Fuel injection device with an assembly for connecting a fuel injection valve with a fuel guide part

A technology of fuel injection valve and guide components, which is applied in the direction of fuel injection device, special fuel injection device, mechanical equipment, etc., can solve problems such as complex structure, avoid direct contact, improve function and improve noise performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

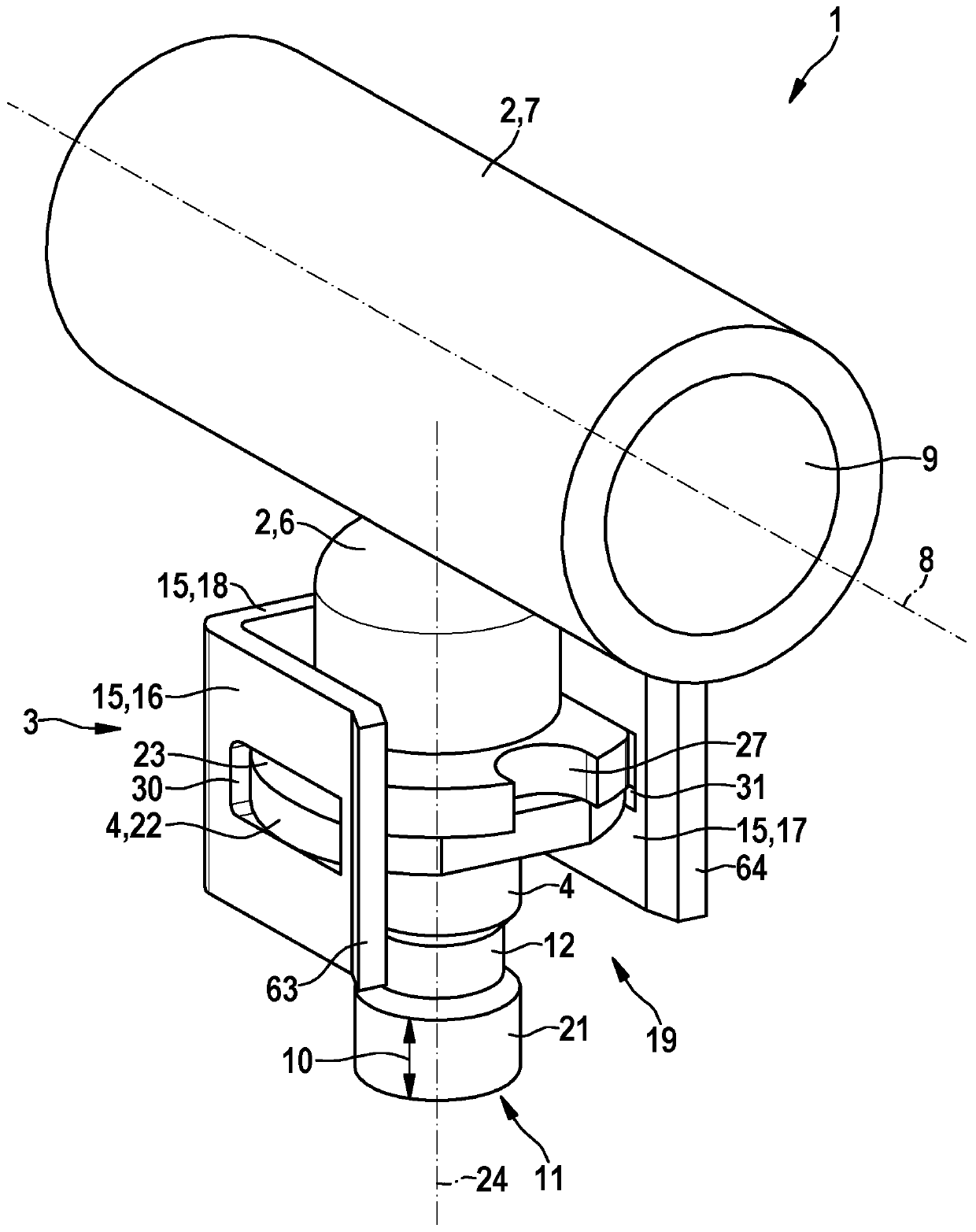

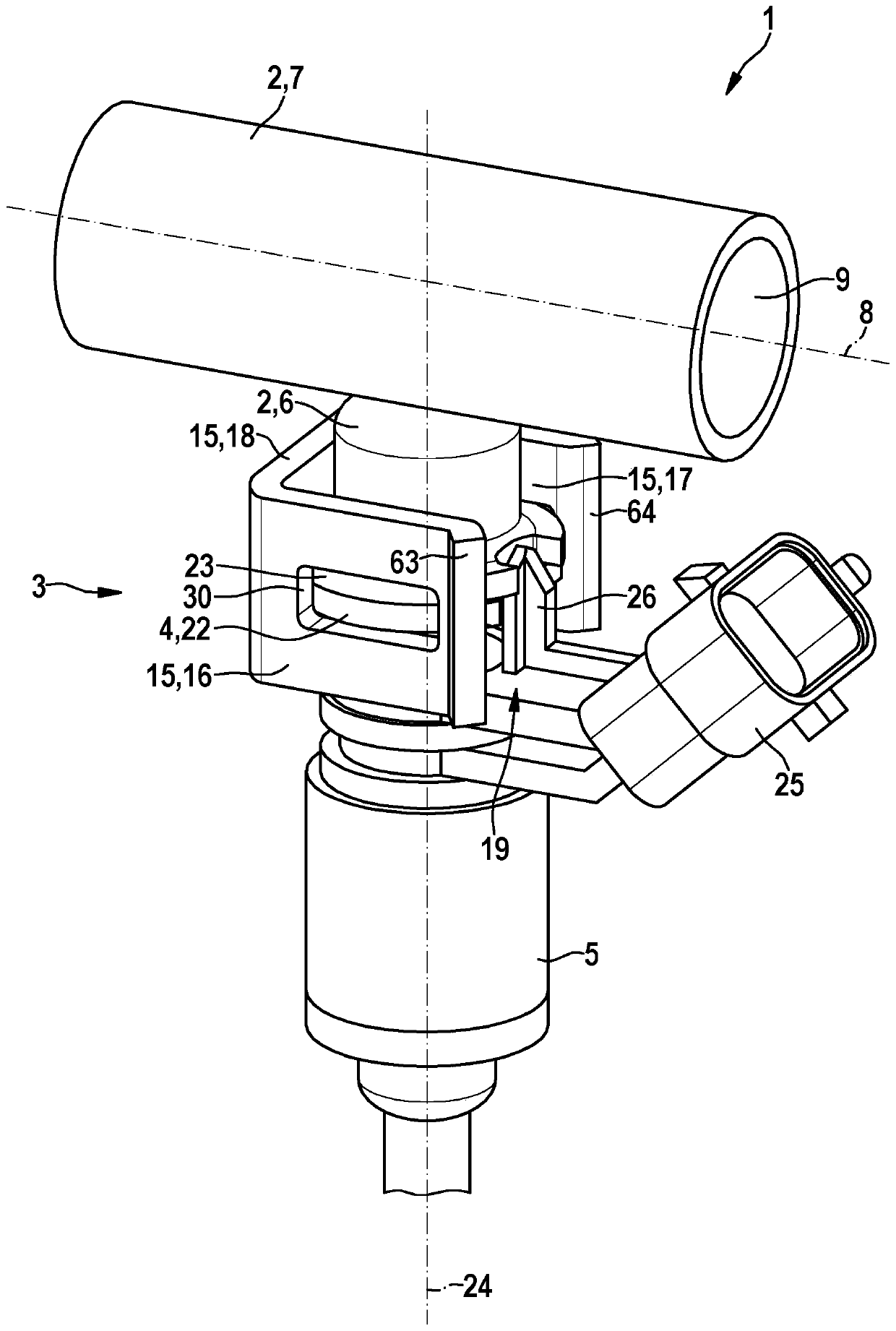

