Sensor arrangement for determining at least one parameter of a fluid medium flowing through a channel

一种传感器组件、流体介质的技术,应用在测量仪器组件、测量流量/质量流量、液体/流体固体测量等方向,能够解决相对位置有波动等问题,达到窄位置公差、小耗费的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

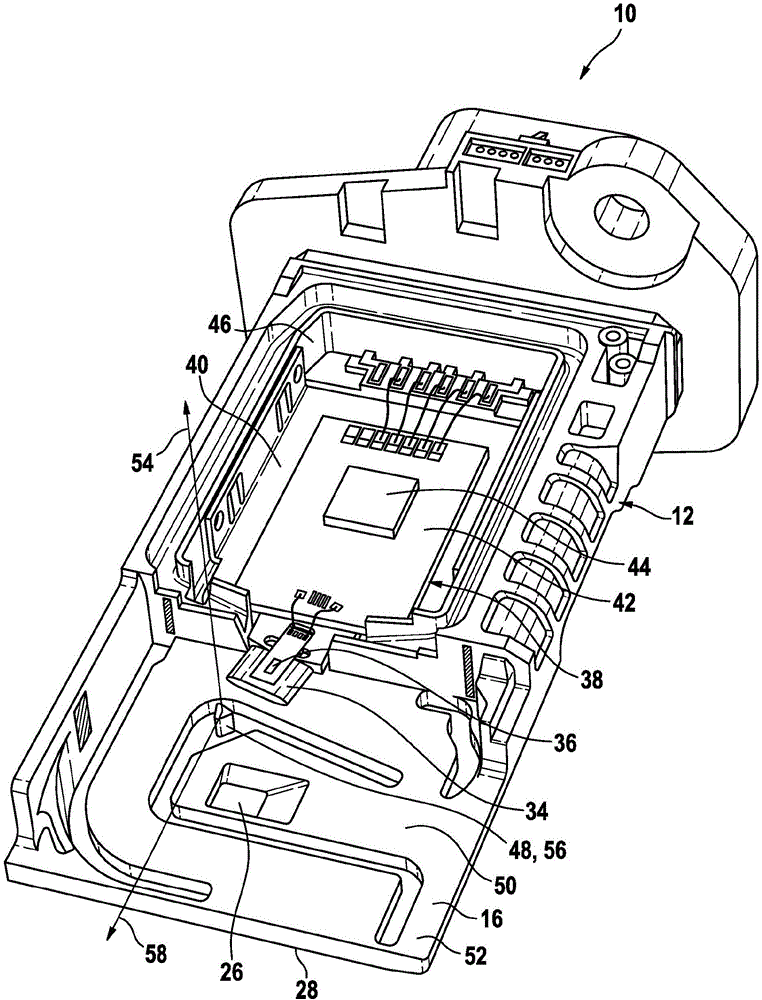

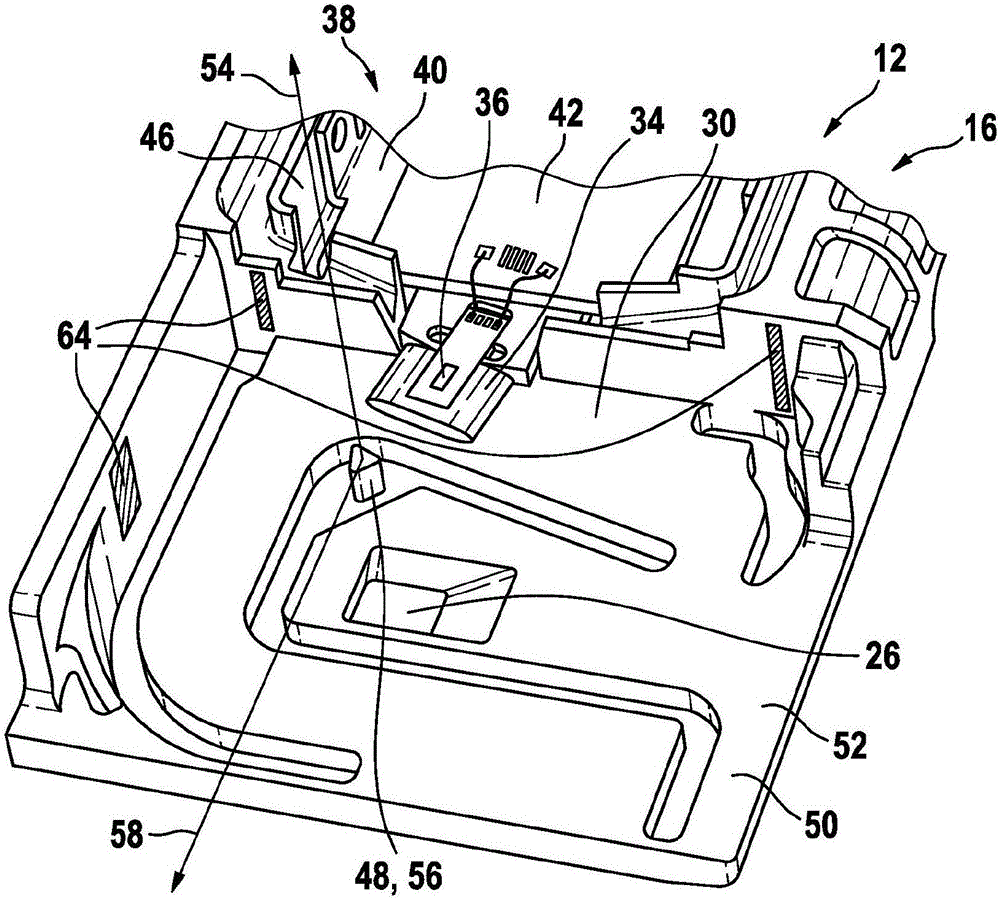

[0033] figure 1 A sensor assembly 10 for determining a parameter of a fluid medium flowing through a channel is shown. In the present exemplary embodiment, sensor arrangement 10 is designed as a hot-film air mass sensor and is particularly capable of sensing an intake air mass flow of an internal combustion engine. In this embodiment, the sensor assembly 10 includes a sensor