A dual-channel water treatment method for a seawater industrialized circulating water system

A circulating water system and factory technology, applied in the field of fishery facilities and equipment, to achieve the effect of reducing adverse effects, high efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

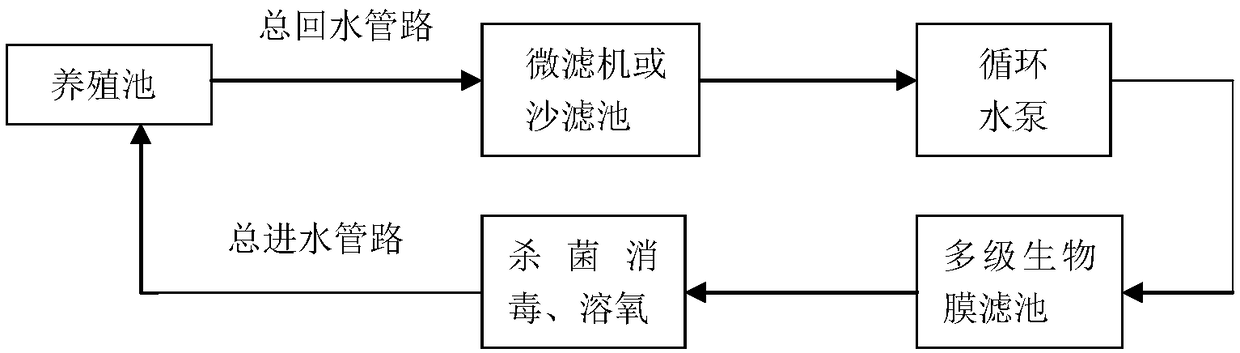

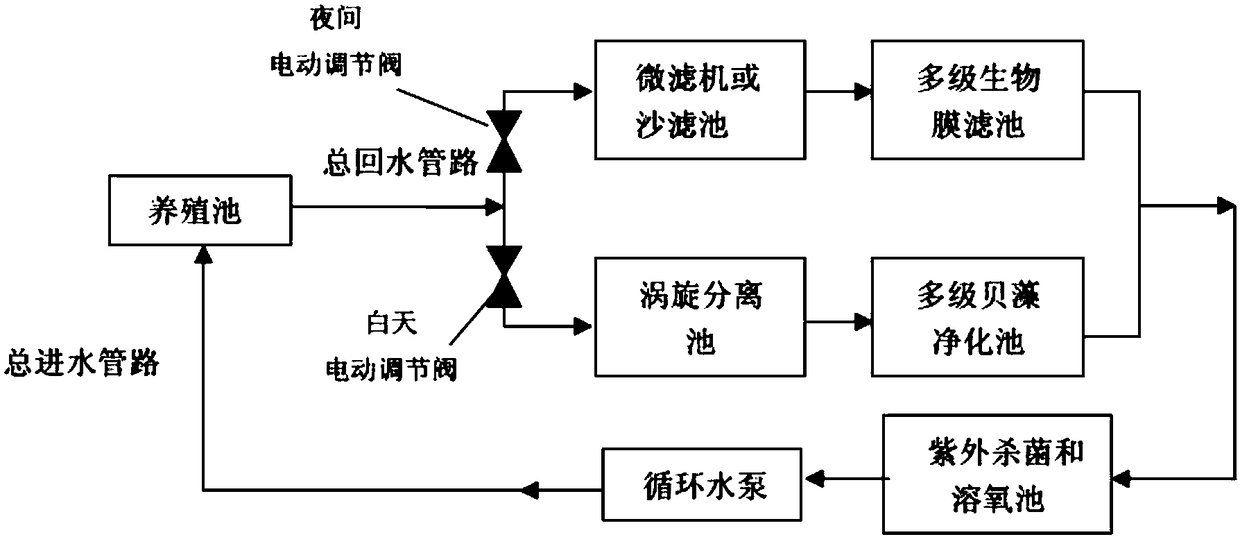

[0026] A double-channel water treatment method for a seawater industrialized circulating water system. This method is based on the biofilm method of water treatment in the industrialized circulating aquaculture system commonly used at present. The mechanism of phytoremediation and the principle of harmonious symbiosis of multi-trophic marine organisms such as fish, shrimp, shellfish, algae, and ginseng form a new method of dual-channel water treatment for industrial circulating water systems.

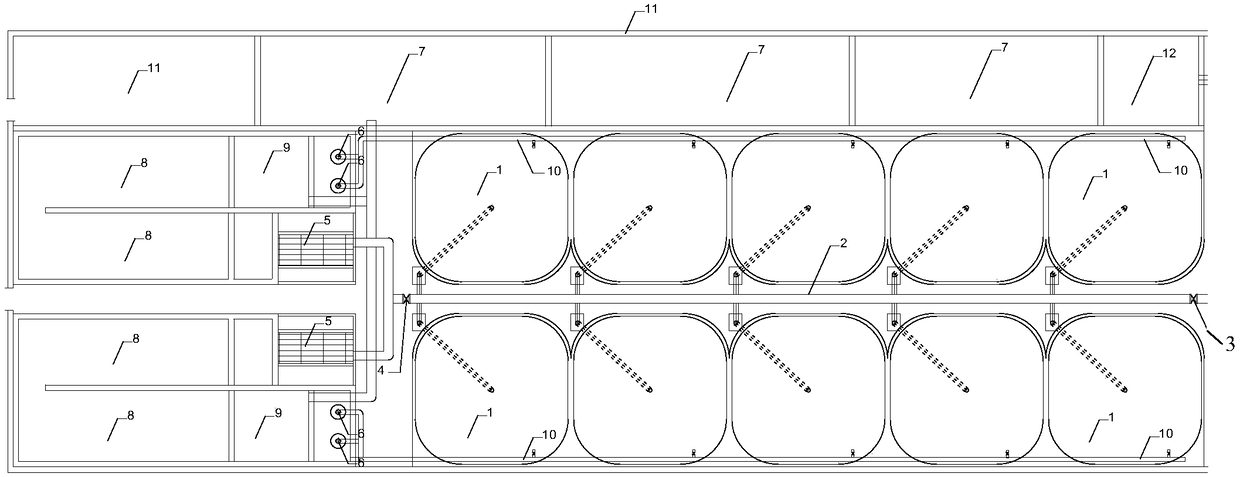

[0027] like figure 2 , 3 , 4, the breeding facility of the method includes a breeding pond 1, a total return water pipeline 2, an electric regulating valve 3 during the day, an electric regulating valve 4 at night, a microfilter or a sand filter 5, a circulating water pump 6, a multi-stage shellfish Algae purification tank 7, multi-stage biofilm filter tank 8, ultraviolet sterilization and dissolved oxygen tank 9, total water inlet pipeline 10, sunlight greenhouse 11 and vortex separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com