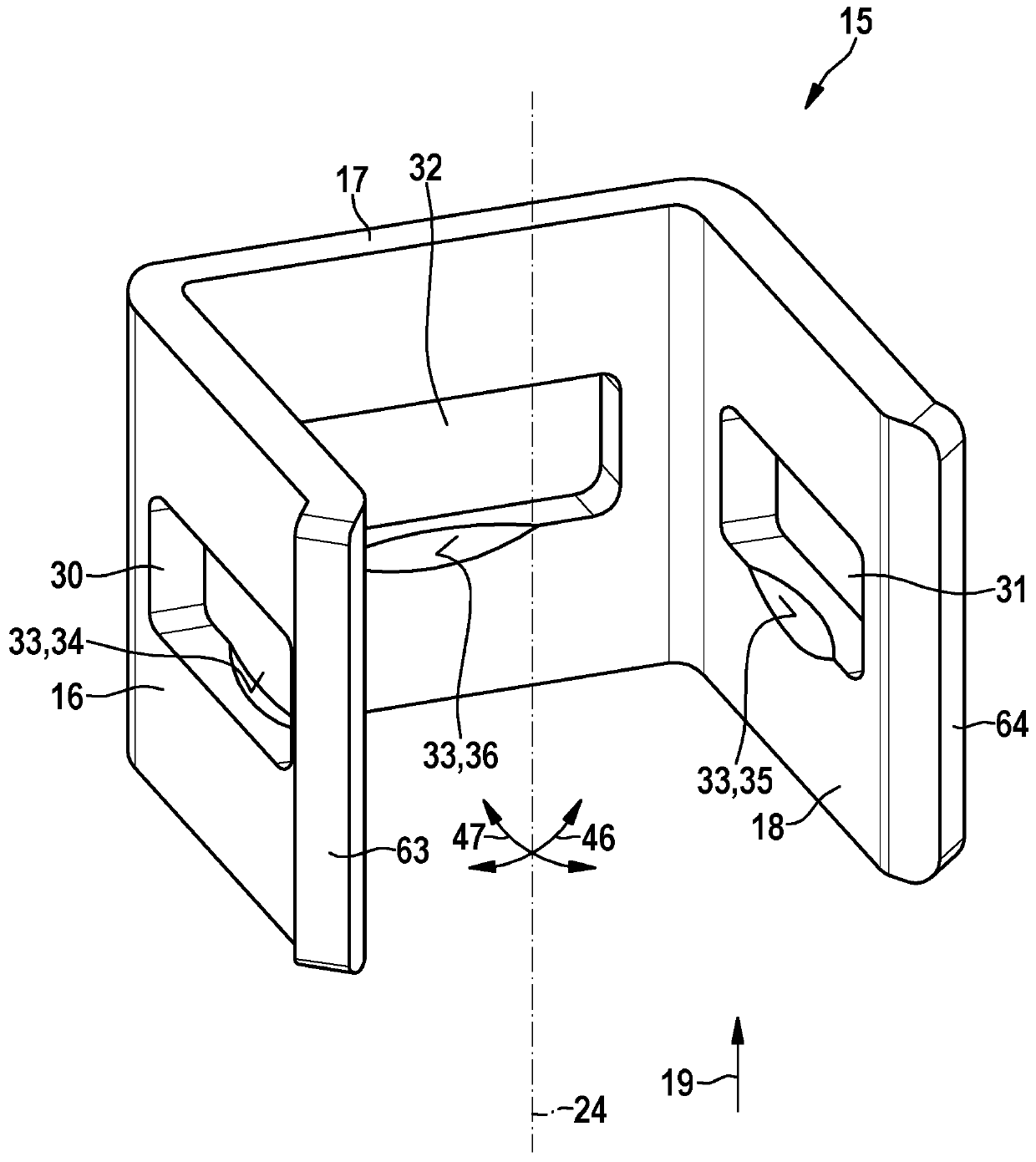

[0040] figure 1 A fuel injection system 1 with a fuel guide part 2 and an assembly 3 for connecting a fuel injection valve 5 ( figure 2 ) of the joint piece 4 is connected to the cup seat 6 of the fuel guide part 2 . The fuel guiding part 2 here has a tubular base body 7 and a cup 6 , wherein, in addition to the cup 6 , further cups are fastened to the tubular base 7 , preferably along the axial extension of the tubular base 7 superior. To simplify the illustration, only a section of the tubular base body 7 is shown here, wherein the tubular base body 7 extends along its axis 8 over a sufficient length.

[0041] In this exemplary embodiment, the tubular main body 7 can be part of the fuel-carrying component 2 designed as a fuel distributor 2 , in particular a fuel distribution rail 2 . The interior space 9 of the tubular base body 7 then serves as a fuel accumulator in order to store fuel under high pressure and to distribute the fuel via a corresponding number of cups 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com