A single-side clamping straightening device and straightening method for material rods

A technology of straightening device and material bar, applied in feeding device, positioning device, storage device, etc., can solve the problems of unsatisfactory straightening effect, insignificant yield platform, distortion of yield strength, etc., so as to protect the overall performance and damage Small, reducing the effect of cold work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

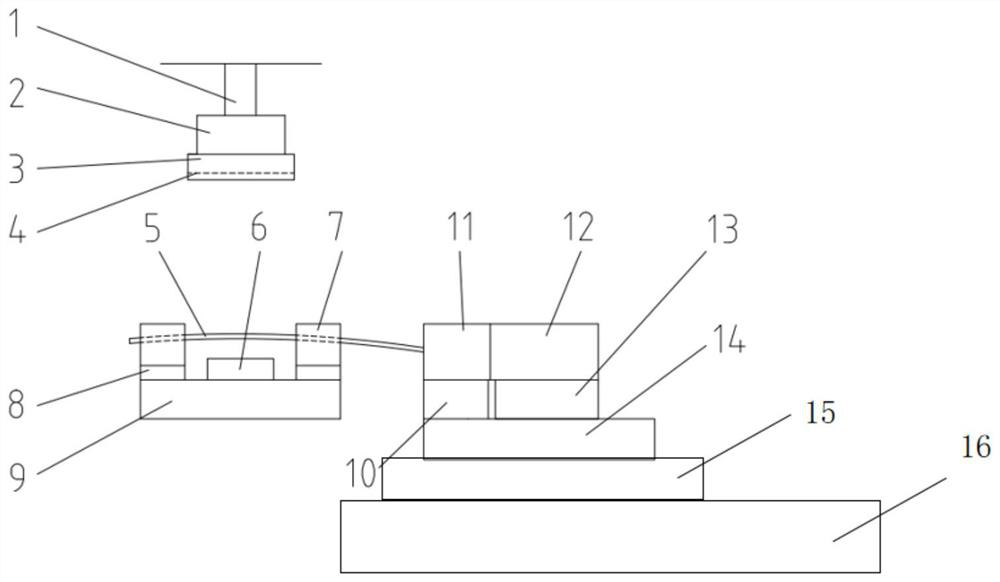

[0042] The present application proposes a one-side clamping type straightening device for the material rod, which is used for straightening without cold hardening after one-side clamping of the material rod during the straightening of the material rod.

[0043] In order to facilitate the understanding of the working principle and usage of the one-side clamping type straightening device for the material rod, the structure of the one-side clamping type straightening device for the material rod is given below, and the single-side clamping of the material rod in this application is based on its development Description of the type straightening device.

[0044] Refer to the structure of the single-side clamping type straightening device for the rod figure 1 shown.

[0045] A single-side clamping type straightening device for material rods, comprising:

[0046] The hydraulic / pneumatic cylinder driving device includes a hydraulic cylinder / pneumatic cylinder 1 and a cylinder connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com