bracket for friction element of double clutch

A friction element and dual clutch technology, which is applied in the field of brackets, can solve the problems of time-consuming joining process, reducing the lasting strength of brackets, expensive bracket manufacturing, etc., and achieve cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

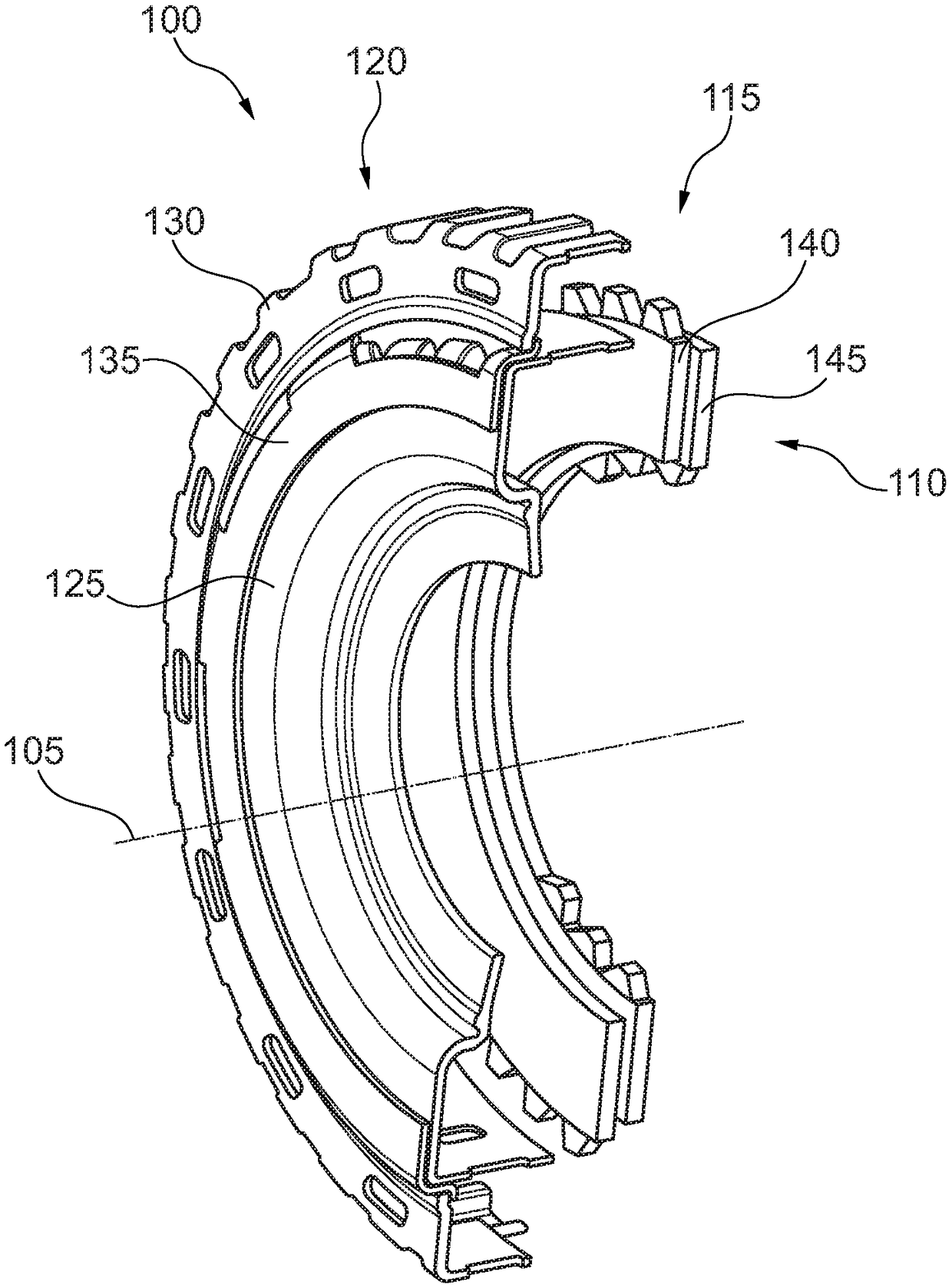

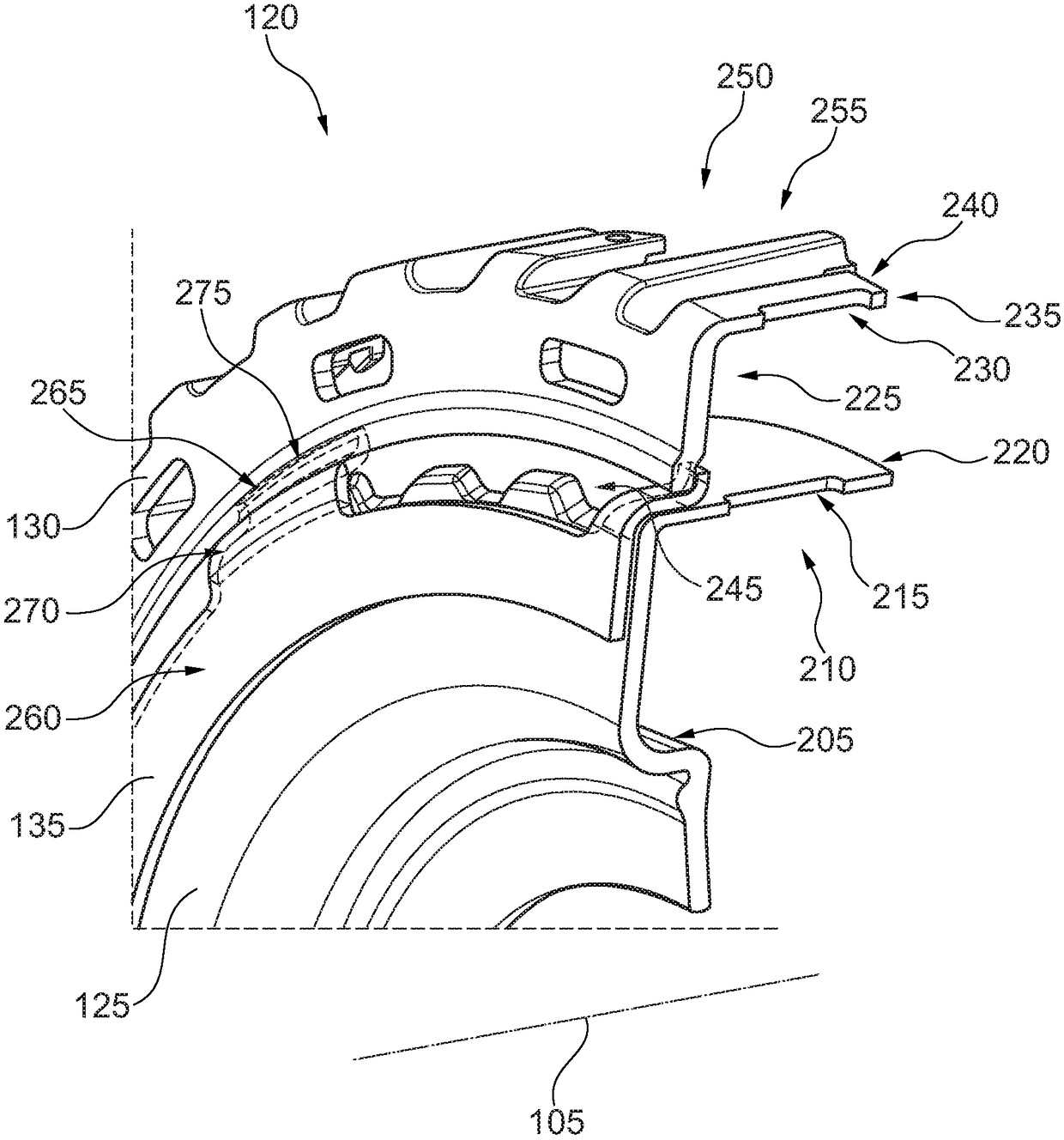

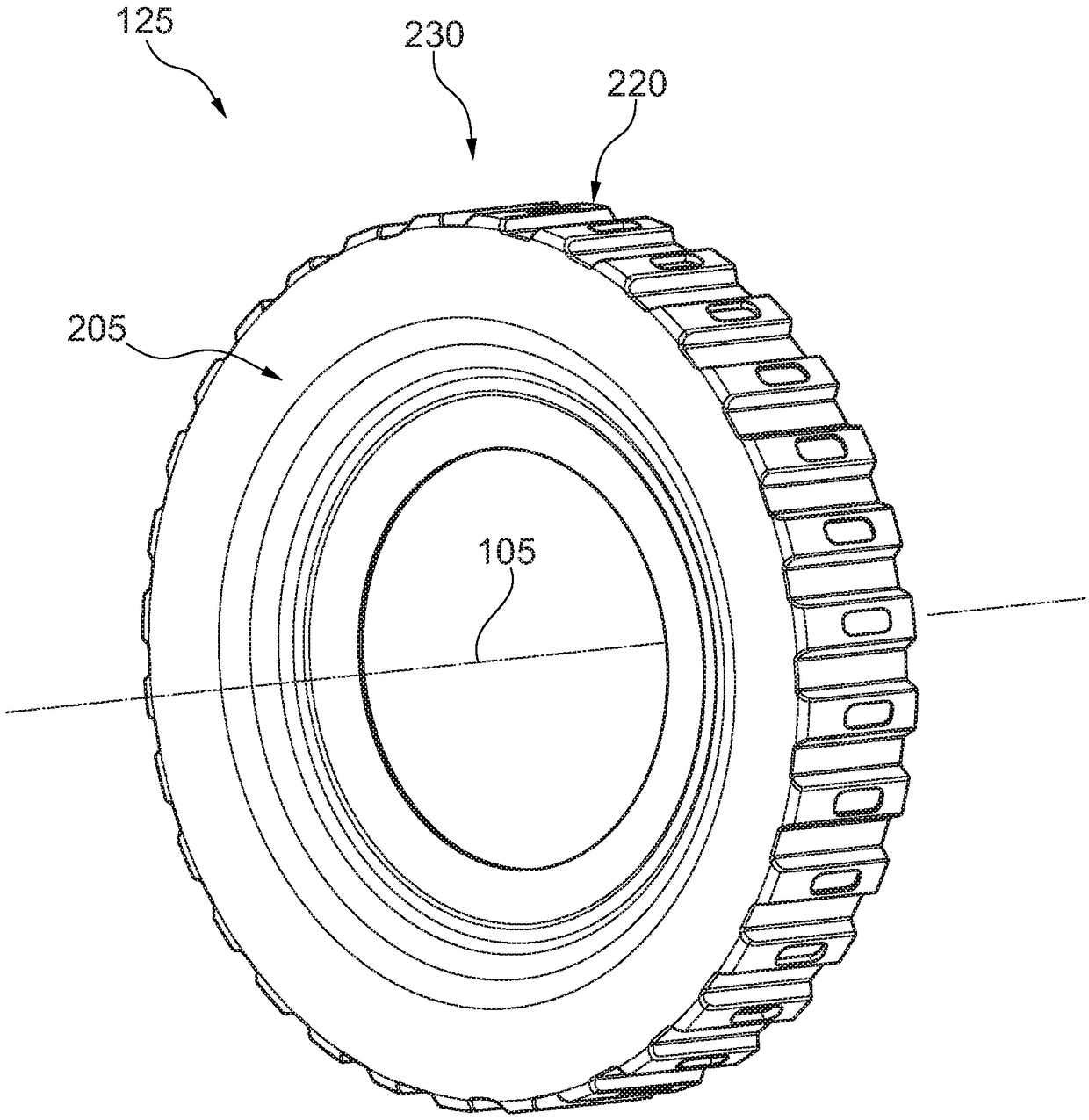

[0023] figure 1 A dual clutch 100 is shown with an axis of rotation 105 . The dual clutch 100 is preferably provided for operation in a liquid bath, in particular an oil bath, and comprises a radially inner clutch 110 and a radially outer clutch 115 , not all elements of which are shown separately. The input side of the inner clutch 110 and the input side of the outer clutch 115 are jointly integrated in a carrier 120 . Here, the support 120 comprises an inner support element 125 , an outer support element 130 and optionally a retaining element 135 . Radially inner carrier element 125 is preferably provided for introducing force or torque into dual clutch 100 .

[0024] The inner clutch 100 further comprises: a first friction element 140 having outer toothing for a torque-locking fit into the inner carrier element 125; and a second friction element 145 having outer teeth for a torque-locking fit into the inner Internal toothing on the output side (not shown) of the clutch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com