Manipulator for installing various springs and its working method

A technology of manipulators and spring grippers, which is applied in the field of manipulators, can solve the problems of poor installation of springs, and achieve the effects of avoiding damage to springs, solving poor installation, and convenient grabbing of springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

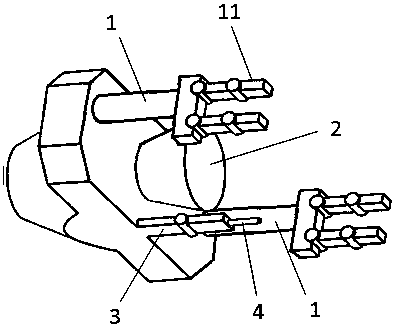

[0019] A manipulator for installing multiple springs of the present invention, such as figure 1 As shown, it includes a manipulator base, an external control system, two spring clamping jaws 1, an air suction cup 2 and a detection claw 3, wherein the two spring clamping jaws 1 are oppositely arranged at both ends of the manipulator base, and the suction suction cup 2 Set between two spring clamping jaws 1, each spring clamping jaw 1 includes two grasping fingers 11, the end of the detection jaw 3 is provided with a load cell 4, the load cell 4 is a pressure sensor, and the spring clamp jaws 1 is equipped with a position detection device, and the external control system includes an alarm device, a counting device, a driving device and a control device; the spring gripper 1, the grasping finger 11, the suction cup 2 and the detection claw 3 are all connected with the driving device The load cell 4, the alarm device, the counting device, the position detection device, and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com