Automatic packaging machine

A packaging machine and automatic technology, applied in the field of catering packaging, can solve the problems of secondary pollution, food leakage, and increased labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

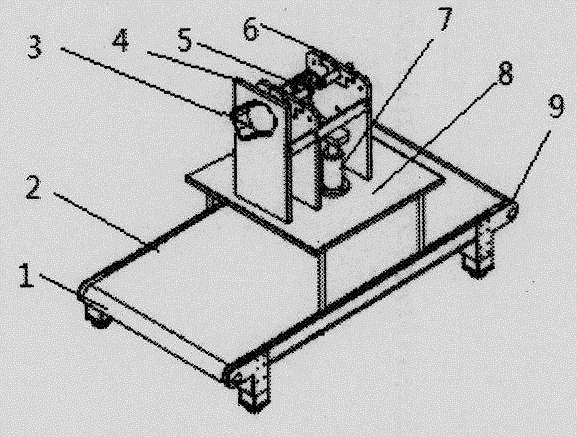

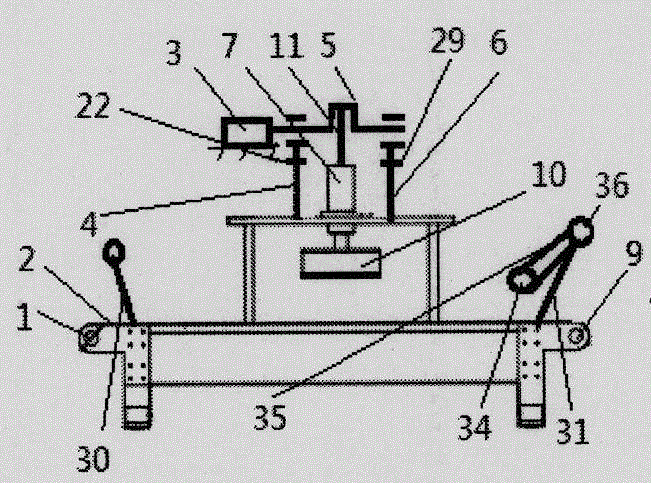

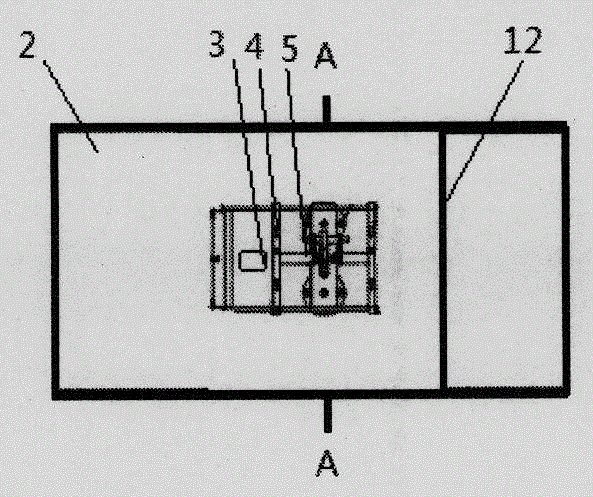

[0024] The automatic packaging machine is mainly composed of a transmission mechanism, a thermoplastic mechanism, a laminating mechanism, an easy-to-tear mechanism, and a PLC control system.

[0025] The transmission mechanism is composed of the first speed regulating motor 3, the crankshaft 5, the connecting rod cover 7, the connecting rod 11, the second speed regulating motor and the synchronous toothed belt pulley 4, the synchronous toothed belt 35, the third speed regulating motor 37, the joint The shaft device 17, the first roller shaft 1, the conveyor belt 2, and the second roller shaft 9 are composed; the first speed regulating motor 3 and the crank shaft 5 are coaxially connected, and the second speed regulating motor 34 is coaxially connected with the synchronous toothed pulley , the third speed regulating motor 37, coupling 17 are coaxially connected with the first roller shaft 1; the first roller shaft 1, the conveyor belt 2, and the second roller shaft 9 form a box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com