Wave energy power generation device

A technology for power generation and wave energy, applied in electromechanical devices, ocean energy power generation, electrical components, etc., can solve the problems of high delivery and recovery costs, difficult dynamic sealing, low work efficiency, etc., to reduce delivery and recovery costs and improve reliability. The effect of sex, lead convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and specific embodiments.

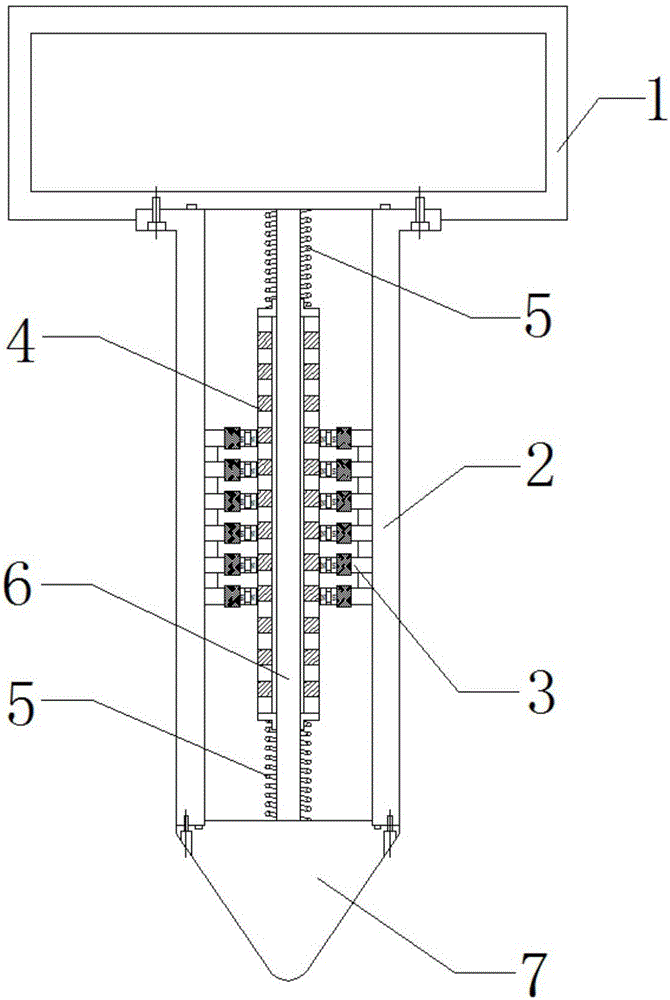

[0029] Such as figure 1 As shown, the wave energy power generation device of the present invention includes a float 1, a casing 2, a stator 3, a mover 4, a spring 5, a mover slide 6 and a tapered end cover 7. The float 1 and the tapered end cover 7 are located at the two ends of the casing 2 and form a sealed cavity with the casing 2. The stator 3, the mover 4, the spring 5 and the mover slide 6 are sealed inside the casing 2.