housing 12 . The sensor housing 12 is designed as a plug-in probe, which can be inserted, for example, into a draft tube, in particular into an intake manifold of an internal combustion engine. A channel structure 14 of the type explained in more detail below is formed in sensor housing 12 . The sensor housing 12 has a housing body 16 and a cover 18 .

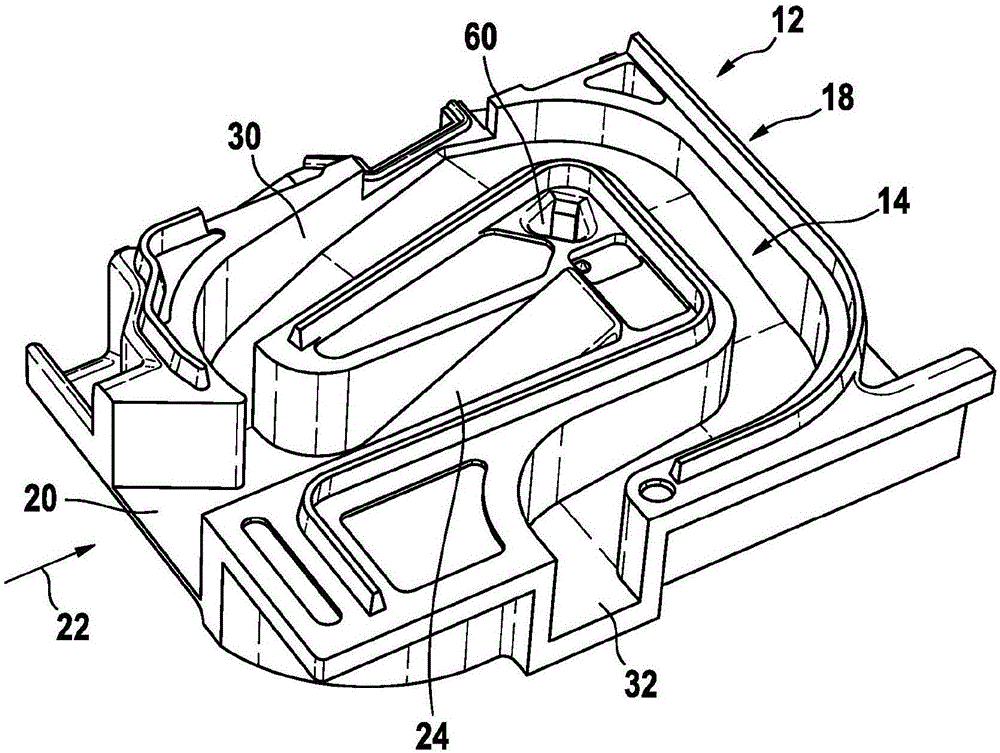

[0034] figure 2 A perspective view of the cover 18 is shown. The channel structure 14 is formed in the cover 18 . A representative amount of fluid medium can flow through the channel structure 14 via the inlet opening or inlet 20 which in the inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com