Method for improving mechanical properties of 301LN austenitic stainless steel

A technology of austenitic stainless steel and mechanics, which is applied in the field of stainless steel preparation, can solve problems such as low yield strength and coarse grain, and achieve the effect of easy industrial production and remarkable effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0024] First, this embodiment uses the following equipment: the hot rolling mill is a φ450 hot rolling mill, the cold rolling mill is a φ325×400mm four-roll straight-drawn reversible cold rolling mill, and the annealing furnace is a box-type resistance furnace for heat treatment.

[0025] The specific operations for improving the mechanical properties of 301LN austenitic stainless steel in this embodiment are as follows:

[0026] Take the composition (wt.%) of 301LN austenitic stainless steel as follows: C is 0.017, Si is 0.52, Mn is 1.29, Cr is 17.3, Ni is 6.5, S is 0.025, P is 0.044, Mo is 0.15, N is 0.15 , The rest is Fe and unavoidable impurities.

[0027] The 301LN austenitic stainless steel ingot with the above composition is forged into a billet with a thickness of 45-50mm. The billet is heated with the furnace to 1200°C-1230°C and kept for 2.5-3.5...

PUM

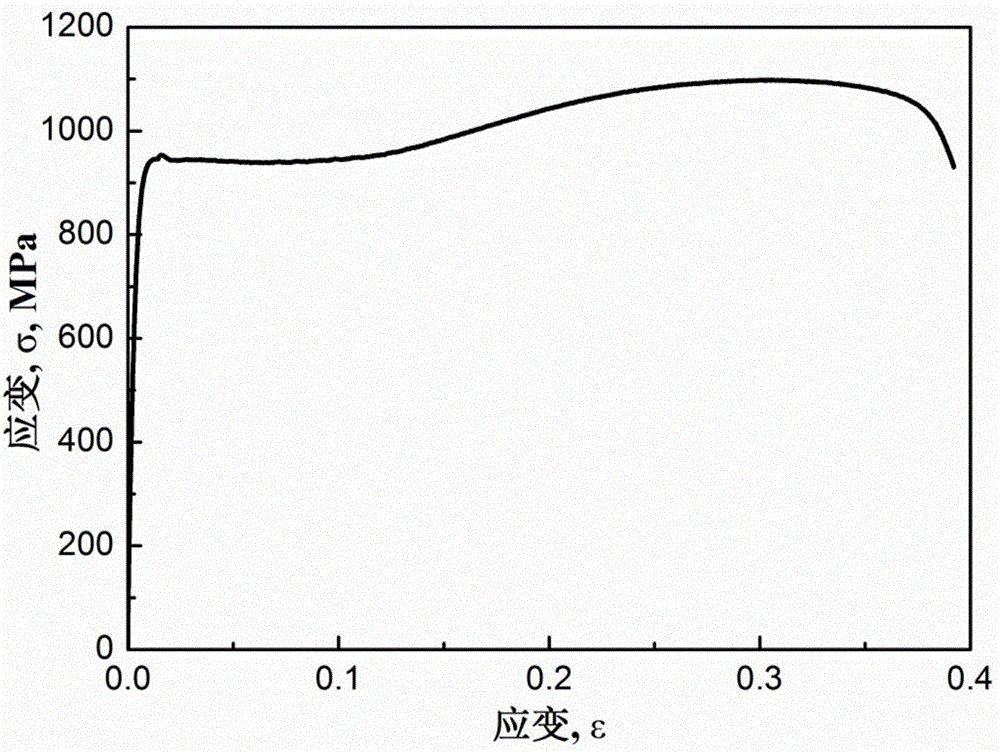

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com