Milk powder reconstituting machine with ultrasonic automatic cleaning function

An automatic cleaning and ultrasonic technology, used in household appliances, kitchen appliances, beverage preparation devices, etc., can solve problems such as multiple gaps, secondary pollution, water leakage and liquid leakage, to ensure integrity and safety, avoid component damage, The effect of milk powder drinking safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

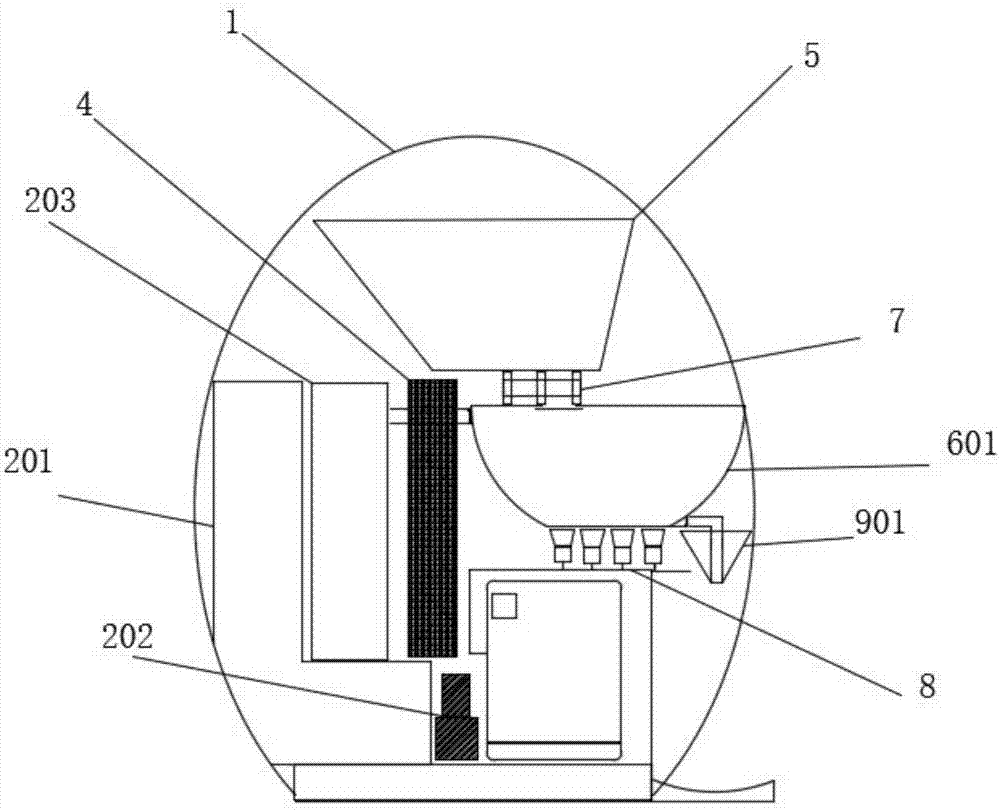

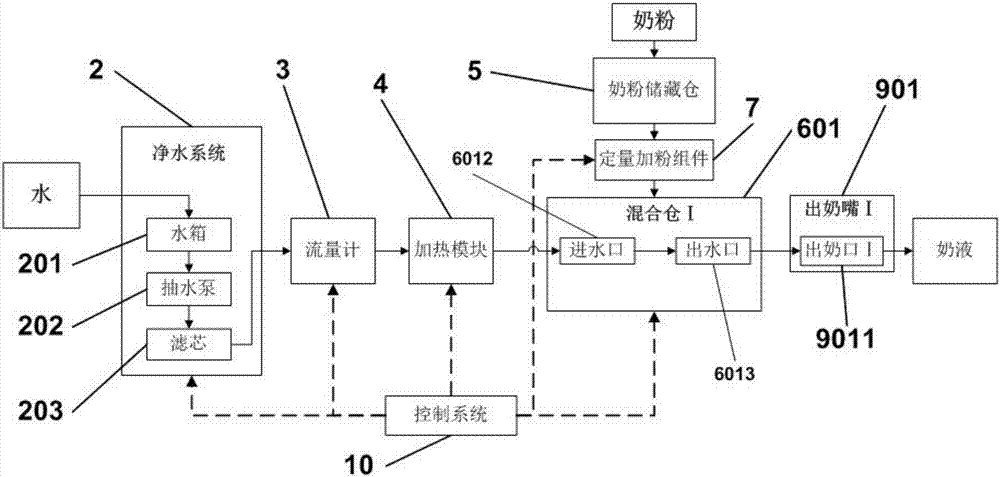

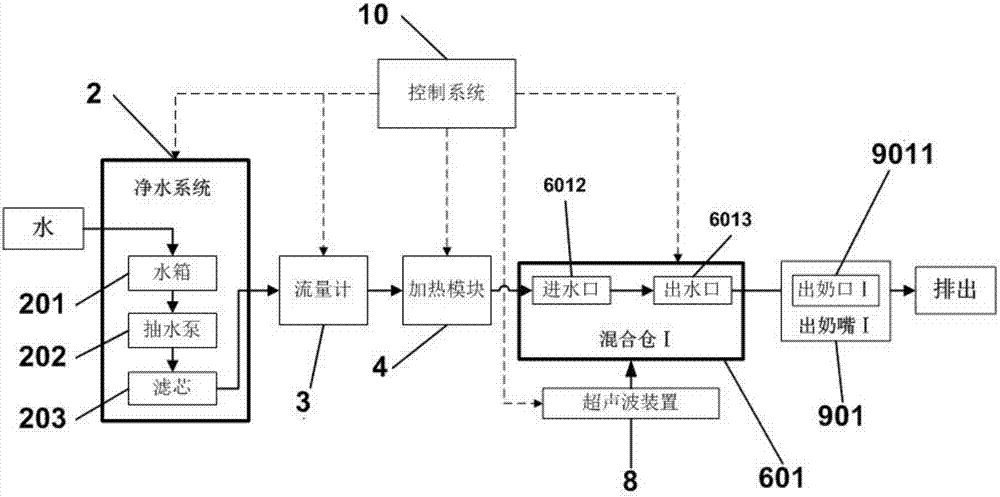

[0035] like Figure 1~6 As shown, a milk dispensing machine with ultrasonic automatic cleaning function includes a box body 1; a water purification system 2; a water tank 201; a water pump 202; a filter element 203; a flow meter 3; a heating module 4; a milk powder storage bin 5; a mixing bin Ⅰ601; powder inlet 6011; water inlet 6012; water outlet 6013; quantitative powder adding component 7; ultrasonic device 8; nipple I901; milk outlet I9011; control system 10.

[0036] The control system 10 is electrically connected to the water purification system 2, the flow meter 3, the heating module 4, the mixing chamber I 601, the quantitative powder addition component 7, and the ultrasonic device 8; the water purification system includes a water tank 201, a water pump 202, filter element 203; the water tank 201 is detachably installed in the box body 1, connected with the water pump 202, and provides water source for the filter element 203; the milk powder storage bin 5 is used for s...

Embodiment 2

[0039] like Figure 7-11 As shown, a preferred embodiment of the present invention is to provide a milk dispensing machine with an ultrasonic automatic cleaning function. This embodiment is basically similar to Embodiment 1, the difference lies in the following aspects:

[0040] (1) The raw material of the mixing bin II602 is food-grade stainless steel with a circular cross section. The top of the mixing bin II602 is provided with a powder inlet 6021 corresponding to the quantitative powder adding component 7; the bin of the mixing bin II602 The upper part of one side of the wall is provided with a first water inlet 6022, and the lower part of the other side is provided with said water outlet 6023 and a second water inlet 6024; One-way automatic valve, the second water inlet 6024 is connected with the booster pump 6025, and the flow meter 3 and the heating module 4 are connected between the first water inlet 6022 and the filter element 203; The first water inlet 6022 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com