Device and process for mixing tea leaves and dried flowers

A dried flower and tea technology, which is applied in the field of tea and dried flower mixing devices, can solve the problems of low production efficiency, easy damage to the integrity of dried flowers, and the inability to produce large-scale production, and achieve simple structure, ensure the integrity of the shape, and improve the rhythm balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

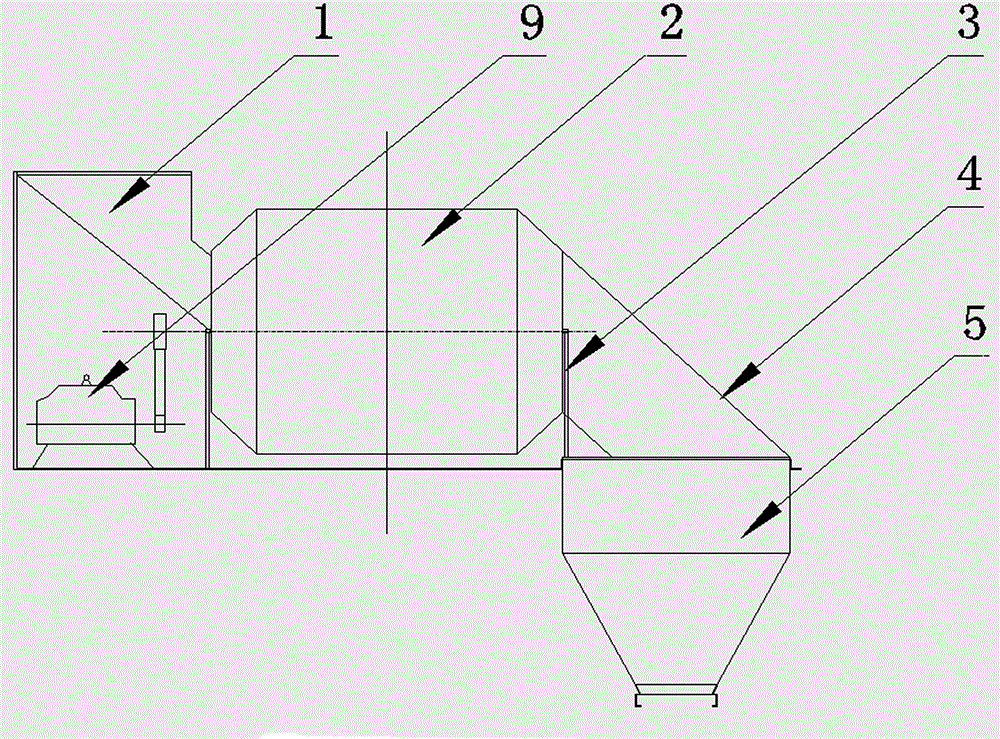

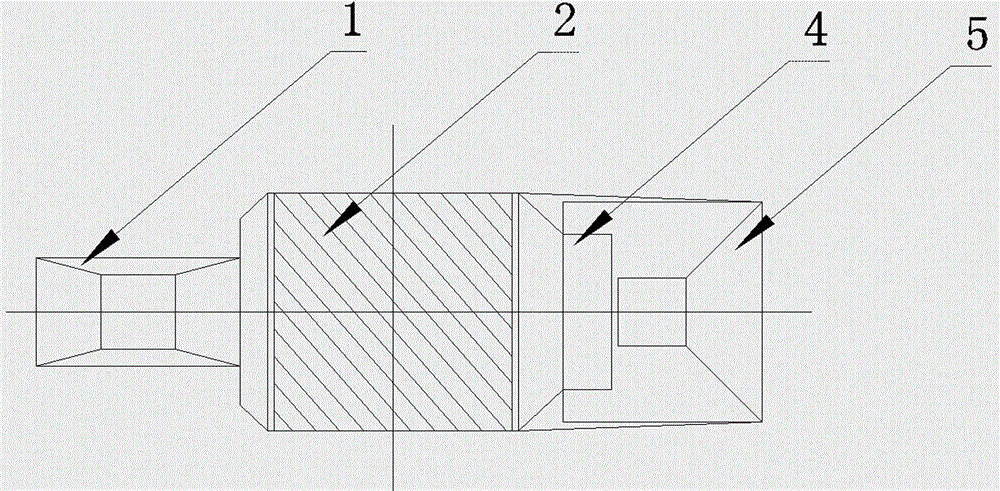

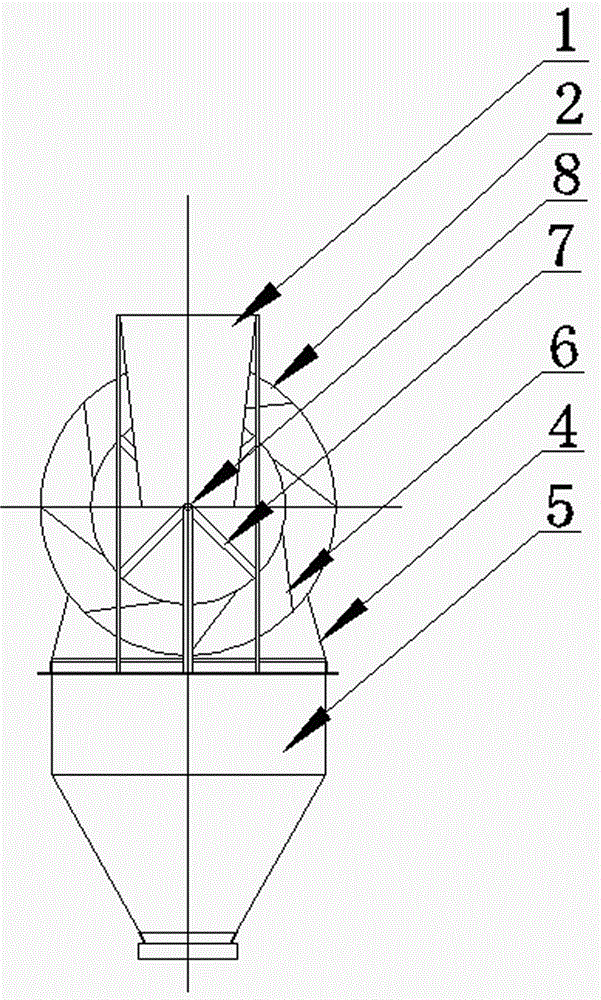

Image

Examples

example

[0027] The following is an example of adding dried jasmine flowers to traditional jasmine tea to illustrate the process of adding dried jasmine flowers to traditional jasmine tea using a mixing device for tea leaves and dried flowers. The mixing technology of dried flower comprises the steps:

[0028] (1) Production of dried jasmine flowers. From July to August every year, jasmine flowers picked in the afternoon on a sunny day are selected. When the flowers are in bud, they are dehydrated to make dried jasmine flowers. The finished dried jasmine flowers should be white in color and plump in shape.

[0029] (2) Dried flowers should be visually sorted before use to remove sundries and unattractive flowers. Good dried flowers should be white, plump, complete, and uniform. After sorting, pack them for later use.

[0030] (3) The tea leaves are blended and sanitized on the production line and flowed to the weighing place. According to the preset weight, 28kg of tea leaves are weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com