Transmission head cover assembly

A transmission and top cover technology, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of complex processing technology, complex structure and functions, and inaccurate gear selection, etc., and achieve convenience Symmetrical layout, compact structure, precise gear selection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

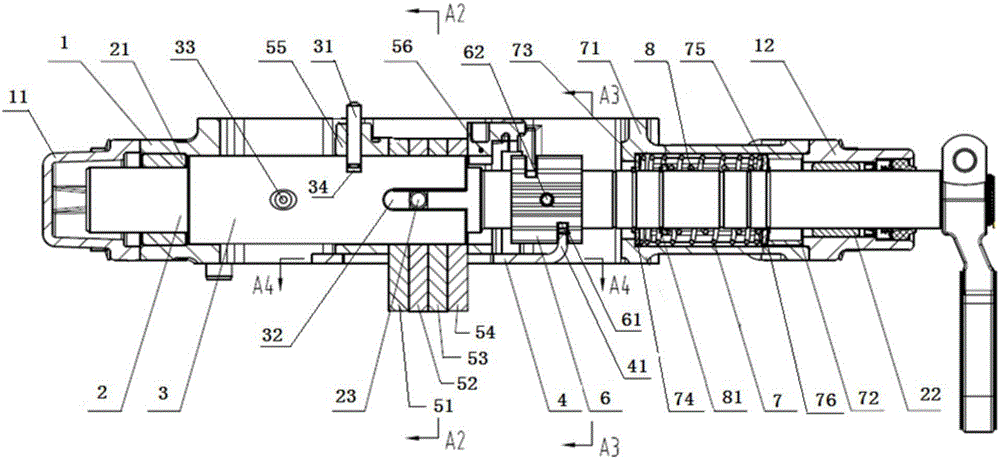

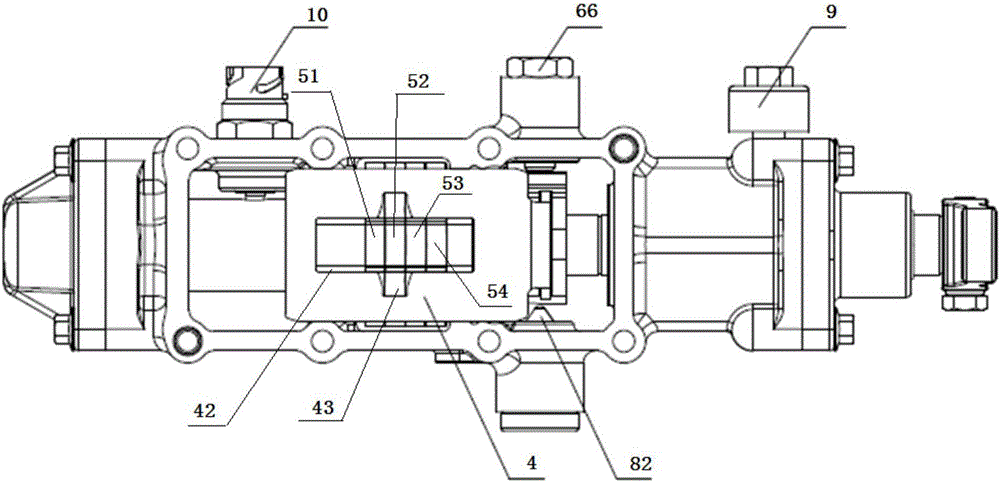

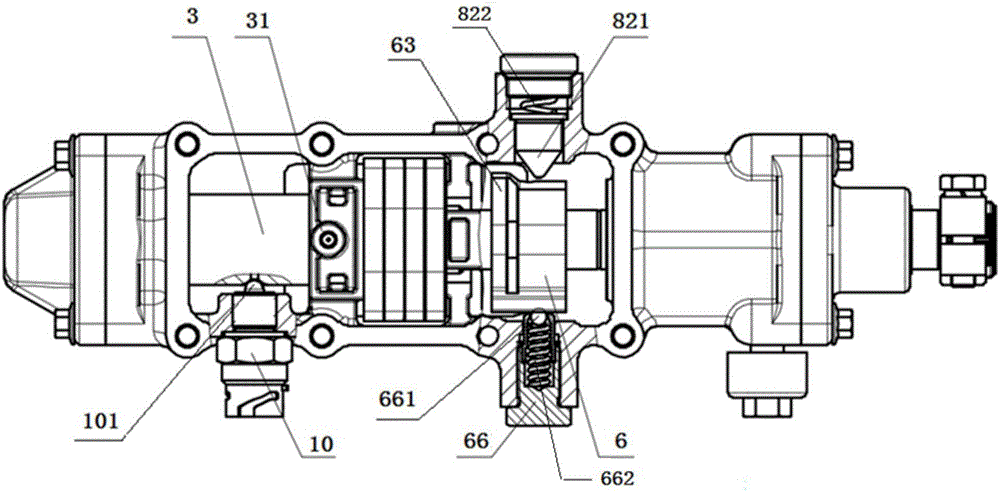

[0023] Such as figure 1 , 2 , 3, the passenger car transmission top cover assembly of the present invention includes a top cover housing 1, a rear end cover 11, a front end cover 12, a shift shaft 2, a left sliding bush 21, a right sliding bush 22, a Shaft pin 23, shift sleeve 3, cylindrical pin 31, interlock plate 4, four shift dials 51, 52, 53, 54, self-locking block 6, first return spring 7, baffle plate 71, Spacer 72, left limit spring retainer 73, left spring washer 74, right spring washer 75, right limit spring retainer 76, second return spring 8, spring washer 81, plunger 82, vent plug 9. Neutral switch 10.

[0024] The rear end cover 11 and the front end cover 12 are respectively fixed on the two ends of the top cover shell 1 . The gear shift sleeve 3 is installed in the top cover shell 1, and the axial opening long groove 32, the pit 33 and the circumferential groove 34 are processed on it; the cylindrical pin 31 is installed on the top cover shell 1, and its lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com