Method for automatically recognizing maximum modal component

A technology of automatic identification and maximum mode, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of large waste of human resources, low efficiency, occupation of computing resources, etc., to reduce labor intensity and improve efficiency. , the effect of reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

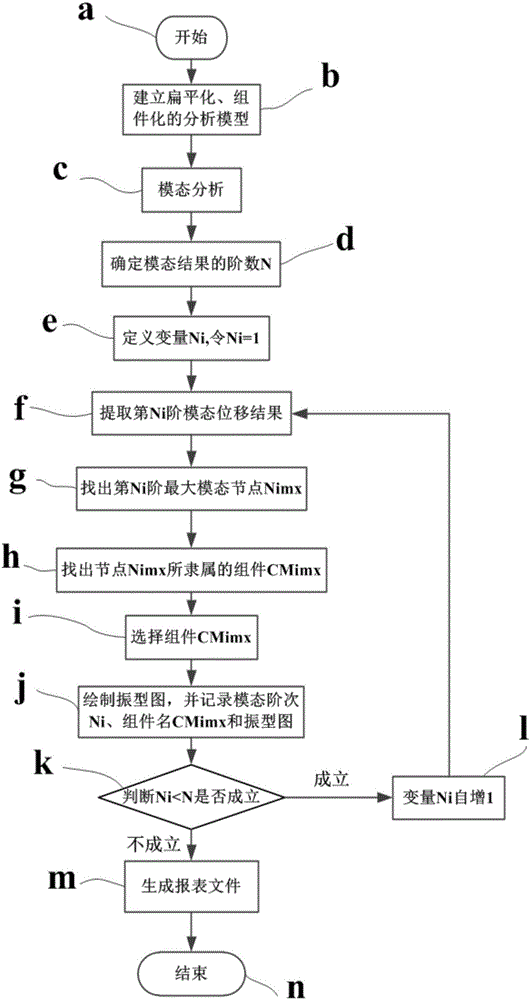

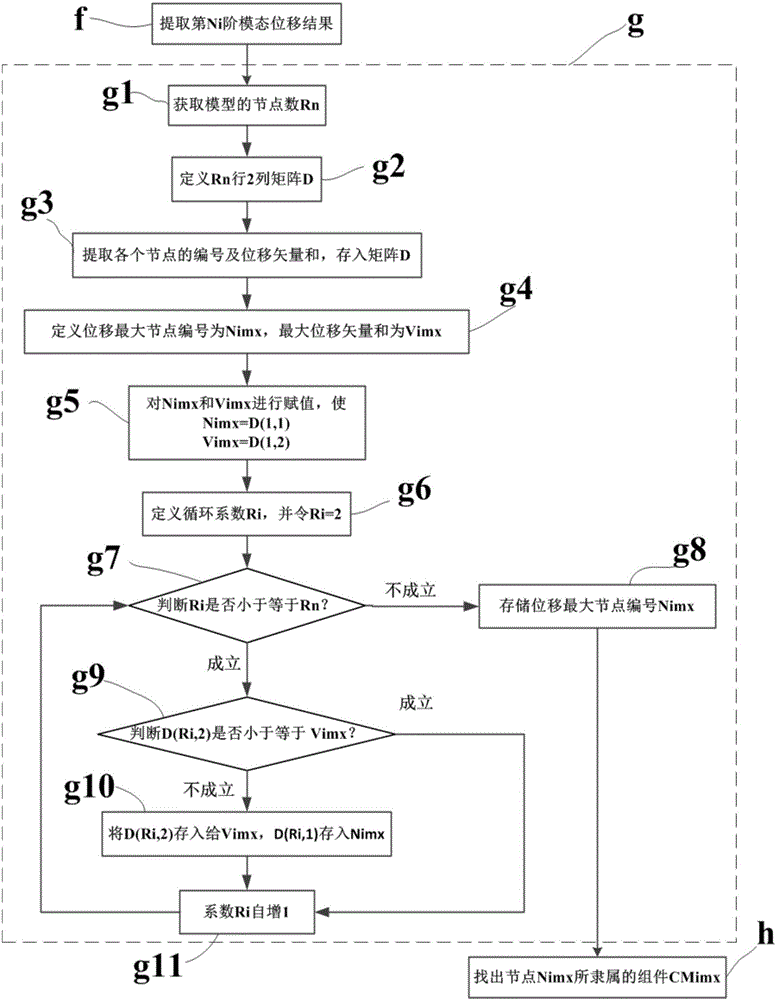

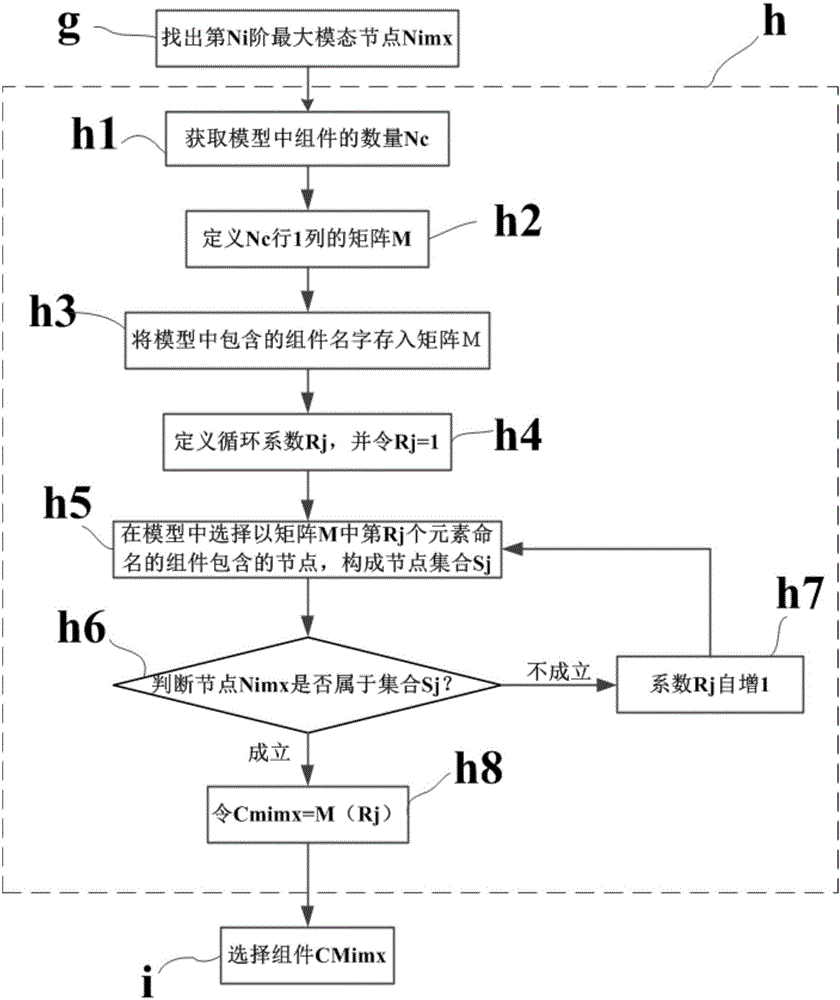

[0019] refer to Figure 1-Figure 4 . The present invention can be realized with reference to the following examples. According to the invention, the invention requires the determination of the maximum modal displacement node. The maximum modal displacement node represents the location of the greatest deformation in the mode shape. The process of determining the maximum mode displacement node in the present invention includes: defining a matrix of Rn×2.

[0020] In the process of finite element modal analysis of modular electronic equipment, a flat and componentized analysis model is established, and the division standard is selected according to the requirements of structural modularization and functional independence to divide the analysis model into multiple parallel and independent components , to determine the maximum modal displacement node and its component. First, define a matrix of Rn×2, in which column 1 stores the numbers of all nodes in the model, and column 2 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com