Machining method for guaranteeing shape completeness of air inlet and air outlet side circular arcs of blade

A technology of intake and exhaust edges and processing methods, which is applied in the field of parts processing, can solve the problems of incomplete arcs of the intake and exhaust edges of the blade profile, over-polishing, etc., and achieve the goal of improving the processing pass rate and eliminating the processing over-polishing phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

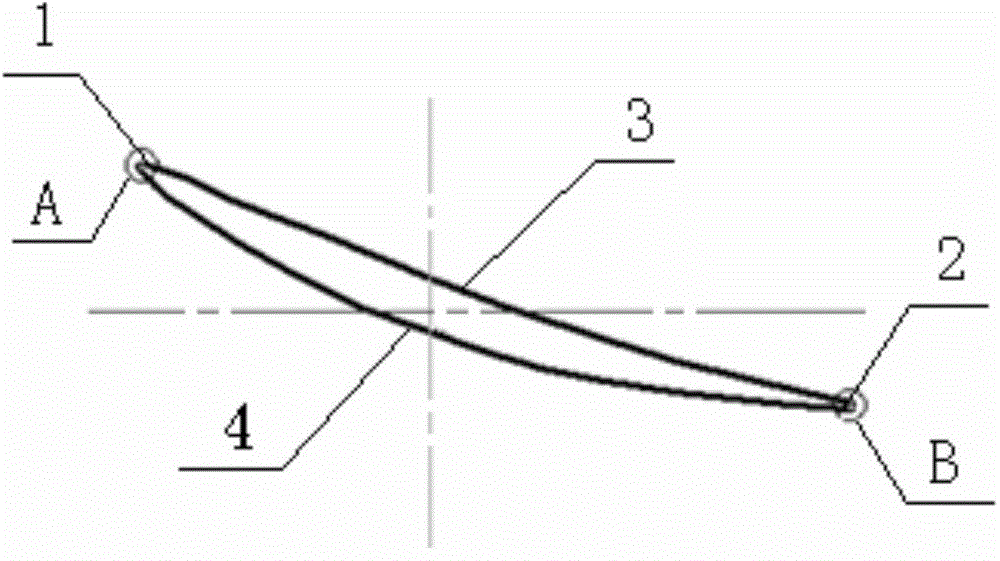

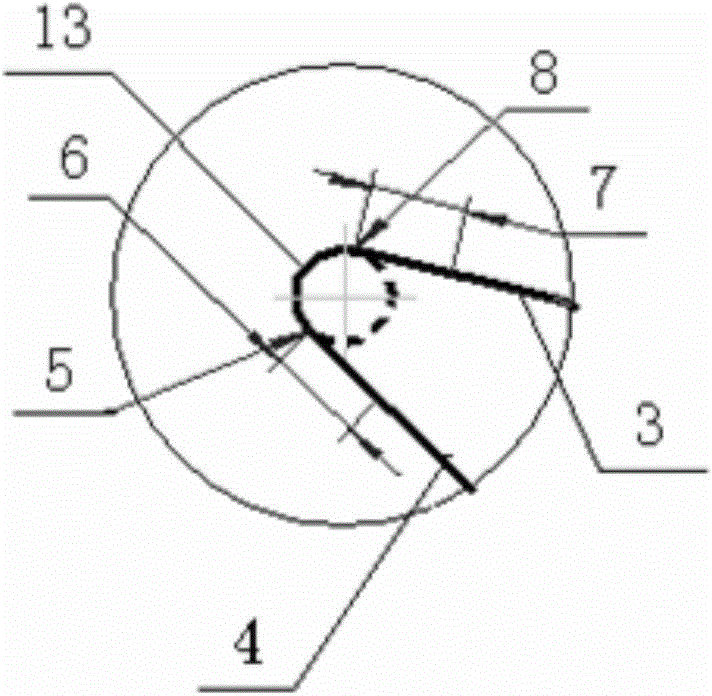

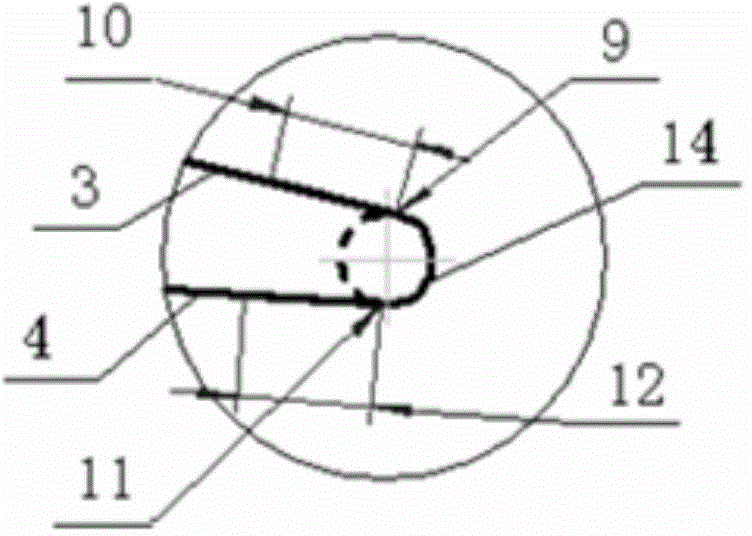

[0020] like Figure 1~4 As shown, a processing method to ensure the integrity of the arc shape of the inlet and exhaust edges of the blade. The machining of the blade surface adopts the longitudinal numerical control milling method, and the blade surface is divided into the arc area of the inlet edge 1 and the arc of the exhaust edge. Area 2, blade basin profile area 3 and blade back profile area 4 four processing areas, air inlet edge arc area 1 includes inlet edge arc 13, inlet edge arc and blade basin profile curve tangent point 8 The section 7 extending 3 mm outside the arc of the intake side and the section 6 extending 3 mm from the point of tangency between the arc of the intake side and the blade back surface curve 5, the arc of the exhaust side 2 includes the exhaust Edge arc 14, point of tangency between the arc of the exhaust edge and the profile curve of the blade basin 9 extends 3 mm to the arc of the exhaust edge 10 and point of tangency between the arc of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com