Split-type automatic sprinkler

An automatic spraying and separation technology, which is applied in the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of affecting the life of the device and its life, and achieve the effect of improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0024] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, each specific embodiment and each technical feature described below can be combined arbitrarily to form a new specific embodiment.

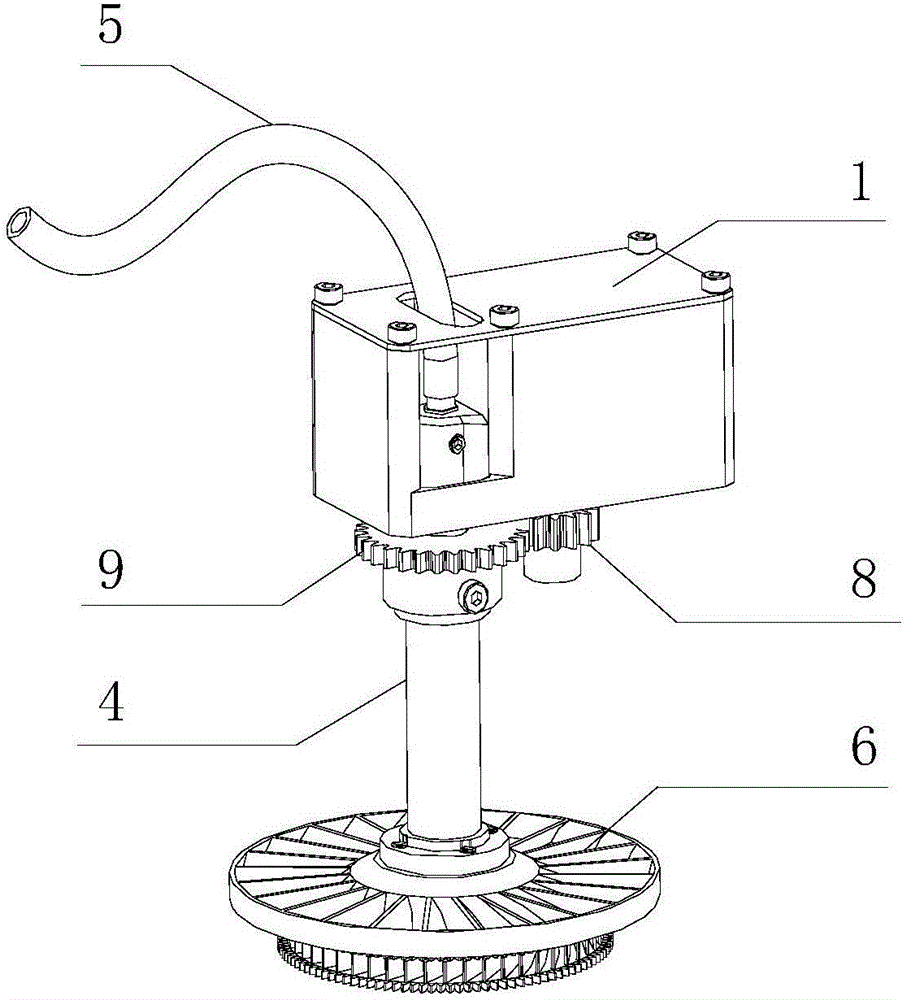

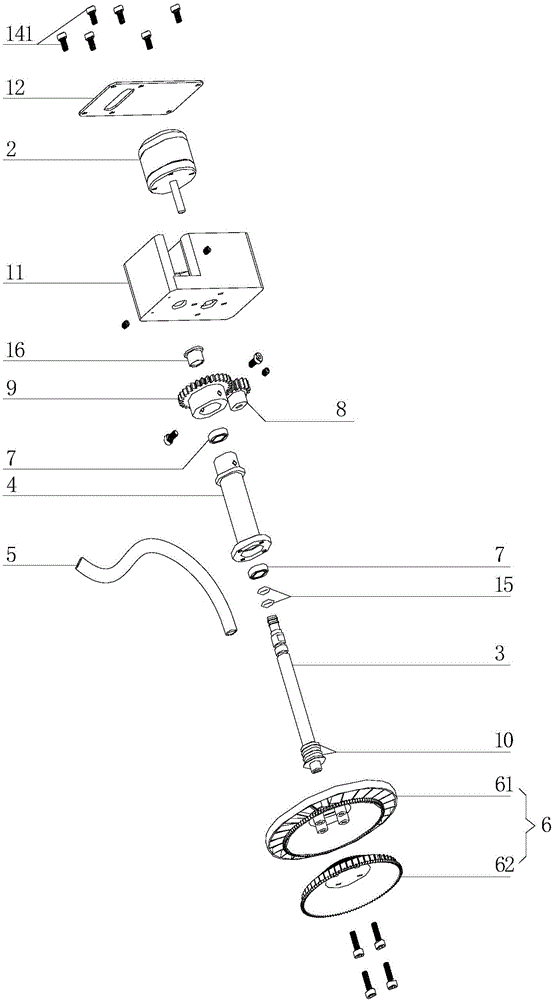

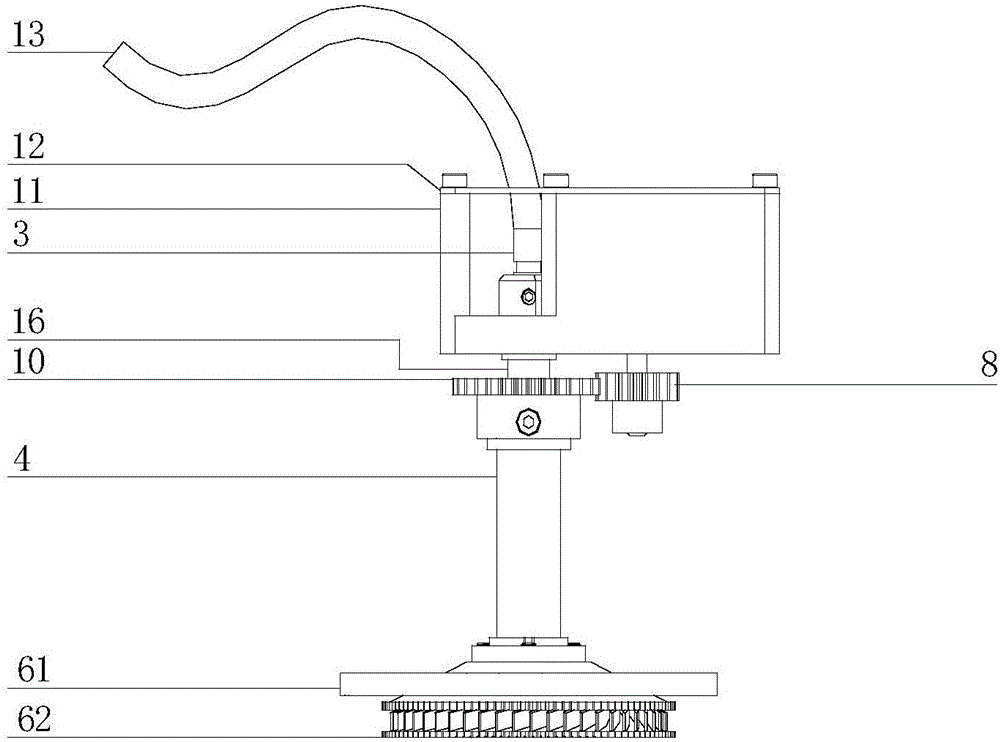

[0025] see figure 1 and figure 2 , the present invention discloses a separate automatic spraying device, including a chassis 1, a motor 2, a hollow inner column 3, a hollow outer column 4, a silicone tube 5 and a spray plate 6. For convenience of description, the figure 1 The orientation is described for reference.

[0026] read on figure 1 and figure 2 , the chassis 1 is rectangular, including a bottom shell 11 and a box cover 12, the box cover 12 is fixed on the bottom shell 11 by several first screws 141, forming the chassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com