Mechanical arm for installing internal spring of machine and working method thereof

A technology of mechanical arms and working methods, which is applied in the directions of manipulators, metal processing, manufacturing tools, etc., can solve the problems of poor installation of springs, and achieve the effects of avoiding damage to springs, convenient grasping of springs, and solving problems of poor installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

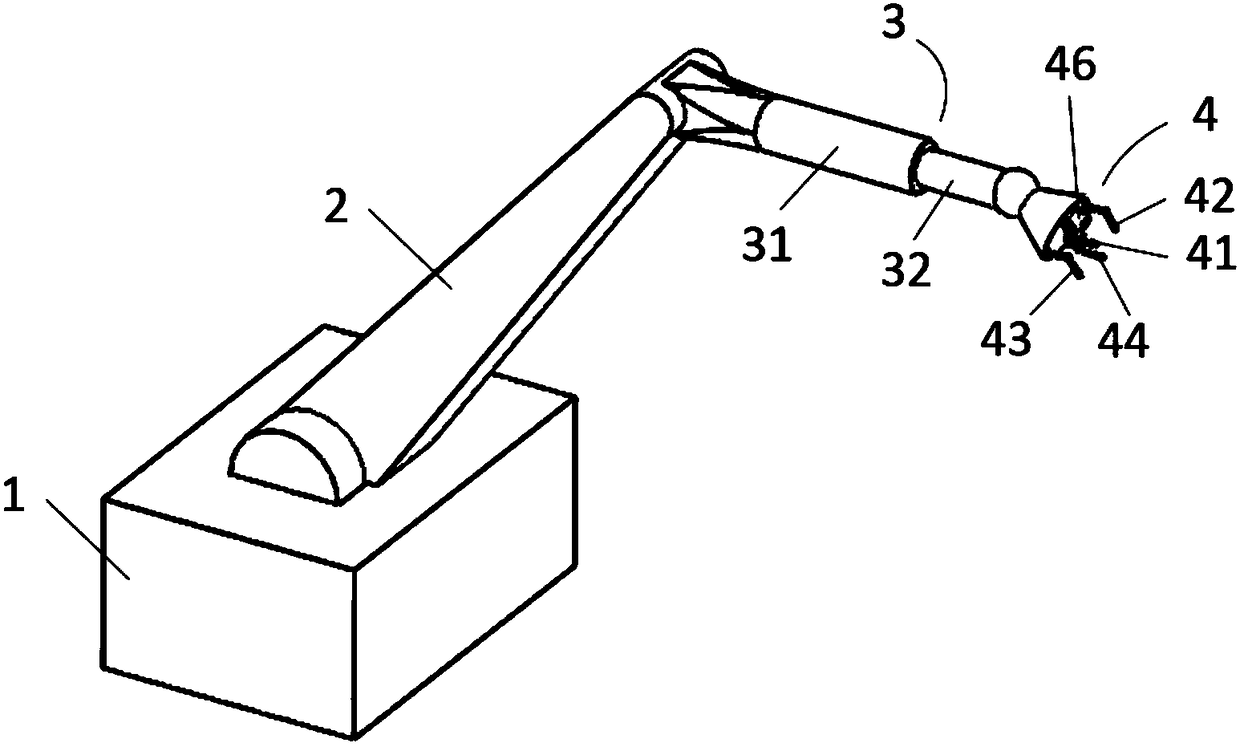

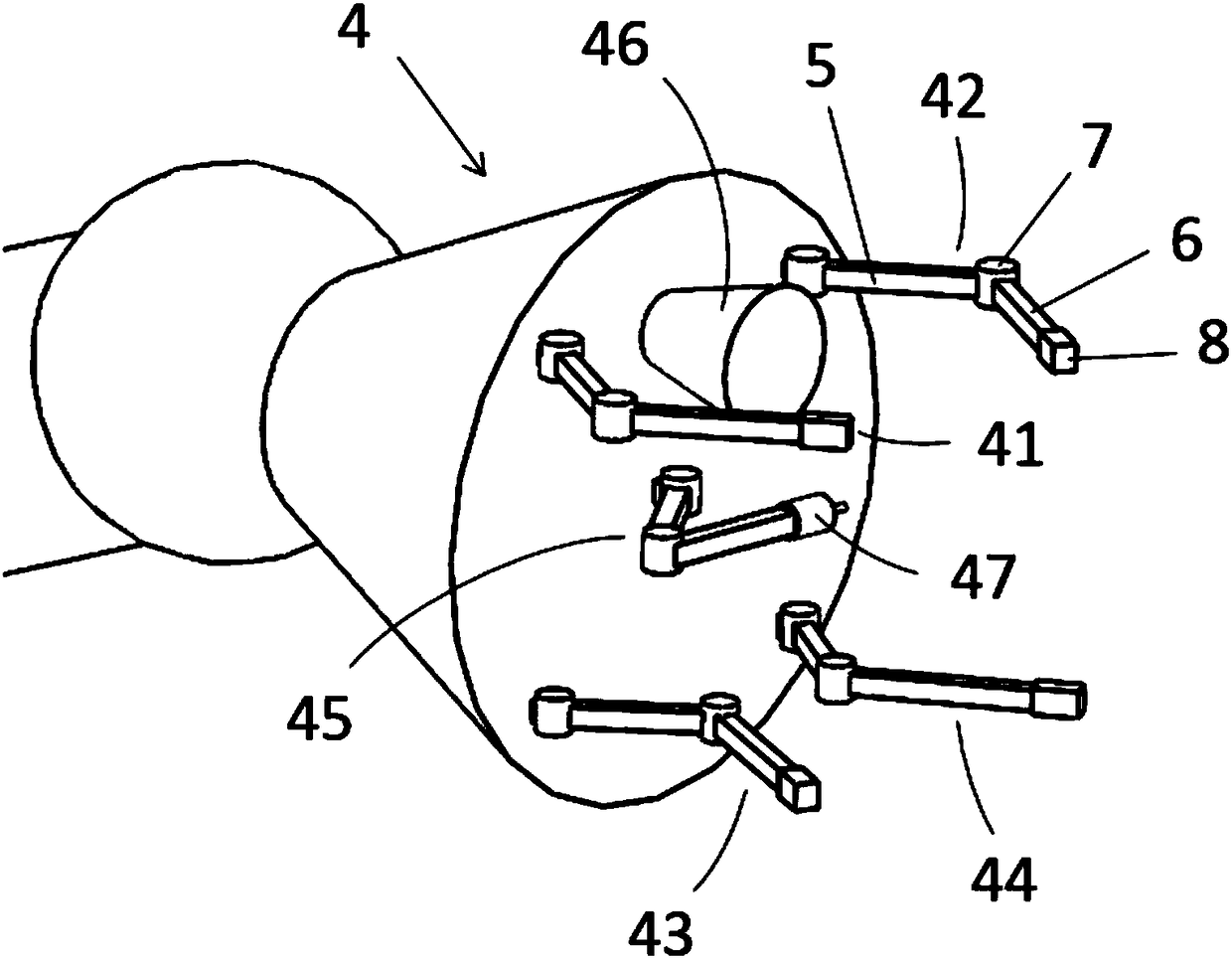

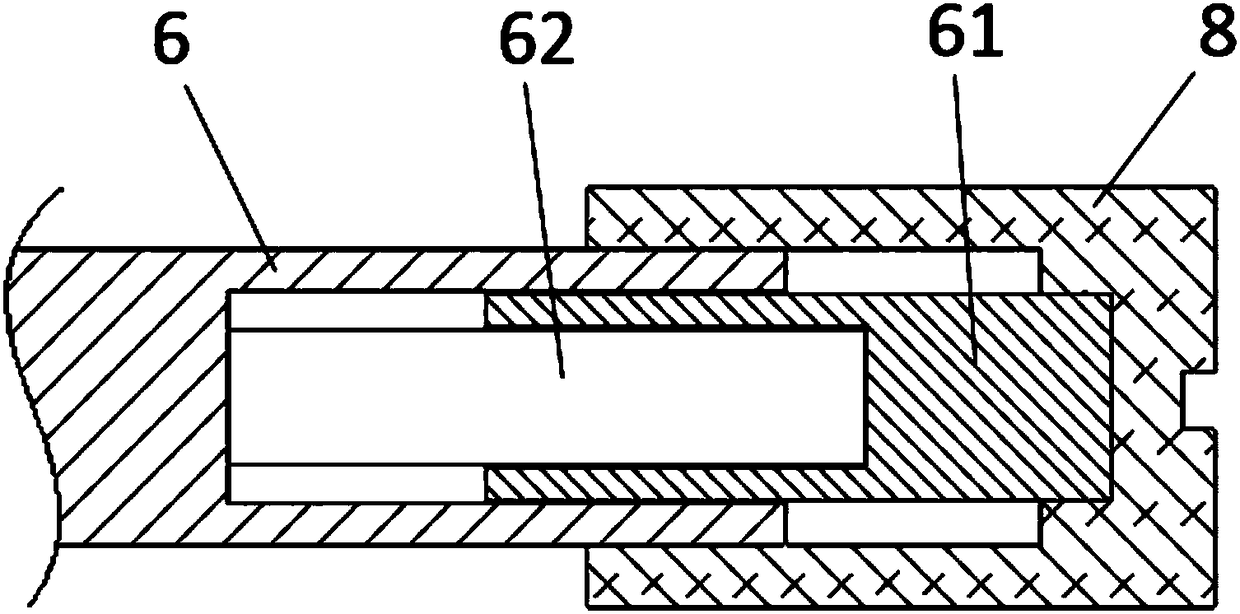

[0021] A mechanical arm for installing the internal spring of the machine of the present invention, such as Figure 1 to Figure 3 As shown, it includes a base 1, a first mechanical arm 2, a second mechanical arm 3, a manipulator 4, a driving device and a control device; the manipulator 4 includes a spring left jaw 41 and a spring right jaw 42 oppositely arranged, A pair of oppositely arranged auxiliary left jaws 43, auxiliary right jaws 44, and detection jaws 45, wherein the spring left jaws 41, spring right jaws 42, auxiliary left jaws 43 and auxiliary right jaws 44 all include upper jaws The jaw 5, the lower jaw 6 and the jaw joint 7 connecting the two, an electromagnetic sucker 46 is provided between the spring left jaw 41 and the spring right jaw 42, and a pressure sensor 47 is provided at the end of the detection jaw 45; The first mechanical arm 2, the second mechanical arm 3 and the manipulator 4 are all connected to the driving device, and the electromagnetic chuck 46, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com