Working medium for heat cycle, and heat cycle system

A technology of working medium and circulation system, applied in irreversible cycle compression machines, heat exchange materials, lighting and heating equipment, etc., can solve problems such as the greenhouse effect, and achieve the effect of excellent safety and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0196] The present invention will be described in detail through examples below, but the present invention is not limited by the following description.

[0197] [combustibility evaluation]

[0198] The evaluation of flammability was implemented using the equipment prescribed|regulated by ASTM E-681.

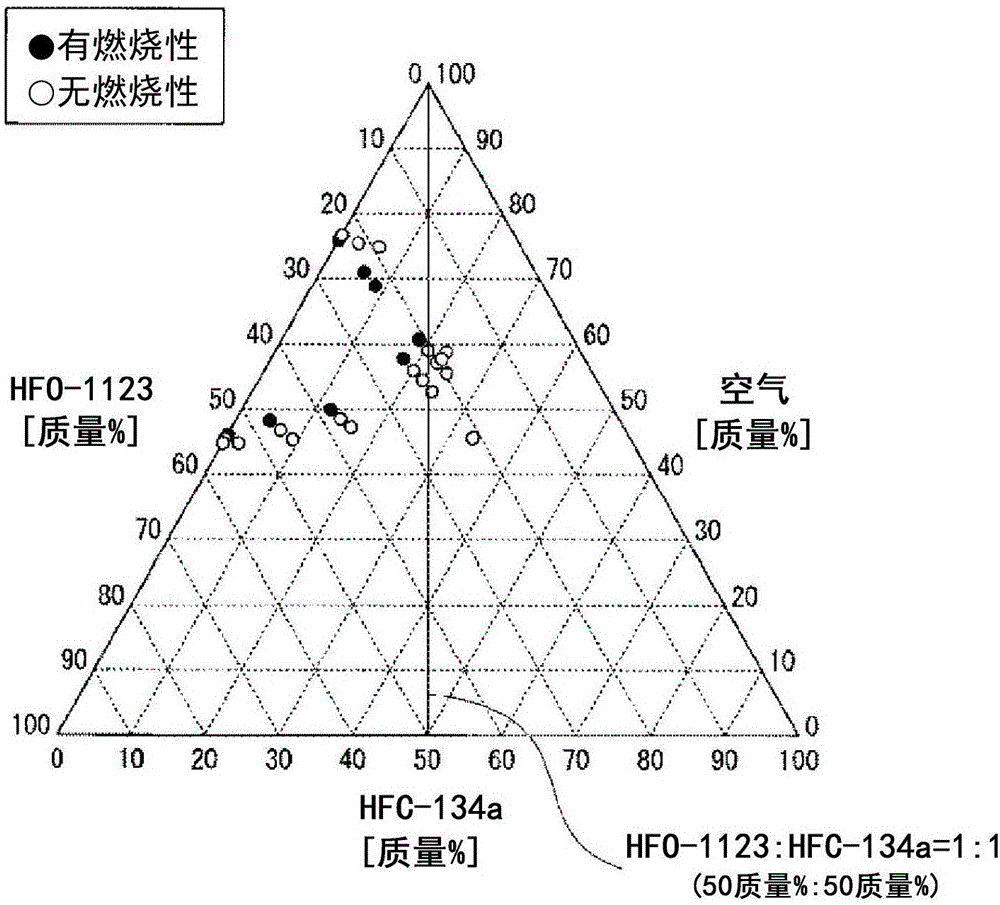

[0199] After vacuum-exhausting the flask with an inner volume of 12 liters installed in a thermostat controlled at a temperature of 25°C, the pressure was adjusted to atmospheric pressure. image 3 or Figure 4 Seal the working medium and air of each concentration in the graph. Thereafter, in the gas phase in the vicinity of the center in the flask, it was discharged and burned at 15 kV and 30 mA for 0.4 seconds, and then the expansion of the flame was visually confirmed. When the upward flame spread angle exceeds 90°, it is judged to be flammable, and when it is less than 90°, it is judged to be non-combustible.

example 1

[0201] HFO-1123 and HFC-134a were mixed in a predetermined ratio, and the combustibility of the two-component system working medium was evaluated. The relationship between the ratio of HFO-1123, HFC-134a and air in the gas phase in the flask and the combustibility is shown in image 3 .

[0202] Such as image 3 As shown, it can be seen that the ratio of HFO-1123 in the working medium in the gas phase in the flask is 50% by mass or less (compared to image 3 The working medium on the right side of the straight line representing HFO-1123:HFC-134a=1:1) does not have a combustible range ("combustible" range). In other words, it can be seen that a working medium in which the proportion of HFO-1123 in the working medium in the gas phase is 50% by mass or less suppresses combustibility regardless of the concentration mixed with air.

example 2

[0204] HFO-1123 and HFC-125 were mixed in a predetermined ratio, and the combustibility of the working medium of the two-component system was evaluated. The relationship between the ratio of HFO-1123, HFC-125 and air in the gas phase in the flask and the presence or absence of combustibility is shown in Figure 4 .

[0205] Such as Figure 4 As shown, it can be seen that the ratio of HFO-1123 in the working medium in the gas phase in the flask is 50% by mass or less (compared to Figure 4 The working medium on the right side of the straight line representing HFO-1123:HFC-125=1:1) does not have a combustible range ("combustible" range). In other words, it can be seen that a working medium in which the ratio of HFO-1123 in the working medium in the gas phase is 50% by mass or less suppresses combustibility regardless of the concentration mixed with air.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap