Automobile electronic vacuum pump support

A technology for automotive electronics and vacuum pumps, applied in the arrangement of pumps/compressors, etc., can solve the problems of large bracket mass, loud noise and looseness, and achieve the effect of ensuring strength, reducing noise, and strengthening firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be emphasized that the following embodiments are illustrative, not restrictive, and should not be used as limitations of the present invention.

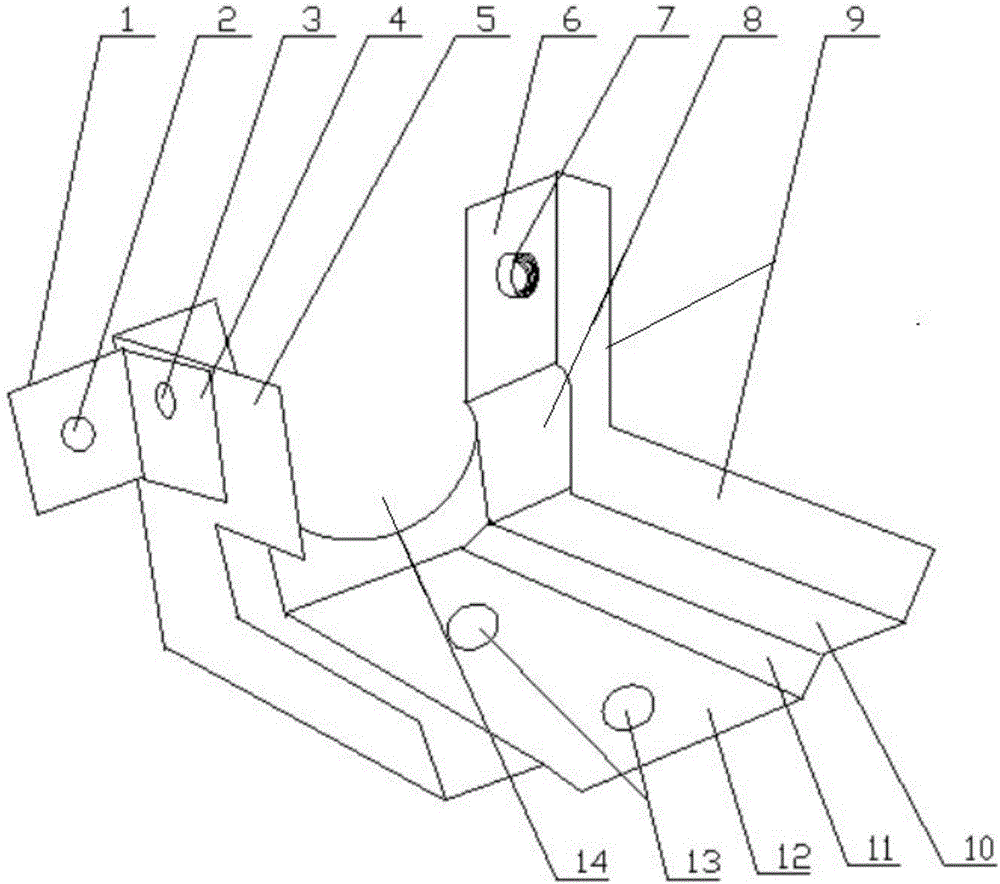

[0012] A car electronic vacuum pump bracket, such as figure 1 As shown, the fixed base plate 10 is included, and two front and rear base plate installation holes 13 are formed in the middle of the fixed base plate. , the front mounting holes are formed on the fixed front side plates on both sides of the arc-shaped card slot respectively. The innovation of the present invention is that the fixed bottom plate and the fixed The side slats 9 formed at an angle of 110°-120° to the plane of the front side plate are symmetrically punched out in the middle of the fixed base plate to form a bottom plate slope 11 which is 110°-120° downward to the plane of the fixed base plate, and a concave groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com