Three-phase electric rectification circuit and three-phase electric rectification circuit time sequence control method

A technology of rectification circuit and three-phase alternating current, applied in the direction of converting AC power input into DC power output, electrical components, output power conversion devices, etc., can solve problems such as switch damage, avoid switch damage, improve reliability, Avoid the effect of inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

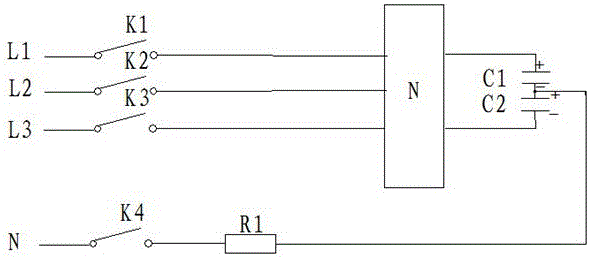

[0019] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

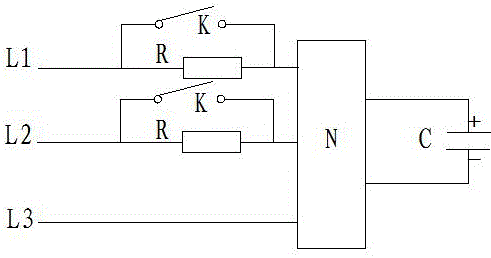

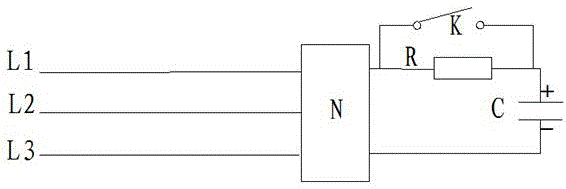

[0020] The purpose of this application is to propose a three-phase electric rectification circuit to solve the problem that the voltage at both ends of the electrolytic capacitor after charging will be lower than the three-phase electric rectification voltage due to the voltage division effect of the current-limiting resistor in the existing three-phase electric rectification circuit. When the circuit switch is closed, a large inrush current will be generated to cause damage to the switch.

[0021] Such as image 3 As shown, the present application proposes a three-phase rectification circuit, including a three-phase AC input, a rectifier bridge N and an electrolytic capacitor; the three-phase AC output includes a first-phase AC input L1, a second-phase AC input L2 and a third-phase AC Input L3; an electrolytic capaci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap