Tube and fixed bed coupled microchannel alkylation reactor and its application

An alkylation reactor and alkylation reaction technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of limiting the quality of alkylated oil products, Problems such as differences in residence time and influence on selectivity, to achieve the effect of improving macroscopic reaction rate and selectivity, precise residence time, and easy control of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

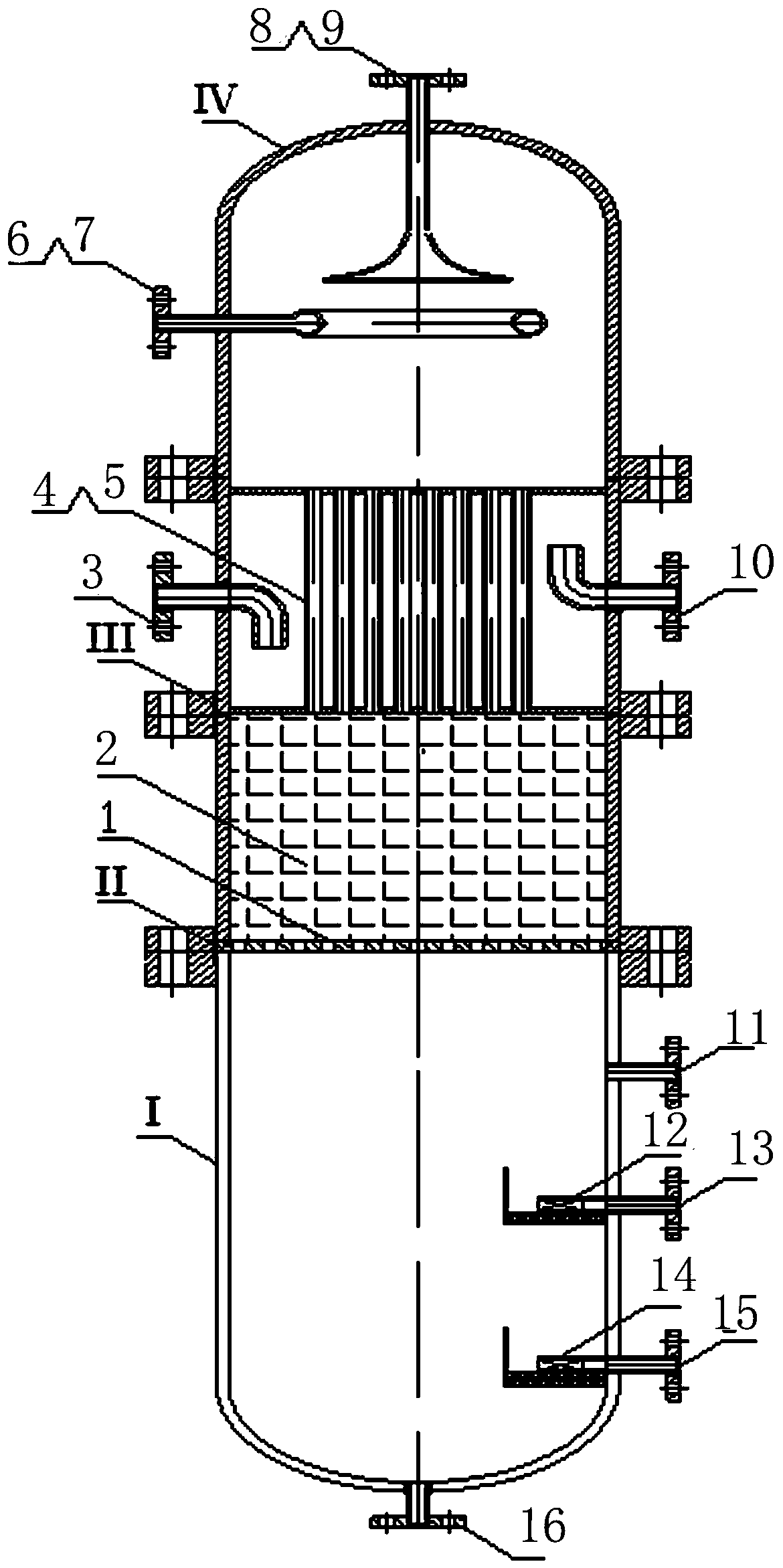

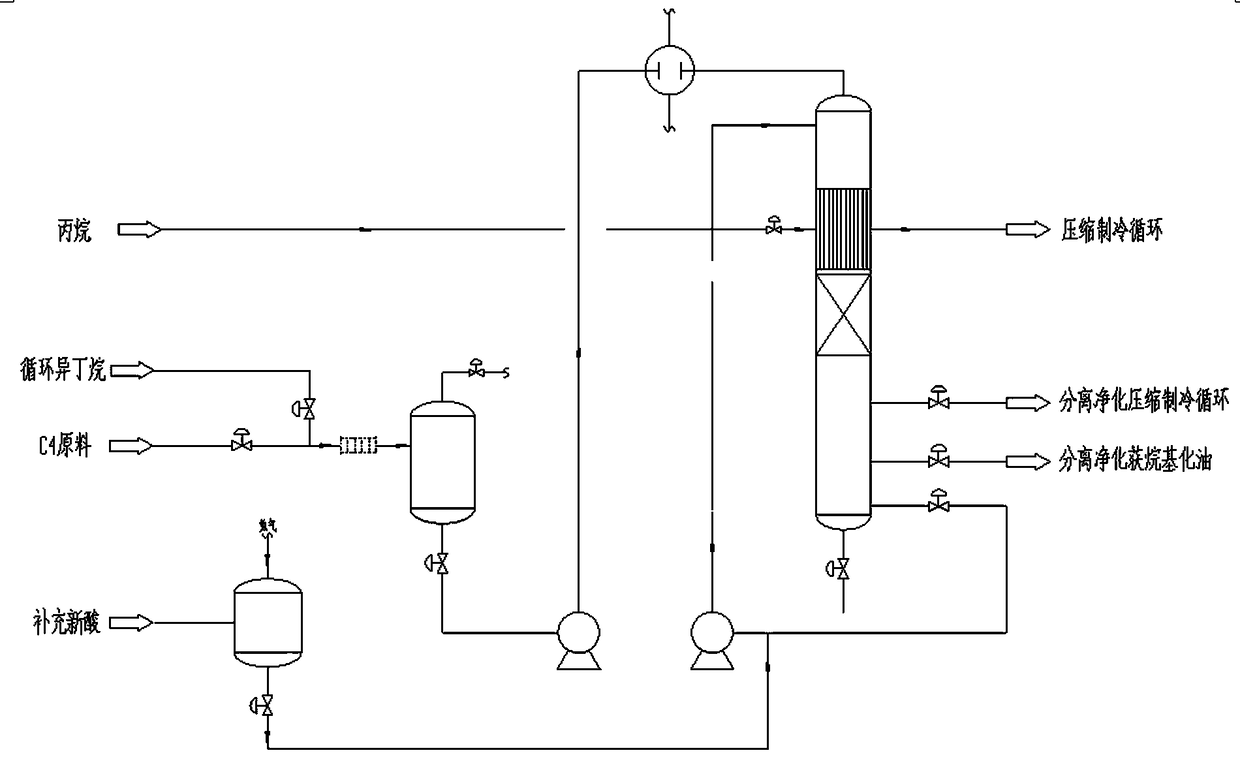

[0048] use as figure 1 The reactor with the structure shown and figure 2 In the shown alkylation reaction process, concentrated sulfuric acid is used as a catalyst and propane is used as a refrigerant to carry out the alkylation reaction.

