Refilling device for watch escape wheel

A technology for refilling and reeling, which is applied to the field of renewing devices for watch escapement reels, can solve the problems of affecting production progress, difficulty in operation, low efficiency, etc., so as to improve production efficiency, improve processing accuracy, and reduce missed work situations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

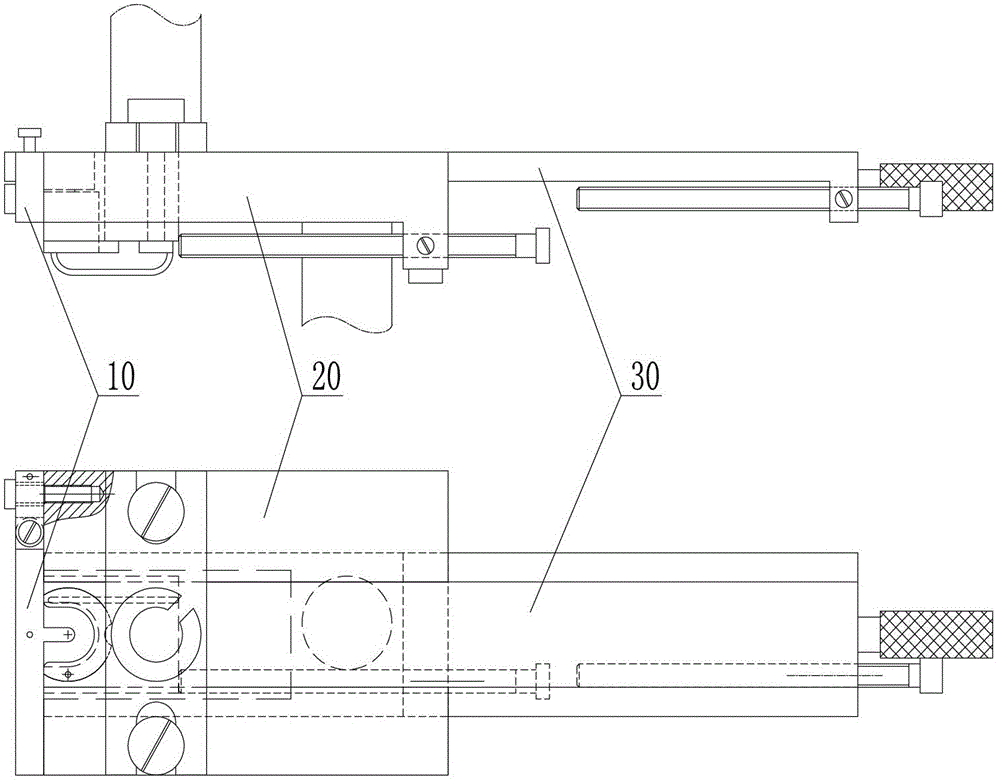

[0034] Such as figure 2 Shown: the material refilling device of the watch escapement wheel of the present invention is mainly used for refilling when the escapement wheel is grinding the punching surface; One side of the sorting door 10 is connected with the slideway 20 by screws; the refilling hand 30 is installed in the groove of the slideway 20 and can move horizontally along the slideway.

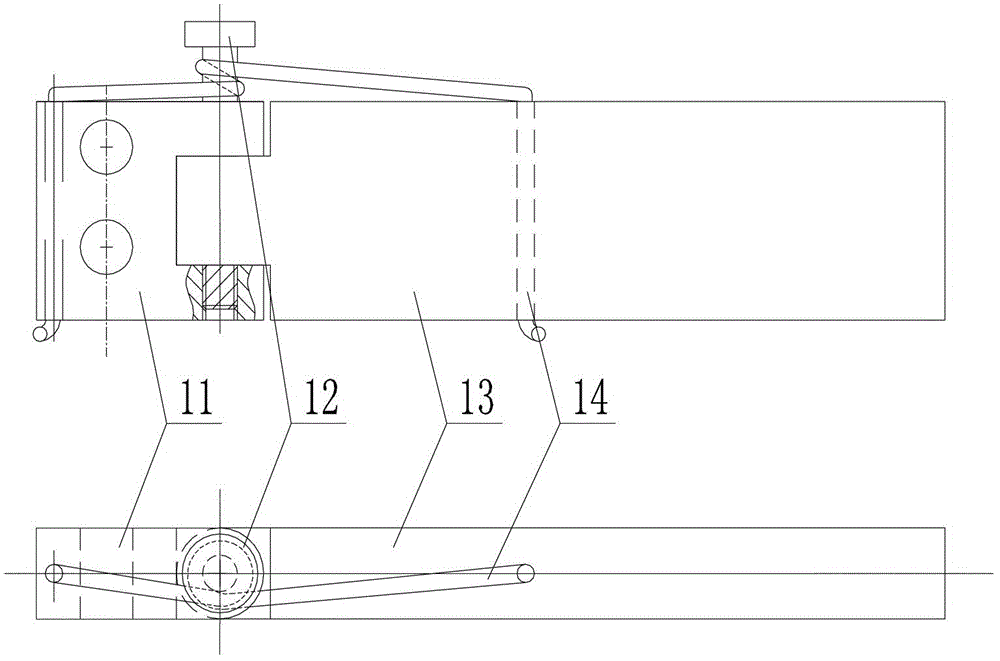

[0035] Such as Figure 3 to Figure 5 As shown: the finishing door 10 includes a connecting plate 11, a pin shaft 12, a material retaining plate 13, and a spring 14; one side of the connecting plate 11 is connected to the slideway 20 with screws through two C holes, and the other side is connected by a pin shaft 12 is connected with the baffle plate 13; the pin 12 is screwed in the threaded hole of the connecting plate 11; one end of the spring 14 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com