Equipment for precisely carving light guide plate by using laser

A light guide plate and laser technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of light equipment, reducing lost time and maximizing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

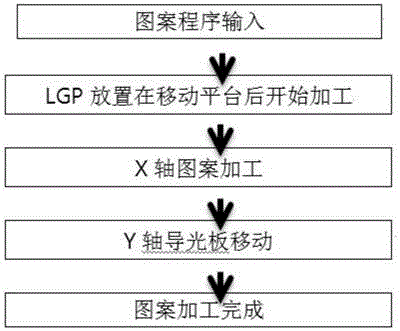

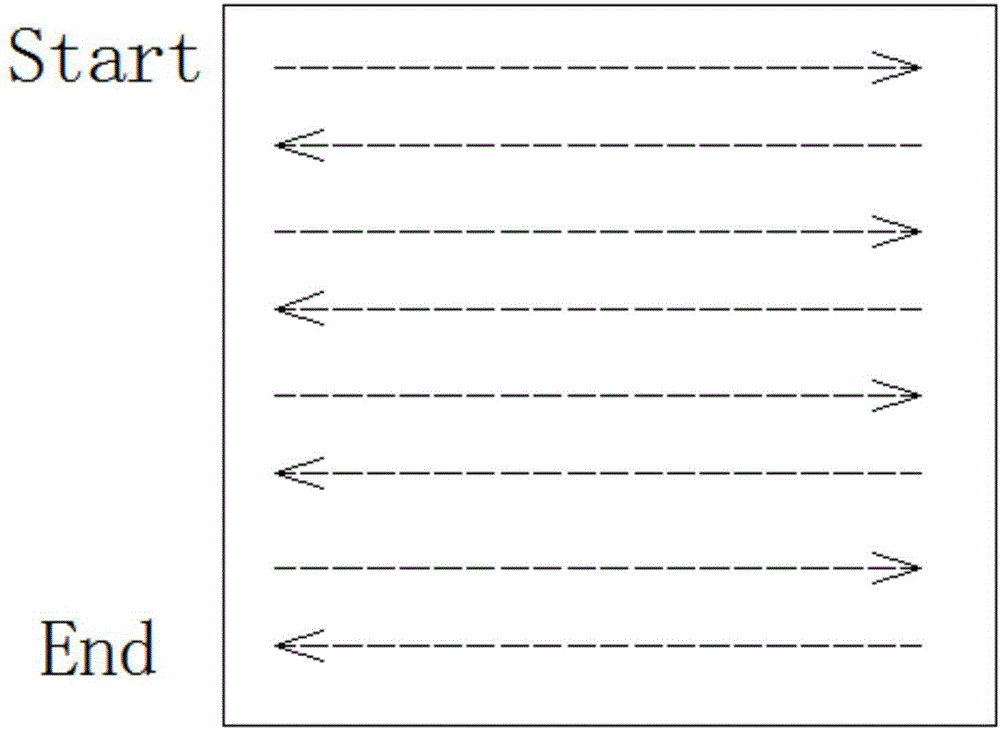

Method used

Image

Examples

Embodiment Construction

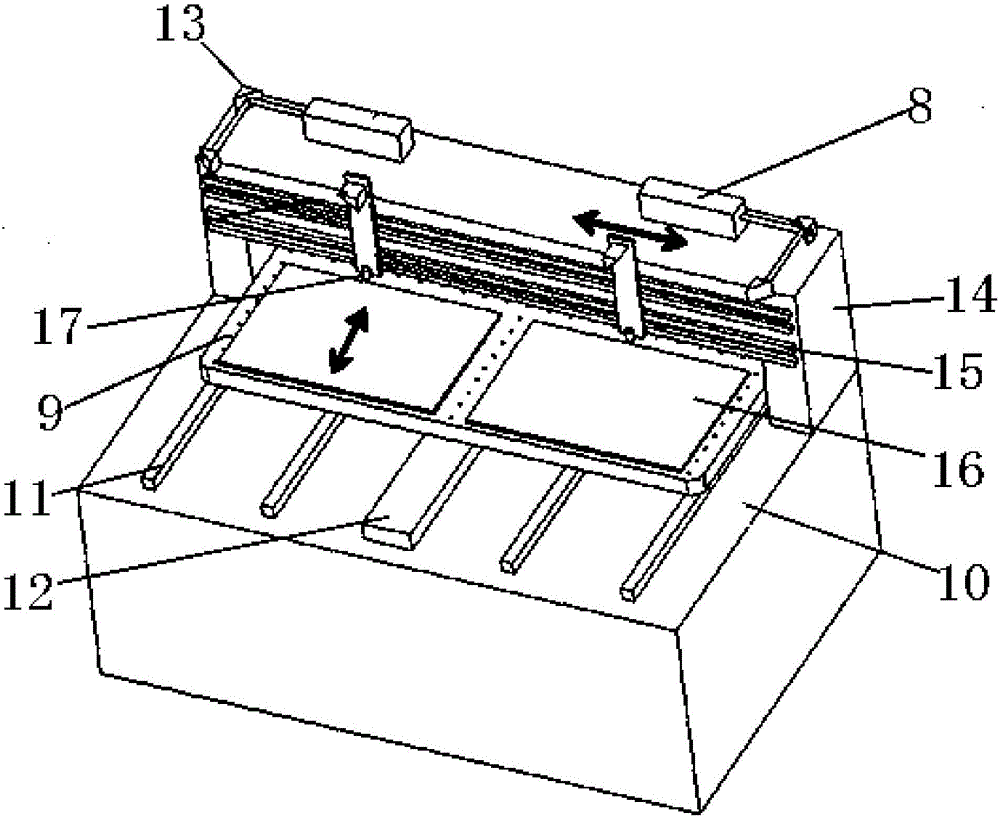

[0030] like Figure 4 — Figure 6 As shown, a device for precision engraving on a light guide plate with a laser, including a workbench 1, the top surface of the workbench 1 is provided with multiple guide rails 2 along the Y axis, that is, the horizontal front and rear directions, and the guide rails 2 of the workbench 1 are slidably equipped with The mobile platform 3, the top surface of the mobile platform 3 is used to carry the light guide plate 4, and the workbench 3 is provided with an optical rotation plate device 6 and a laser emitting device 5 from bottom to top in sequence;

[0031] Wherein the laser emitting device 5 includes a support plate 5.1 placed horizontally on the back and upper side of the workbench 3, the top surface of the support plate 5.1 is provided with a laser emitter 5.2, three groups of reflecting mirrors 5.3, 5.4, 5.5, and the first group of reflecting mirrors in the laser emitting device 5 The mirror 5.3 is located on the outgoing light path of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com