[0049] The molar ratio of isobutane to olefin is 1~50:1, preferably 3~10:1; the volume ratio of acid to hydrocarbon is 0.2~5:1, preferably 0.5~2:1; the residence time of the reaction materials in the reactor The time is 0~100min, preferably 1~30min. The pressure at the bottom of the reactor is 0~0.1 MPa, preferably 0~0.03 MPa, the pressure drop of the fixed bed layer is 0~0.5 MPa, preferably 0~0.2 MPa, and the pressure drop of the tubular bed layer III is 0~1.0 MPa, preferably It is 0.15~0.5MPa. The reaction temperature is maintained at -7~7°C, preferably -3~3°C.

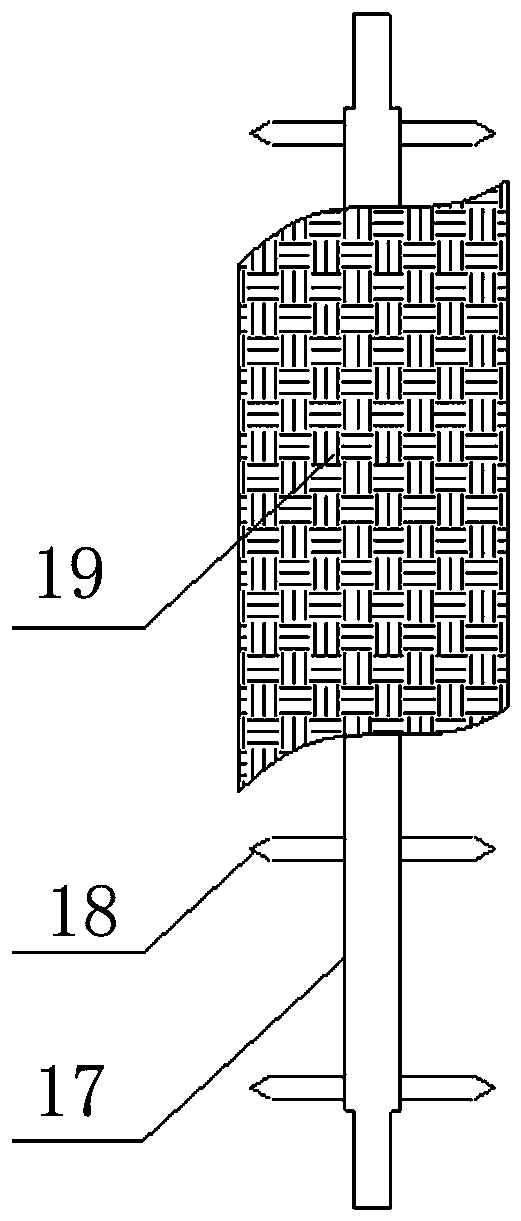

[0050] The structure of the tubular bed layer III is: the diameter of the microchannel tube is 10~30mm, and the equivalent diameter of the tubular microchannel is 5~500μm (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com