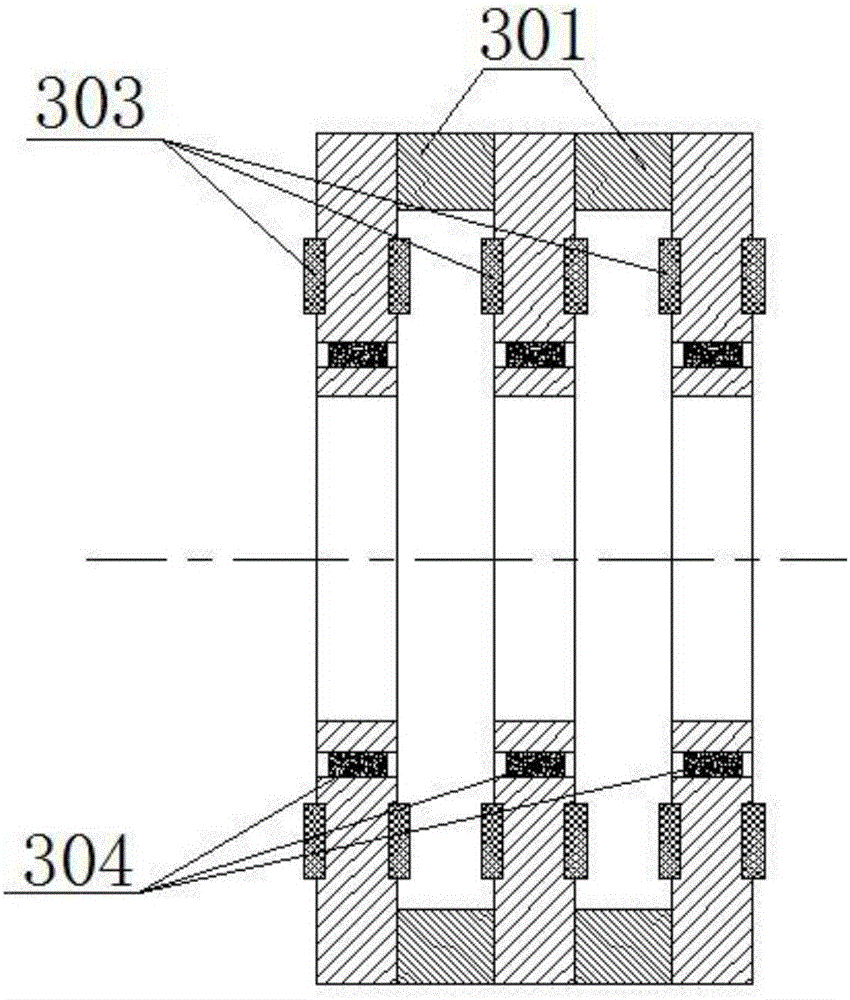

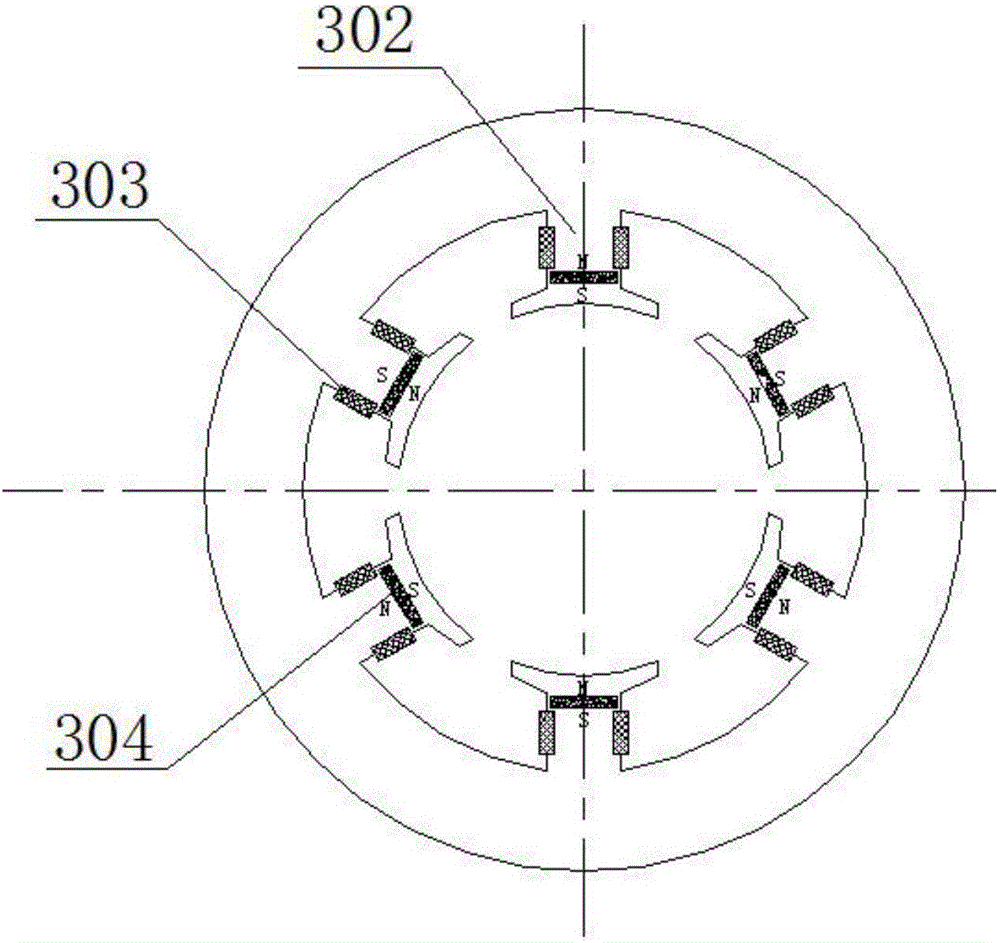

[0030] Such as figure 1 Or as shown in FIG. 2, the stator 3 has a cylindrical structure, which is formed by alternately stacking a plurality of stator units and stator magnetic isolation rings 301 with the same thickness in the axial direction. A certain number of stator teeth 302 are evenly distributed inside the stator unit, and coils 303 are wound on the stator teeth. A square hole is opened on the top of the stator tooth 302, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com