Central circulation tube evaporator

A central circulation tube and evaporator technology, applied in vertical tube evaporators, evaporator accessories, evaporation, etc., can solve problems such as low convective boiling heat transfer coefficient, reduced effective temperature difference, easy scaling, etc., to achieve Improve convective heat transfer coefficient and convective diffusion ability, improve convective heat transfer coefficient, and not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

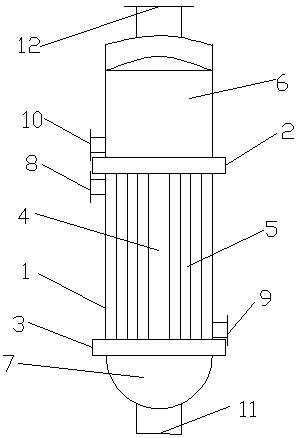

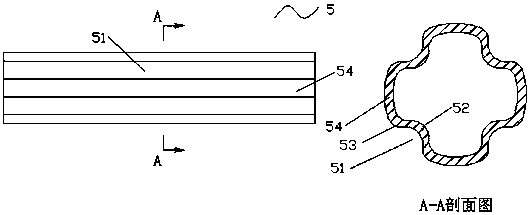

[0025] like figure 1 and figure 2 As shown in the figure, a central circulating tube evaporator includes a cylinder body 1, an upper tube sheet 2 and a lower tube sheet 3 welded in the cylinder body 1 and vertically connected to the cylinder body 1, and the upper tube sheet 2 and the lower tube sheet 3 are connected between There is a central circulation pipe 4 coinciding with the axis of the cylinder body 1 and a group of boiling pipes 5 arranged around the central circulation pipe 4. The upper tube plate 2 is connected with the upper head to form a steam chamber cavity 6, and the lower tube plate 3 is connected to the lower seal. The head forms the lower tube box 7, the cylinder body 1 is connected to the shell side primary steam inlet pipe 8 near the upper tube sheet 2, and the other side of the cylinder body 1 opposite to the shell side primary steam inlet pipe 8 is close to the lower tube sheet 3. There is a shell-side condensed water outlet pipe 9, a tube-side solution...

Embodiment 2

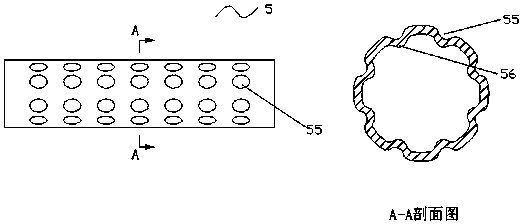

[0031] like figure 1 and image 3 As shown in the figure, the structure of the central circulating tube evaporator is the same as that of Embodiment 1, except that: the outer surface of the boiling tube 5 is provided with 8 micro-concave surfaces 55 along the circumferential direction, and the micro-concave surfaces 55 are spherically arranged on the outer surface of the boiling tube 5. The surfaces are equally spaced along the axial direction, and spherical protrusions 56 are formed on the inner surface of the boiling tube 5 corresponding to the micro-concave surface 55 outside the tube. The ratio of the diameter of the micro-concave surface 55 to the diameter of the boiling tube 5 is 1:10.

Embodiment 3

[0033] like figure 1 and Figure 4 As shown in the figure, the structure of the central circulating tube evaporator is the same as that of the embodiment 1, the difference is that, in order to further improve the convective heat transfer coefficient, the outer surface of the boiling tube 5 is provided with four grooves 51 and four microchannels at intervals along the circumferential direction. The concave surfaces 55 and the four micro-concave surfaces 55 are evenly arranged on the protrusions 54 in the two adjacent grooves 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com