Ship fire extinguishment and explosion suppression system

A firefighting and marine technology, applied in fire rescue, muffler device, fixed tubular duct assembly, etc., can solve problems such as aggravating fire hazards, difficulty in direct utilization of ship exhaust, etc., achieving low cost, reducing particulate matter and harmful toxic gases. The effect of discharge, efficient total submersion inerting and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

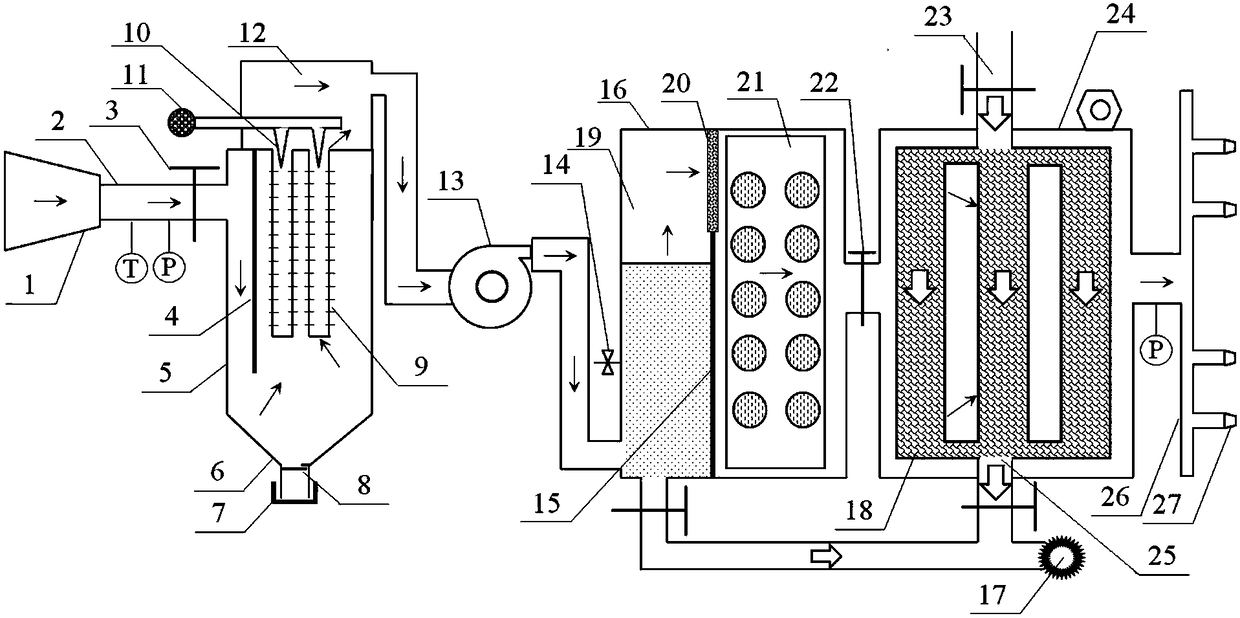

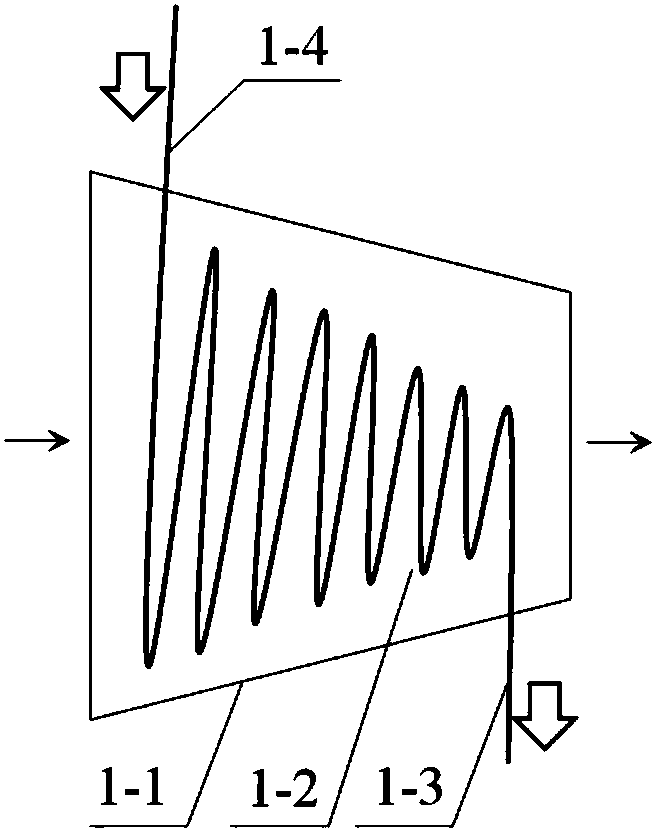

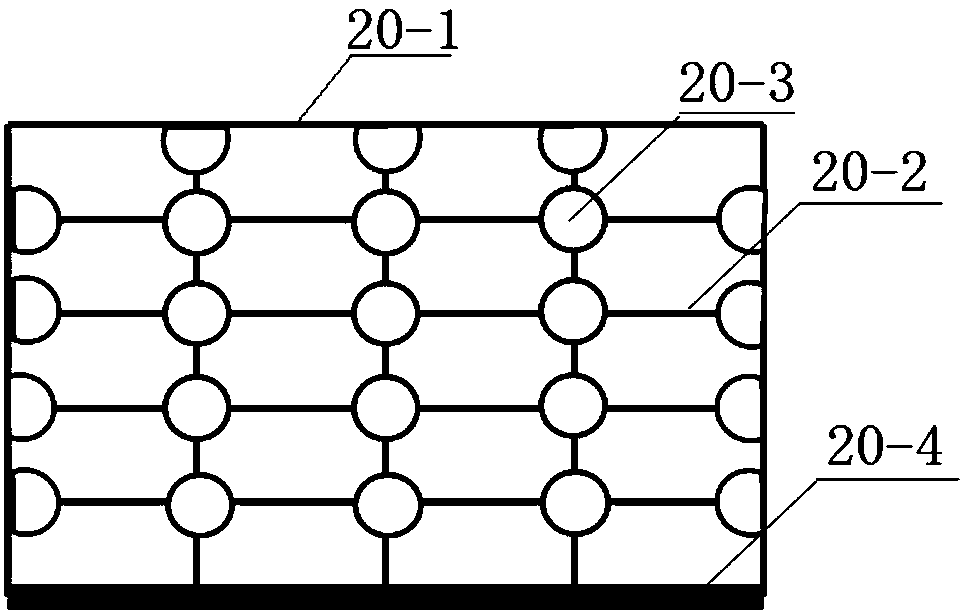

[0026] Such as figure 1 The shown fire-fighting and explosion-suppression system for a ship includes a particle trap 5, a desulfurization and degassing device 16, and a heat exchange device; the top of the particle trap 5 is provided with a clean air chamber 12, and the middle part is provided with a dust removal cylinder, The lower part is provided with a conical funnel 6, and the outlet of the conical funnel 6 is provided with a bottom cover 7; the upper side wall of the dust collector is provided with an air inlet I, and the air inlet I communicates with the ship exhaust gas collection cover 1 through a pipe 2 , there is a pre-valve 3 on the pipeline 2, and the particle baffle 4 and the filter cartridge 9 inside the dust collector are fixedly installed on the top of the dust collector. There is a nozzle 10 located in the clean gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com