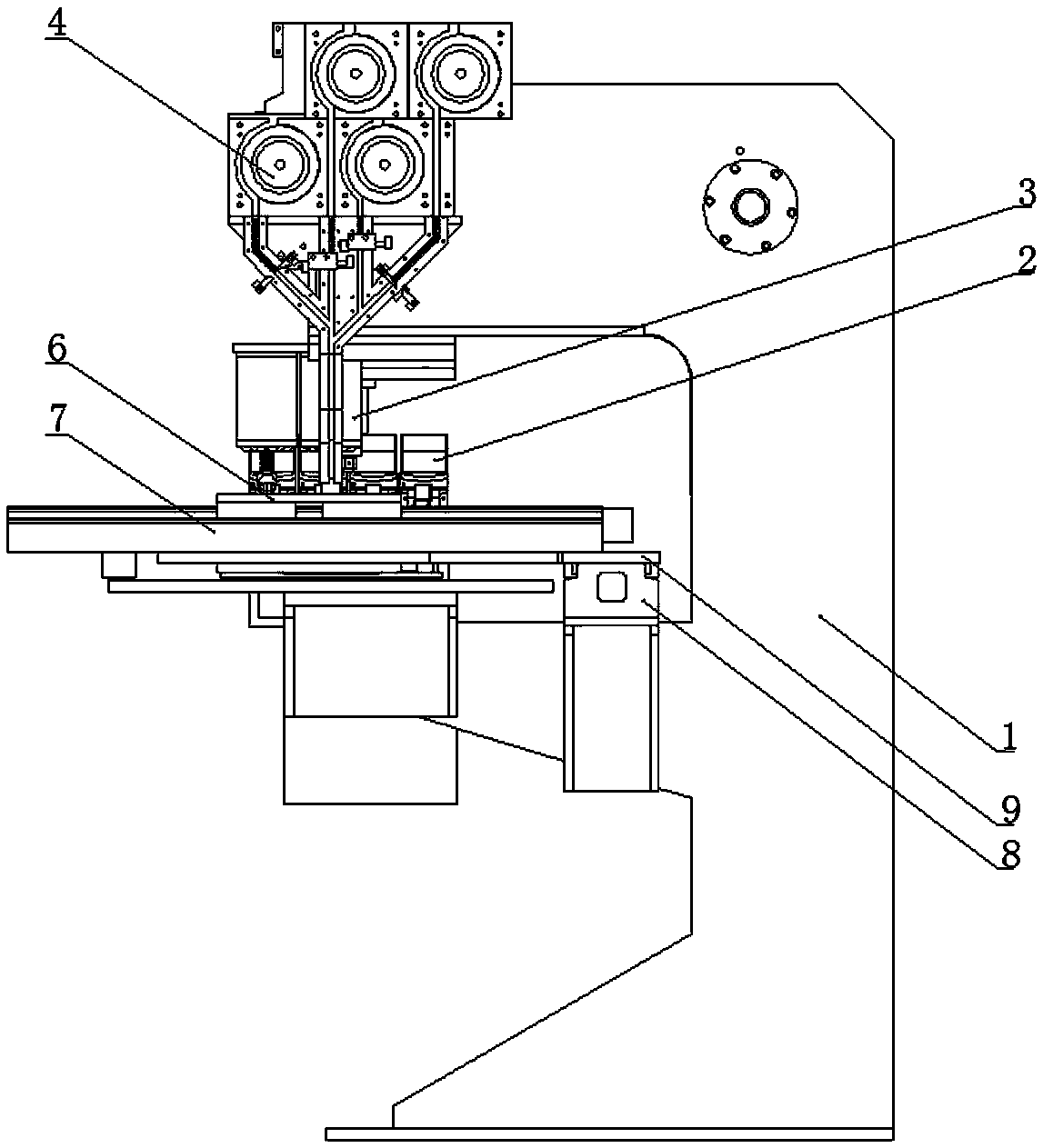

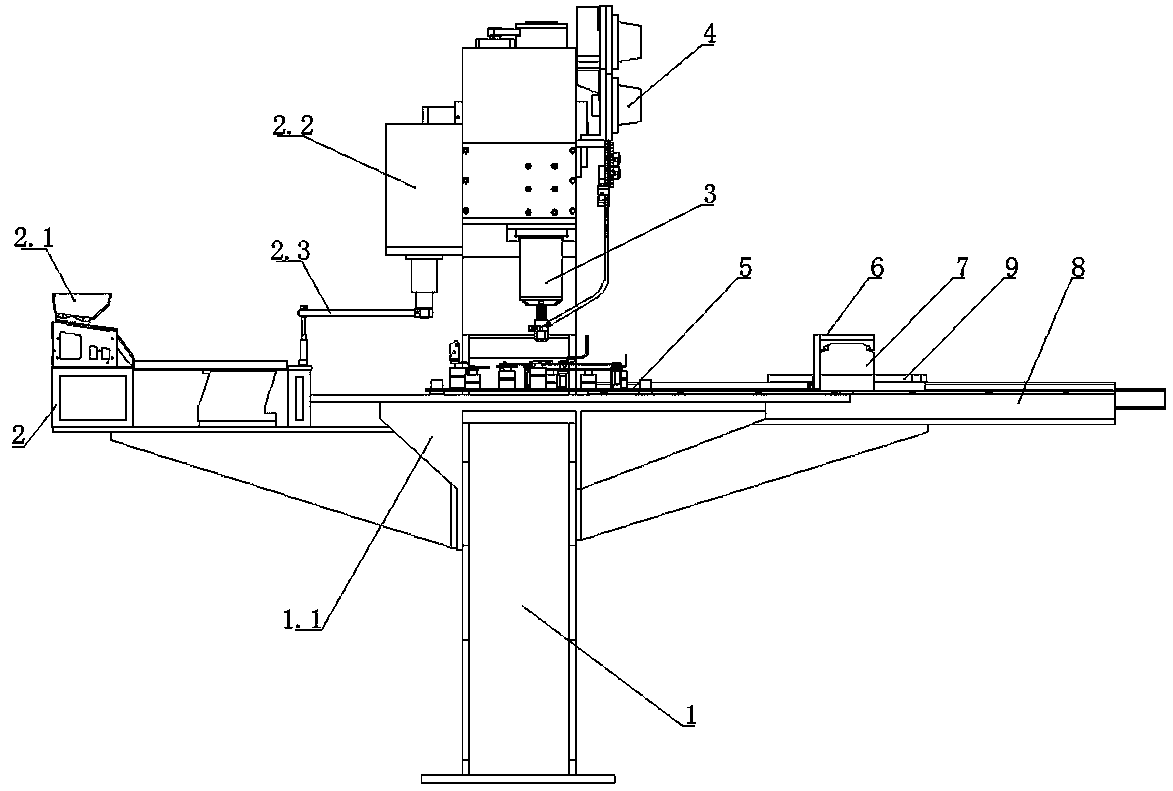

[0018] figure 1 The program-controlled displacement riveting machine shown includes a bed 1, a gasket selection device 2, a punch 3, a controllable rivet distributor 4, a workbench 5, a Y slide 6, a Y guide rail 7, and an X guide rail 8 and X slide 9. The bed 1 is a skeleton member of the riveting machine, and the waist of the vertical bed 1 is provided with a flat base 1.1, and a rectangular workbench 5 is placed on the upper plane of the base 1.1, and the workbench 5 is used for installing workpieces 10 . A punch 3 and a controllable rivet dispenser 4 are installed on the upper end of the bed 1, and the workbench 5 is located under the punch 3. In the present invention, a corner of the base 1.1 of the bed 1 is provided with a straight X guide rail 8 and a Y guide rail 7, and the supporting X slide 9 slides left and right along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com