Mobile phone shell and manufacturing method thereof

A mobile phone shell and mobile phone technology, which is applied to the structure of telephones, other household appliances, household components, etc., can solve the problems of easy falling off of the middle plate, and achieve the effect of easy falling off, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

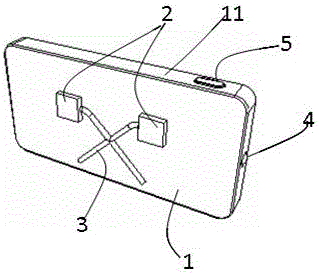

[0040] like figure 1 As shown, a mobile phone case of the present invention includes a mobile phone housing for accommodating internal components of the mobile phone. Two support frame connection ends 2 are arranged on the back of the case, and an X-shaped support frame 3 is movably connected to the connection end 2. The X-shaped support frame has a first end and a second end, wherein the first end is pivotally connected to the two support frame connection ends 2 on the back of the shell, and the second end is a free end; the X-shaped support frame 3 is formed with the shell The angle is 0 degree, at this time, the support frame 3 is attached to the shell, and the support frame 3 does not work. At the position corresponding to the X-shaped support frame 3 on the back of the mobile phone case, there is an X-shaped groove 31, the depth of the groove 31 is equal to the thickness of the X-shaped support frame, and the X-shaped support frame can be connected with the groove. 31 fi...

Embodiment 2

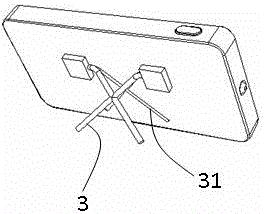

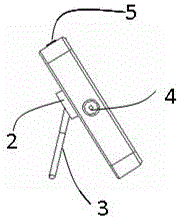

[0042] like figure 2 , 3 As shown, a new mobile phone case of the present invention includes a mobile phone case and a middle plate (not shown in the figure), and two support frame connection ends 2 are arranged on the back of the case, and an X-shaped support frame is movably connected to the connection end 2 3. The X-shaped support frame 3 has a first end and a second end, wherein the first end is pivotally connected to the two support frame connection ends 2 on the back of the shell, and the second end is a free end; the X-shaped support frame The angle formed with the shell is 30 degrees, and at this moment, the support frame 3 can support the mobile phone on the table. At the position corresponding to the X-shaped support frame 3 on the back of the mobile phone case, there is an X-shaped groove 31 whose depth is smaller than the thickness of the X-shaped support frame. When supporting, the X-shaped support frame 3 can be partially attached to the groove 31 when it is p...

Embodiment 3

[0044] A method for preparing a mobile phone case, comprising the following steps:

[0045] Step 1: Die-cast the metal material into the prototype of the medium plate;

[0046] Step 2: Carry out CNC machining on the prototype of the middle plate, and mill out the area for placing various components inside the mobile phone to form the middle plate;

[0047] Step 3: Die-cast the metal material into the shell prototype;

[0048] Step 4: Carry out CNC machining on the prototype of the shell, mill out the lamp hole, switch hole, volume control hole, power button hole, the interface that is movably connected with the support frame, and the groove that matches the shape of the support frame to form the shell;

[0049] Step 5: Connect the middle plate and the shell as a whole by laser welding;

[0050] Step 6: T treatment the mobile phone case welded in step 5;

[0051] Step 7: Carry out nano-injection molding on the T-treated mobile phone case to obtain a mobile phone case;

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com