Jiggle corrosion abrasion-micro amplitude collision abrasion test machine

A fretting corrosion and wear test technology, which is applied in the field of testing machines, can solve the problems affecting the reliability of the blade, the gap becomes larger, and the "tightness" becomes smaller, so as to reduce the friction, improve the utilization rate, and reduce the force. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

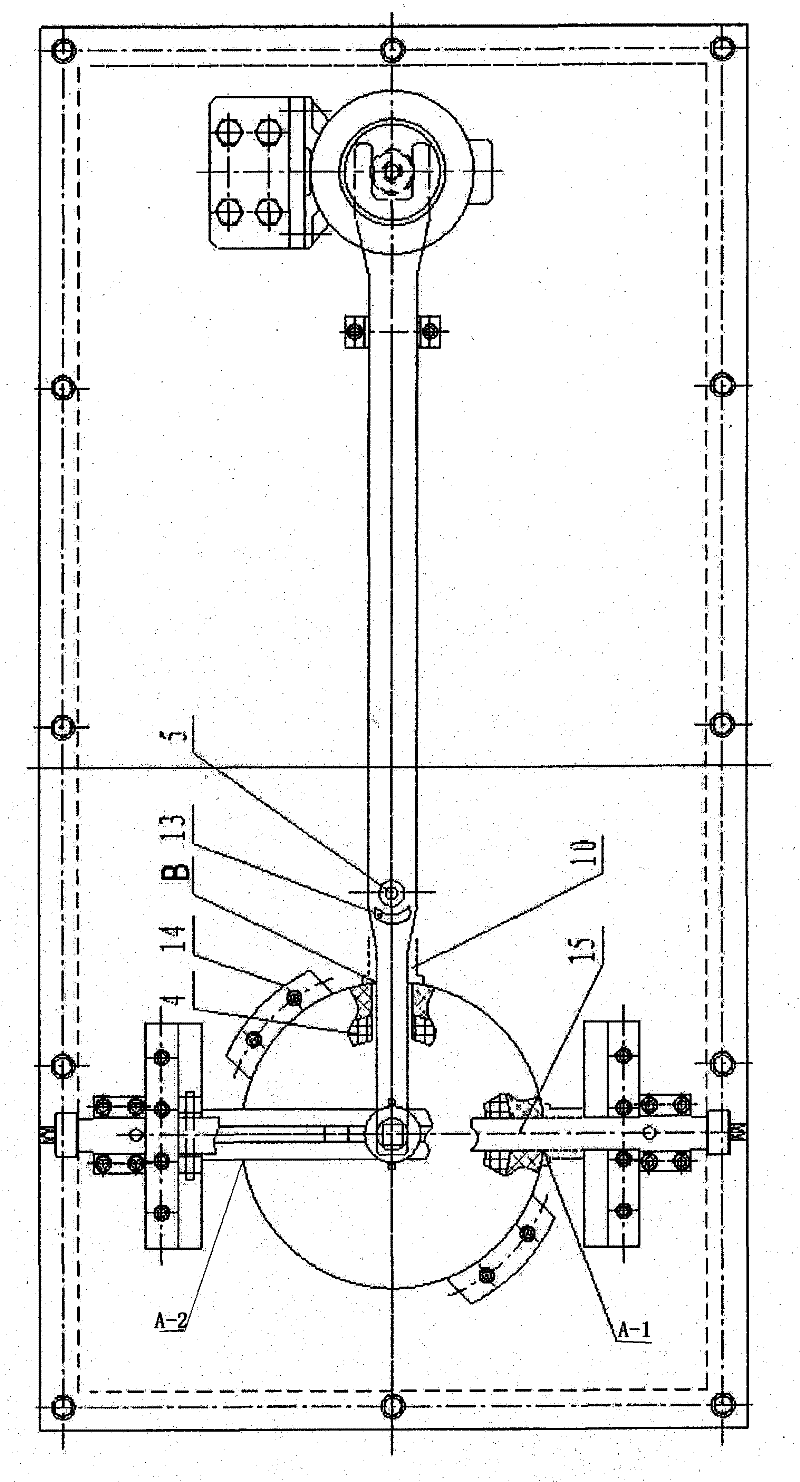

[0051] The present invention is described in more detail below in conjunction with accompanying drawing example:

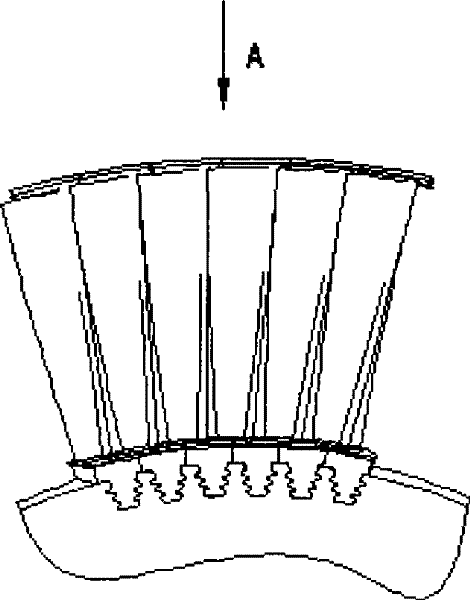

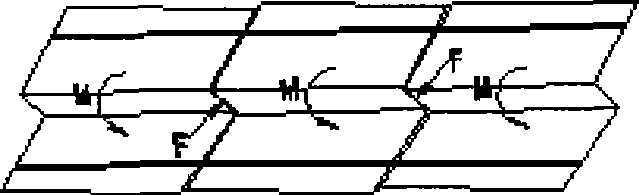

[0052] combine figure 1 , relying on collision limiting and damping to control the dynamic stress of the turbine shrouded blade and other blade devices under the working state of the blade, its typical physical model is as follows figure 1 . Mi represents the mass of each impacting and impacted object, Ke and Ce represent the system stiffness and damping respectively, δ is the gap between the two objects, and F(t) is the external force acting on the impacting object. In this test device, the test pieces on the left and right sides of the test section and the elastic collision devices with controllable stiffness on both sides of the heating furnace are the concrete embodiment of this model.

[0053] Relying on the pre-twist of the blade and the elastic torsion under the working condition, the "tightness" between the damping surfaces of the shroud is generated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com