Automatic conveying device capable of adjusting width at equal intervals and used for materials

A technology of automatic conveying device and equidistant spacing, applied in conveyor control device, conveyor, transportation and packaging, etc., can solve problems such as poor reliability and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

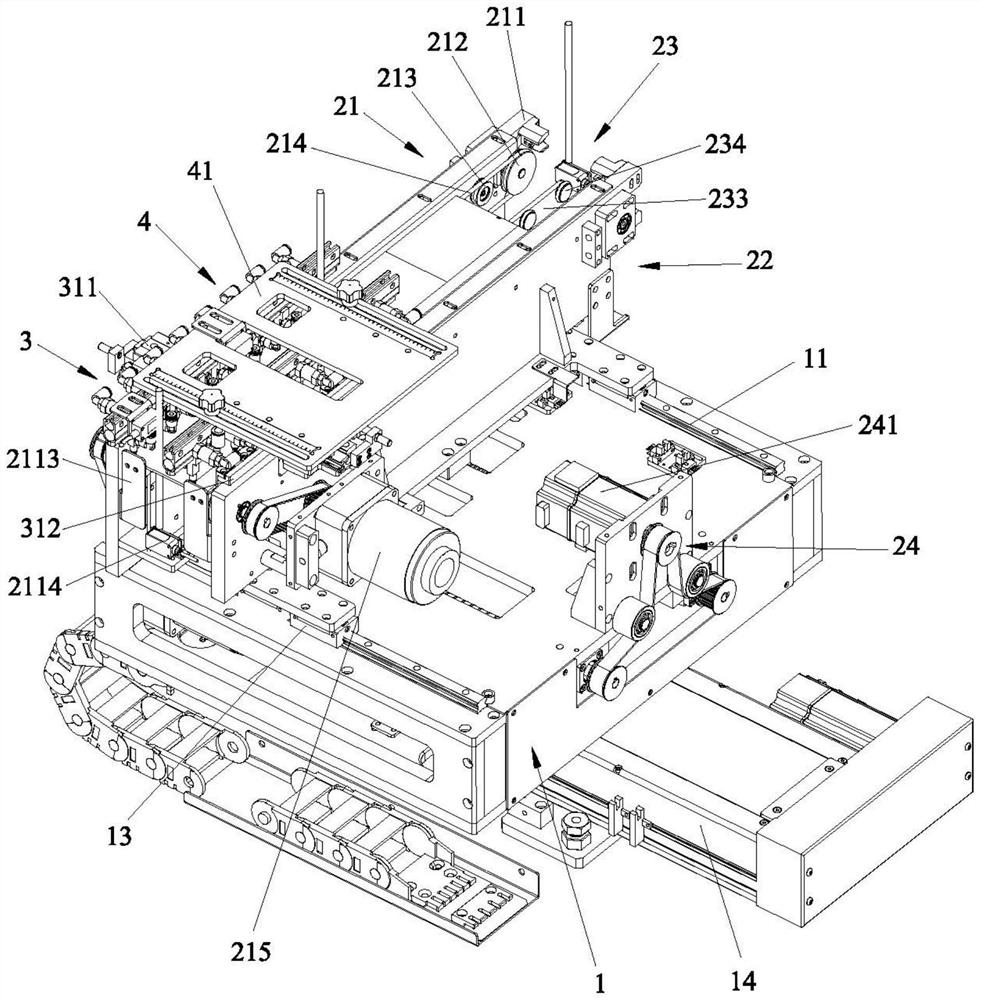

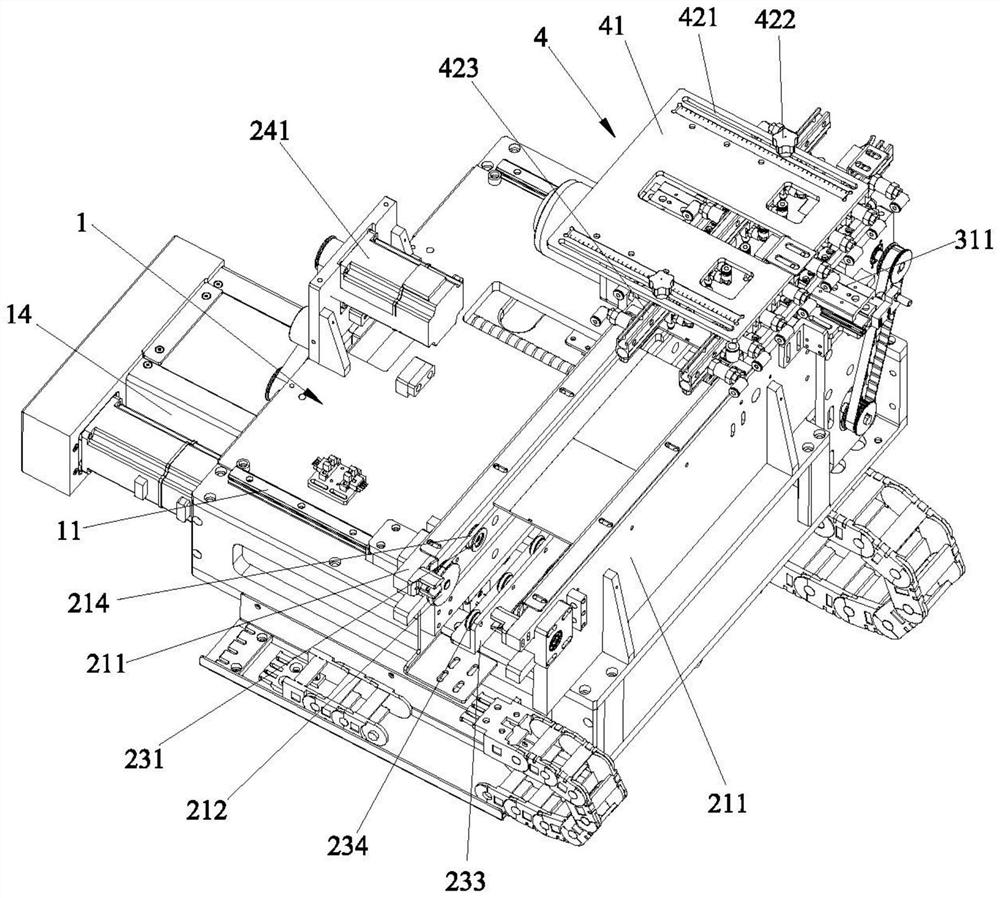

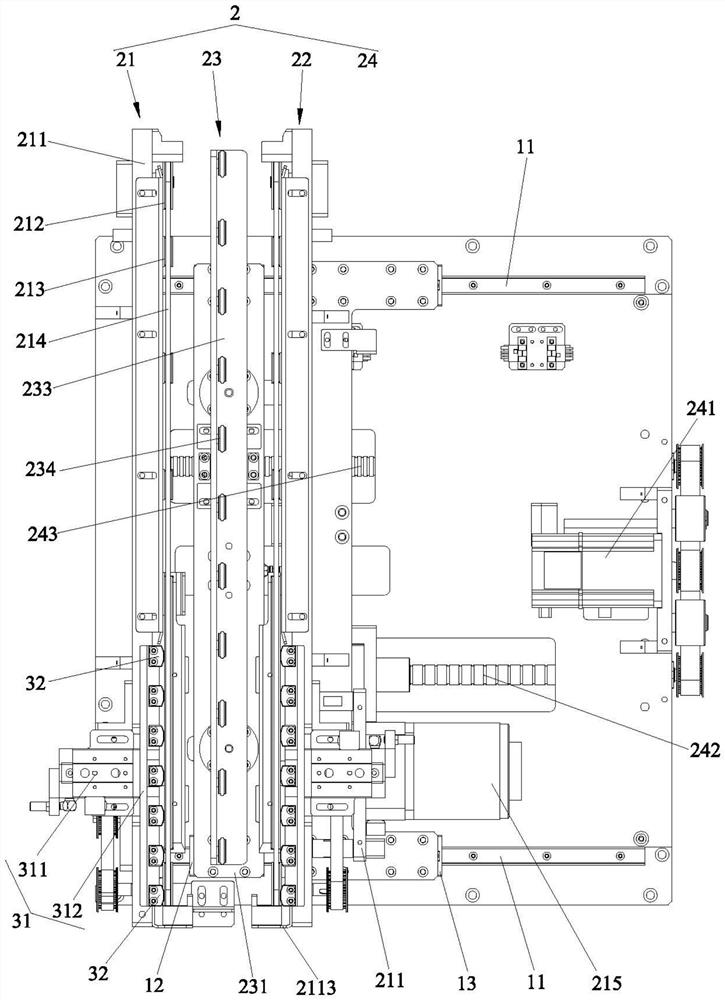

[0039] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of a preferred embodiment of the present invention, which is an automatic conveying device for equal-spacing width adjustment of materials, including a base 1 , a conveying mechanism 2 and a flapping mechanism 3 .

[0040] Please refer to Figure 1 to Figure 4As shown, the conveying mechanism 2 includes a first conveying module 21 fixedly installed on the base 1 , a second conveying module 22 movably installed on the base 1 , a first supporting module 23 movably installed on the base 1 , and The first width adjustment module 24 for driving the displacement of the second conveying module 22 and the first supporting module 23; Between a conveying module 21 and a second conveying module 22 ; when the first width adjusting module 24 drives the second conveying module position 22 to move, it simultaneously drives the first supporting module 23 to displace and is located in the first conveying mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com