Electric motor with brake

A technology of electric motors and brakes, which is applied in the direction of motor generator control, electromechanical brake control, electric components, etc., to avoid cost increase and achieve the effect of braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

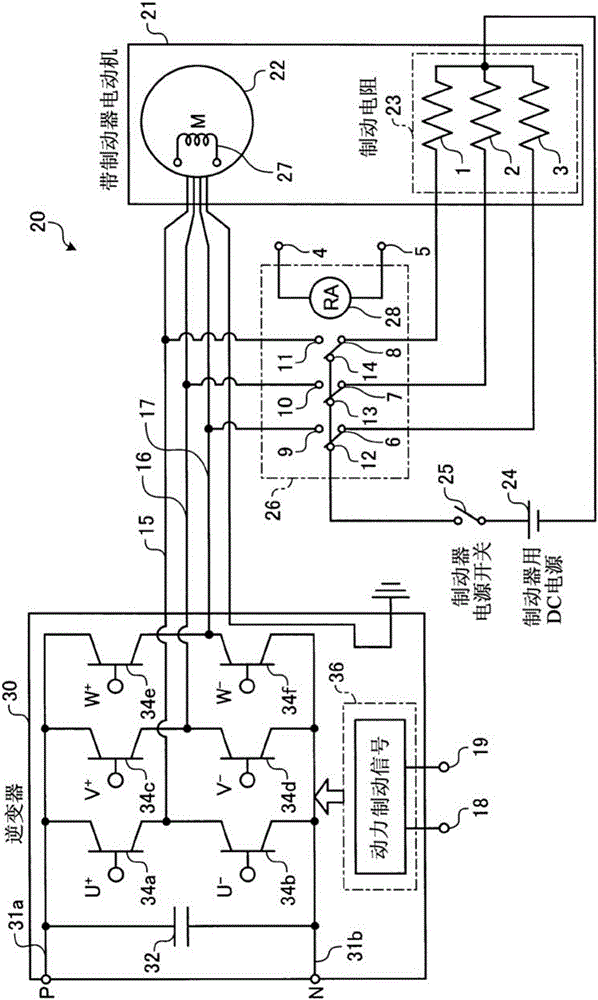

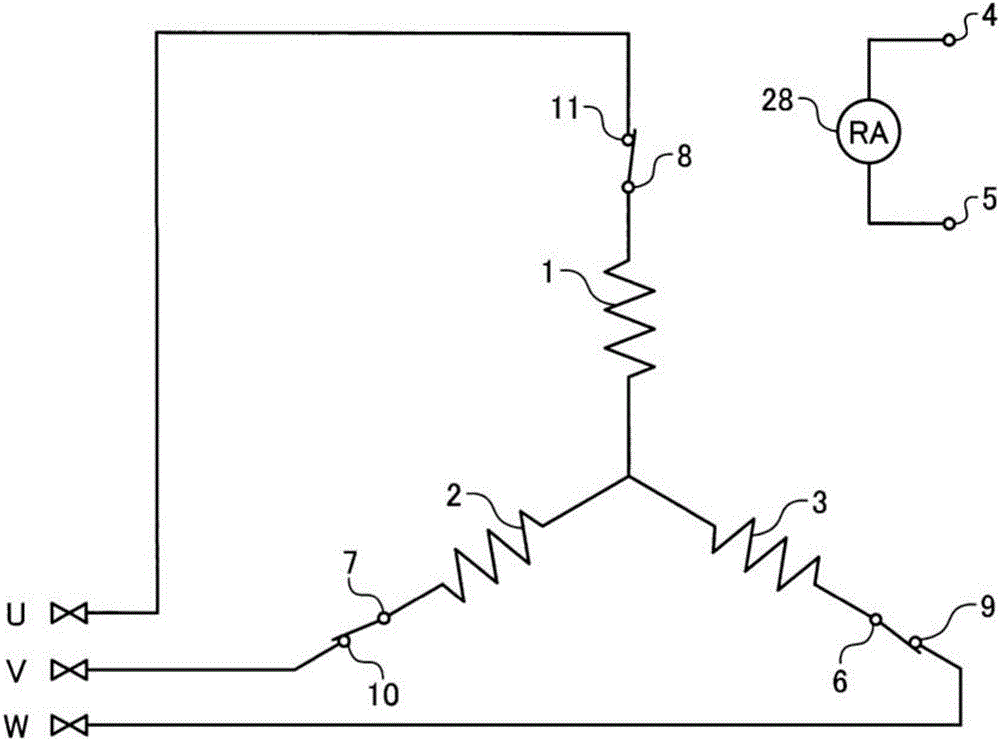

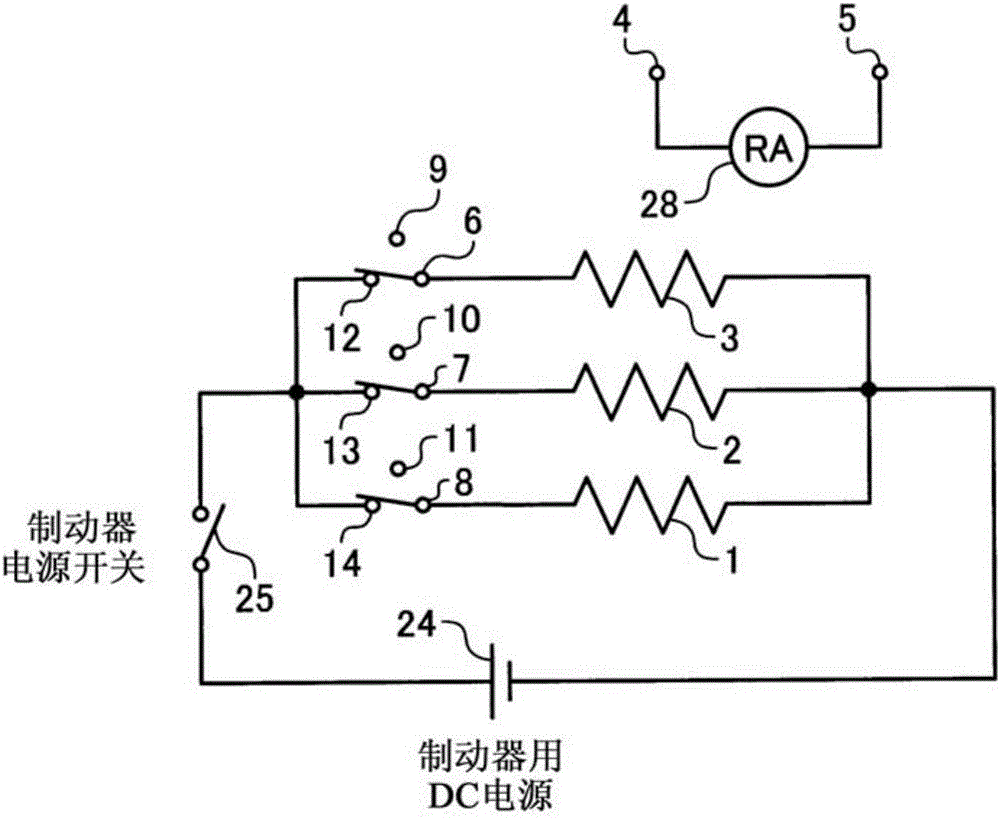

[0015] A motor with a brake according to an embodiment of the present invention will be described below with reference to the drawings. In addition, this invention is not limited to embodiment shown below.

[0016] figure 1 The diagram showing the configuration of a motor system including the motor with brake according to the embodiment shows a configuration example in the case where the motor system is driven by an inverter. Such as figure 1 As shown, the motor system 20 according to the embodiment includes: a motor with brake 21 including a motor 22 and a braking resistor 23; a DC power supply 24 for the brake; a brake power switch 25; and a relay element 26. The motor system 20 is configured as , the motor 22 is driven by the inverter 30 .

[0017] The inverter 30 is a known circuit structure, such as figure 1 As shown in FIG. + ) and the switching element 34b (U - ) are connected in series, and three of these series circuits are connected in parallel to form a UVW ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com