Composite structure sealing plug for pipeline

A composite structure and sealing plug technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of easy deformation, inconvenient loading and unloading, large amount of rubber, etc., to avoid wear and scratches, Ease of installation and disassembly, and the effect of saving energy and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The composite structure sealing plug for pipelines of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

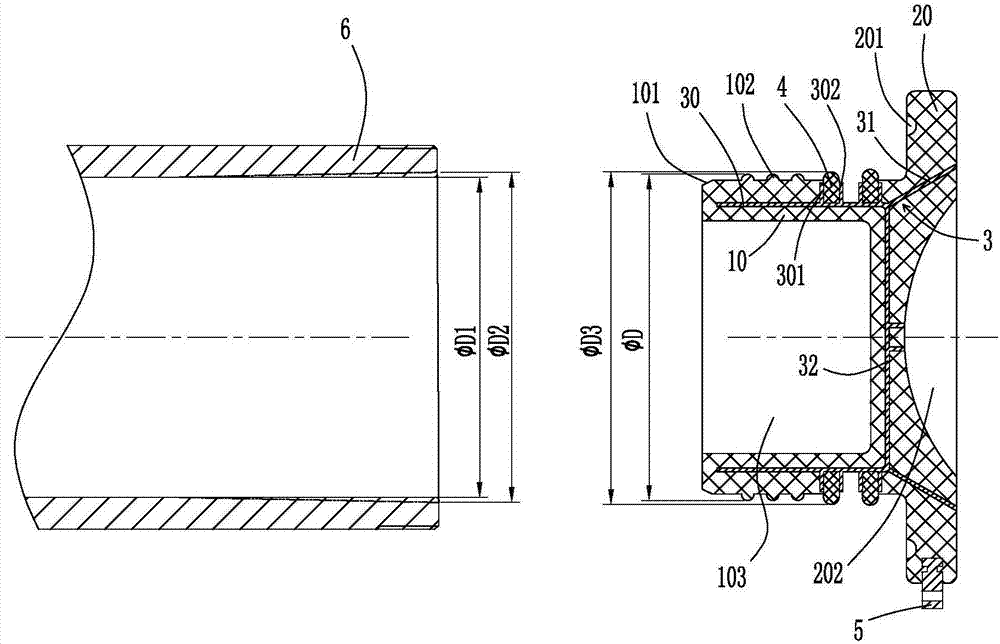

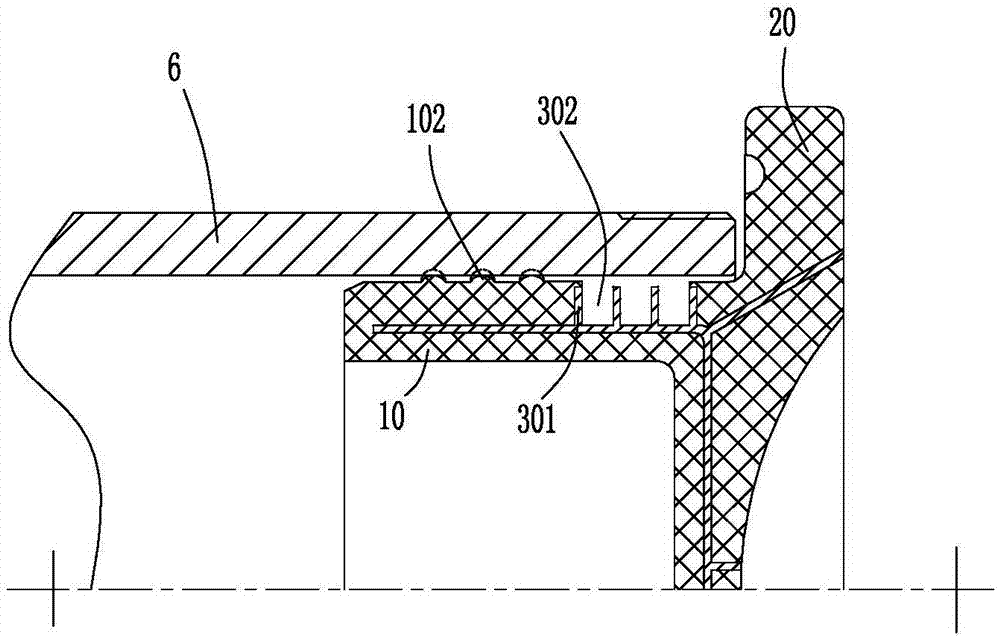

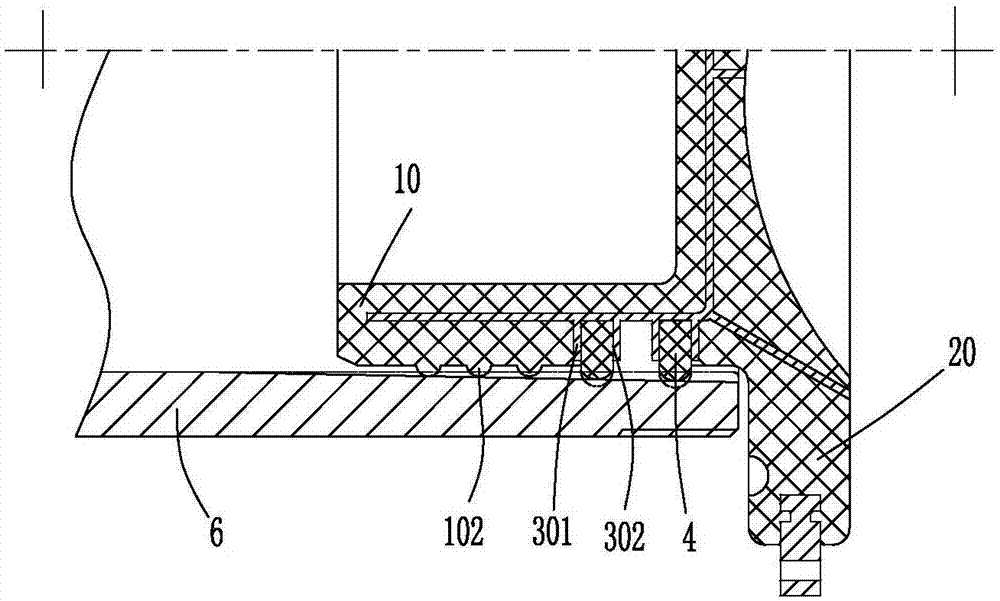

[0026] For the convenience of description, the "left" and "right" mentioned below are consistent with the left and right directions of the drawings themselves. Such as figure 1 As shown, in this specific embodiment, the composite structure sealing plug for pipelines of the present invention includes a rubber sealing part 10, a rubber end cap part 20, and a metal skeleton 3 for supporting the rubber sealing part 10 and the rubber end cap part 20, The rubber sealing part 10 and the rubber end cover part 20 are integrated, and the outer peripheral wall of the rubber sealing part 10 is provided with several annular flanges 102 matching with the pipe ports, and the metal skeleton 3 is placed on the rubber sealing part 10 and the rubber end cover part. 20, the left end of the rubber sealing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com