Hydrant seal structure with double sealing

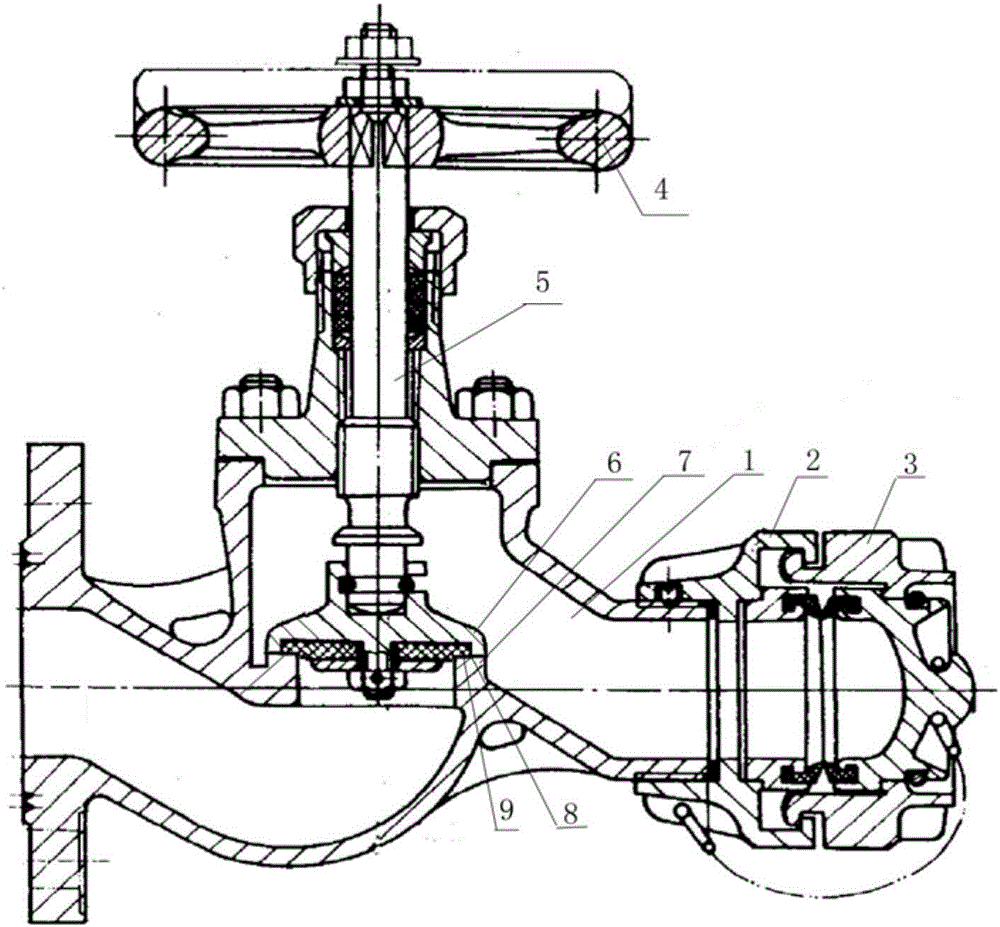

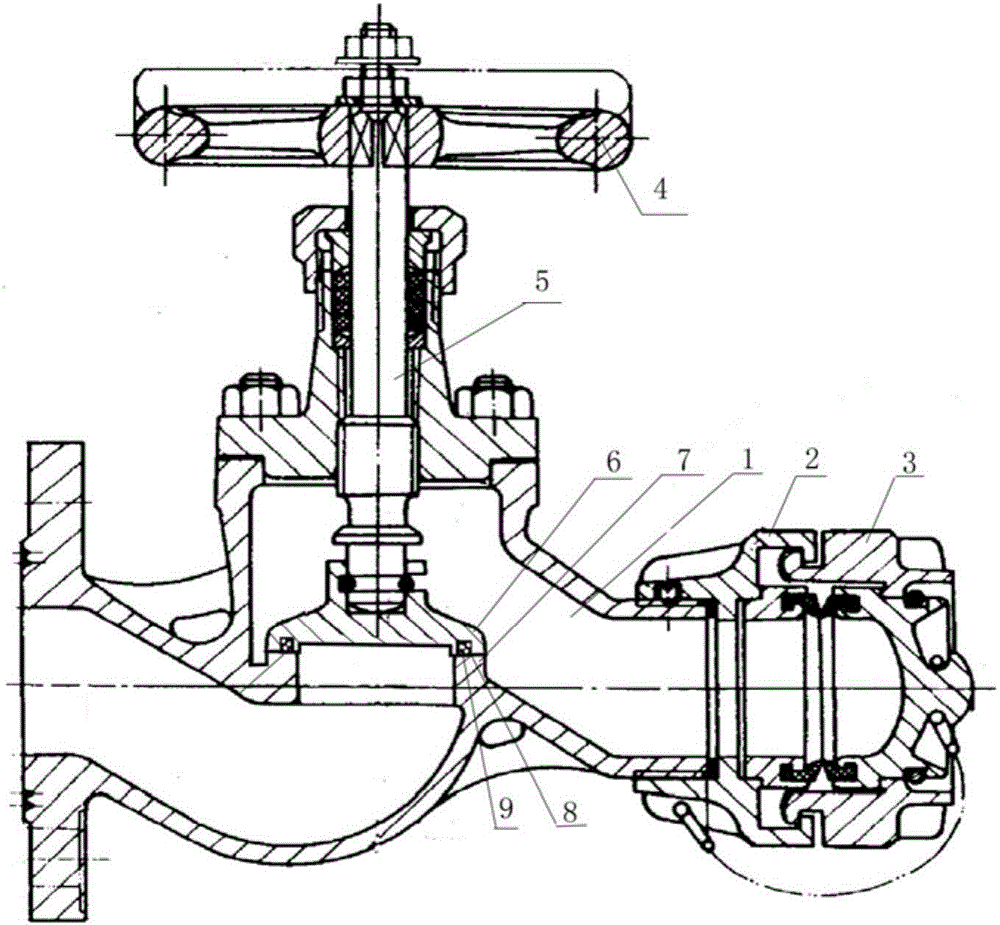

A technology of double sealing and sealing structure, applied in the direction of lift valves, engine components, mechanical equipment, etc., can solve the problems of easy-leaking soft-sealed fire hydrants, non-fire resistance, etc., to ensure integrity and safety, compact structure, mutual Change the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

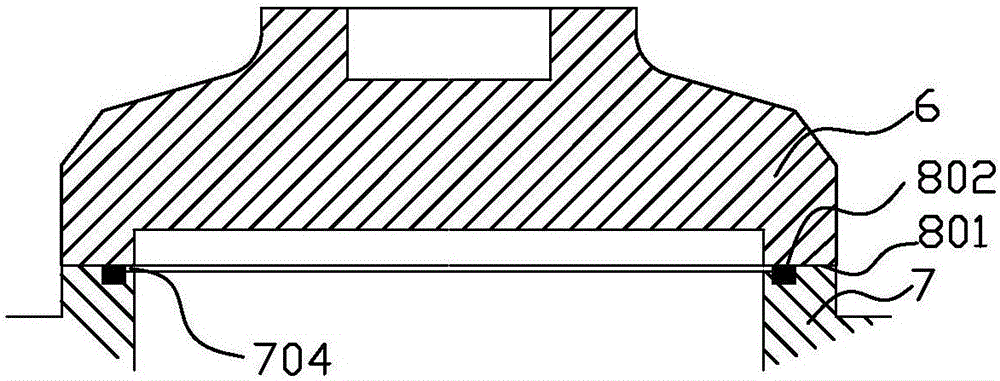

[0038] Embodiment 1: as image 3As shown, the hard seal pair 801 and the soft seal pair 802 are arranged on the plane contact surface formed by the metal valve disc 6 and the metal valve body 7 , and the elastic seal 9 constituting the soft seal pair 802 is arranged on the metal valve body 7 . The elastic sealing member 9 adopts a sealing ring, and the sealing ring is arranged inside the hard sealing pair 801 . When sealing, the metal valve body top between the inner wall of the metal valve body 7 and the sealing ring is not connected with the metal valve disc 6, that is, the metal valve body top between the inner wall of the metal valve body 7 and the sealing ring is the same as the metal valve body. There is a certain gap 704 between the disks 6; the top of the sealing ring is higher than the top of the metal valve body 7 before the fire hydrant is sealed, and the height of the sealing ring can be adjusted to change the sealing pressure distribution, so that the sealing pair...

Embodiment 2

