Piezoelectric balance calibration loading sleeve

A balance calibration and loading sleeve technology, which is applied in the direction of measuring devices, instruments, aerodynamic tests, etc., can solve problems such as the inability to meet the repeatability accuracy of piezoelectric balance calibration, the inability to ensure the repetition of loading point positions, and the difficulty of small load calibration. To achieve the effect of changing the calibration balance of different loads, facilitating the change of calibration balances of different loads, and the effect of convenient and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

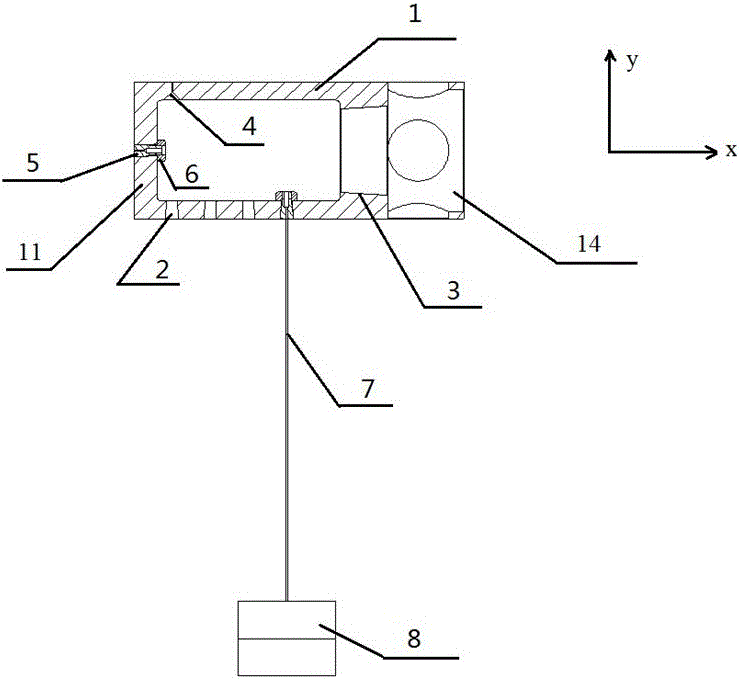

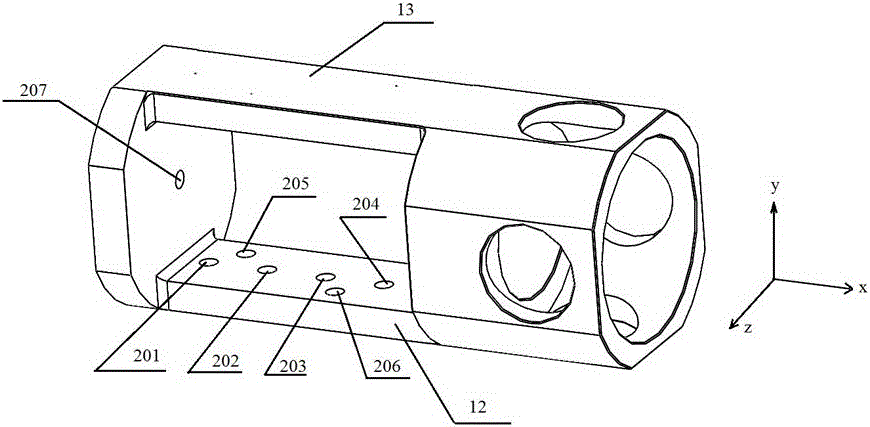

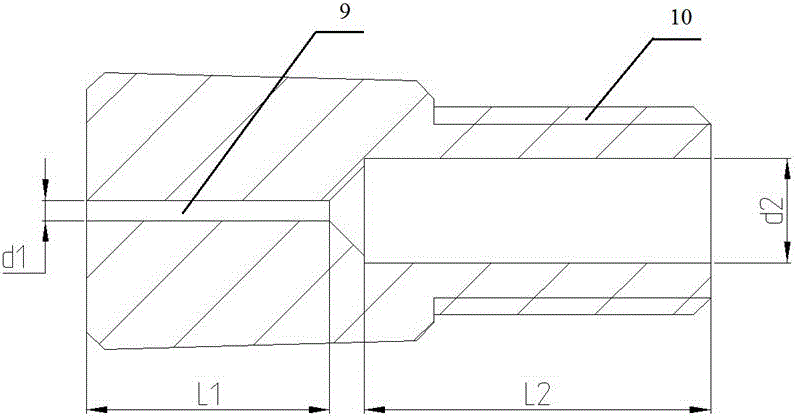

[0043] When the piezoelectric balance is calibrated, the piezoelectric balance is first fixedly installed on the calibration seat, and then the main body of the loading sleeve 1 is preliminarily installed on the piezoelectric balance. Change the posture of the main body 1 of the loading sleeve, measure and adjust the relative position relationship with the piezoelectric balance through the measurement plane on the main body 1 of the loading sleeve, and then fix the connection between the main body 1 of the loading sleeve and the piezoelectric balance, and ensure that the calibration of the piezoelectric balance The relative position does not change during the process. One end of the loading wire 7 is installed on the loading nail 5 through the wire hole 9 , and the other end is connected to the standard weight 8 . The loading nail 5 is installed on the loading line hole 2 of the loading sleeve main body 1, and the loading nail 5 is fixed on the loading sleeve main body 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com