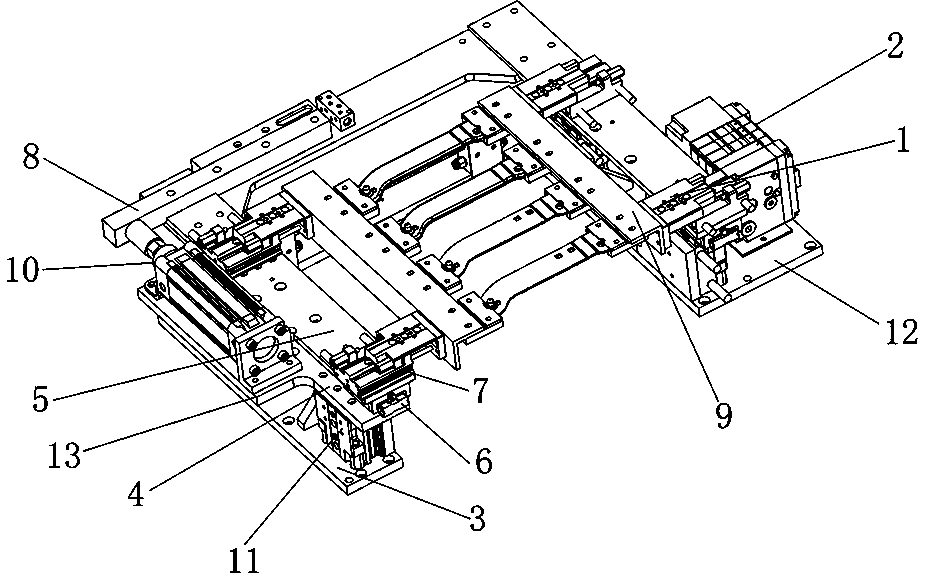

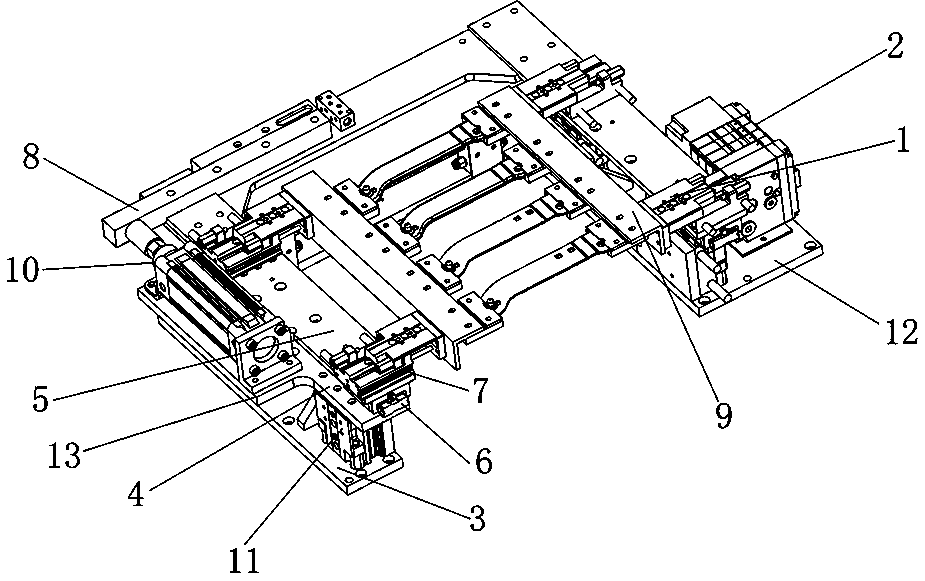

Small Pneumatic Transfer Manipulator

A manipulator and pneumatic technology, applied in the field of small pneumatic conveying manipulators, can solve the problems of low efficiency and poor safety, achieve huge market prospects, meet the requirements of safe and efficient operation, and widely use the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] The model of horizontal cylinder 1 is SMC CQ2B 63-100, the model of air valve 2 is SMC EX260, the size of installation base 3 is 456mm*90 mm*15 mm; the size of installation base 12 with ear plate is 460 mm*200 mm*15 mm, the size of the ear plate is 210 mm*120 mm; the size of the support plate 4 is 600 mm*50 mm*15 mm; the size of the support plate 13 with the ear plate is 456 mm*155 mm*15 mm, and the size of the ear plate is The size is 320mm*70mm; the size of the longitudinal slide rail 6 is 180mm*42mm*15mm; the size of the horizontal slide rail 7 is 72mm*42mm*15mm; the size of the connecting beam 8 is 540mm*40mm* 30mm; the beam size of the horizontal manipulator 9 is 545 mm*80 mm*10 mm; the model of the vertical cylinder 10 is SMC MXH 20-60Z; the model of the ascending cylinder 11 is SMC MXH 20-60Z.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com