[0039] Embodiment 2: as Figure 4 As shown, the hard seal pair 801 and the soft seal pair 802 are arranged on the plane contact surface formed by the metal valve disc 6 and the metal valve body 7 , and the elastic seal 9 constituting the soft seal pair 802 is arranged on the metal valve disc 6 . The elastic sealing member 9 adopts a gasket, and the gasket is arranged inside the hard sealing pair 801 . The top of the gasket is higher than the top of the metal valve disc 6 before the fire hydrant is sealed. Adjusting the height of the gasket can change the distribution of sealing pressure, so that the sealing pairs 801 and 802 can reach the specified sealing specific pressure.

Embodiment 3

[0040] Embodiment 3: as Figure 5 As shown, there is a tapered contact surface between the metal valve disc 6 and the metal valve body 7, and the soft sealing pair 802 is arranged on the tapered contact surface. The hard seal pair 801 is arranged on the plane contact surface of the metal valve disc 6 and the metal valve body 7 . The metal valve disc 6 has a valve disc conical structure 601, the lower end diameter of the valve disc conical structure 601 is smaller than the upper diameter (in an inverted conical structure), and the corresponding metal valve body 7 is provided with an upper port with a diameter larger than The valve body conical accommodation chamber 701 with the diameter of the lower opening is used to cooperate with the valve disc conical structure 601. The root of the valve disc conical structure 601 is provided with a valve disc contact plane, which corresponds to the valve body conical accommodation constituting the metal valve body 7. The top of the chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com