Blast-furnace high-blast temperature energy-saving emission-reduction combined system

A technology of energy saving and emission reduction, combined system, applied in blast furnace details, blast furnace, blast furnace parts and other directions, can solve the problems of poor energy saving effect, pollution, emission, etc., achieve simple structure, improve energy saving and emission reduction effect, increase The effect of high air temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

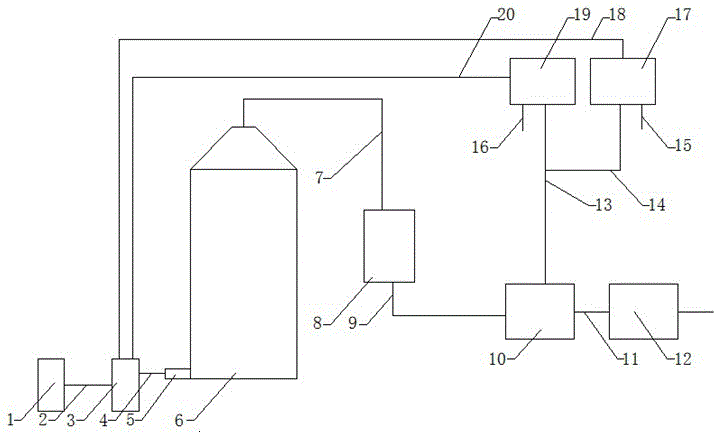

[0019] Specific embodiments: when the combustion furnace 6 is working, it will produce mixed smoke with heat, and these mixed smoke with heat will enter the secondary combustion device 8 through the mixed smoke channel pipe 7 at the top of the combustion furnace 6, and these mixed smoke with heat will enter the secondary combustion device 8. The mixed smoke is undergoing secondary combustion in the secondary combustion device 8, which can convert the toxic carbon monoxide in the mixed smoke into nontoxic carbon dioxide, and can also increase the heat of the mixed smoke.

[0020] After the secondary combustion, the mixed smoke passes through the mixed smoke outlet pipe 9, reaches the gas heat exchanger 10, and is transformed by the gas heat exchanger 10, and the mixed smoke forms air and exhaust gas with heat.

[0021] The waste gas in the gas heat exchanger 10 reaches the waste gas dedusting device 12 through the waste gas outlet pipe 11. After the waste gas is treated by the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com