Riveting press with protection function

A technology of protective function and riveting machine, which is applied in the direction of mechanical equipment, engineering safety devices, etc., can solve the problems of low safety factor, non-conduction, conduction, etc., and achieve the effect of ensuring integrity and safety and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

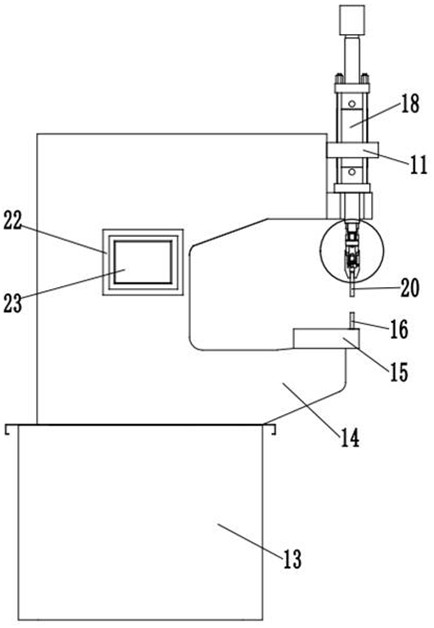

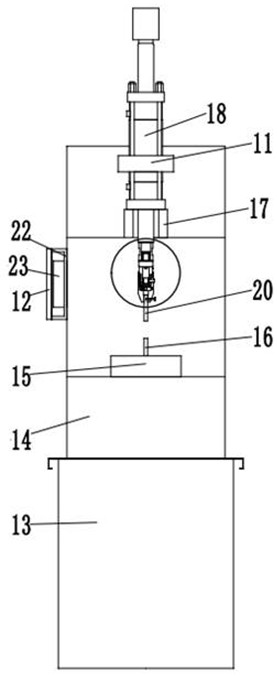

[0031] Embodiment: a riveting machine with a protective function, comprising an operation table 13, a pressure riveting structure is arranged on the operation table 13, and a control structure is arranged on the pressure riveting structure;

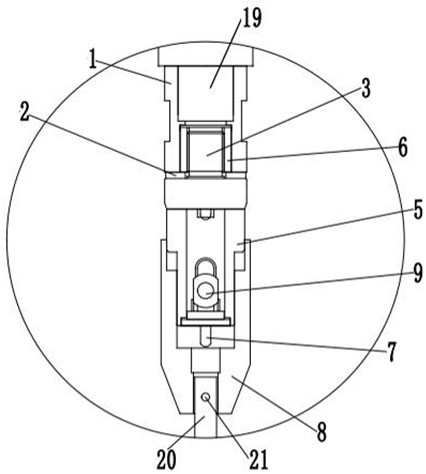

[0032] In the specific implementation process, the pressure riveting structure can preferably adopt the following structure, which includes: a work frame 14 , a work base 15 , a lower die 16 , a support frame 17 , a telescopic cylinder 18 and a protective part; the work frame 14 is installed on the operating table 13 . On the wall surface, the work frame 14 is installed on the upper wall surface of the operating table 13, the lower mold 16 is installed on the upper wall surface of the work seat 15, the support frame 17 is installed on the work frame 14, the telescopic cylinder 18 is installed on the upper wall surface of the support frame 17, and the support frame 17 is opened There is a through hole, the telescopic end of the telescopic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com