Rice husking device

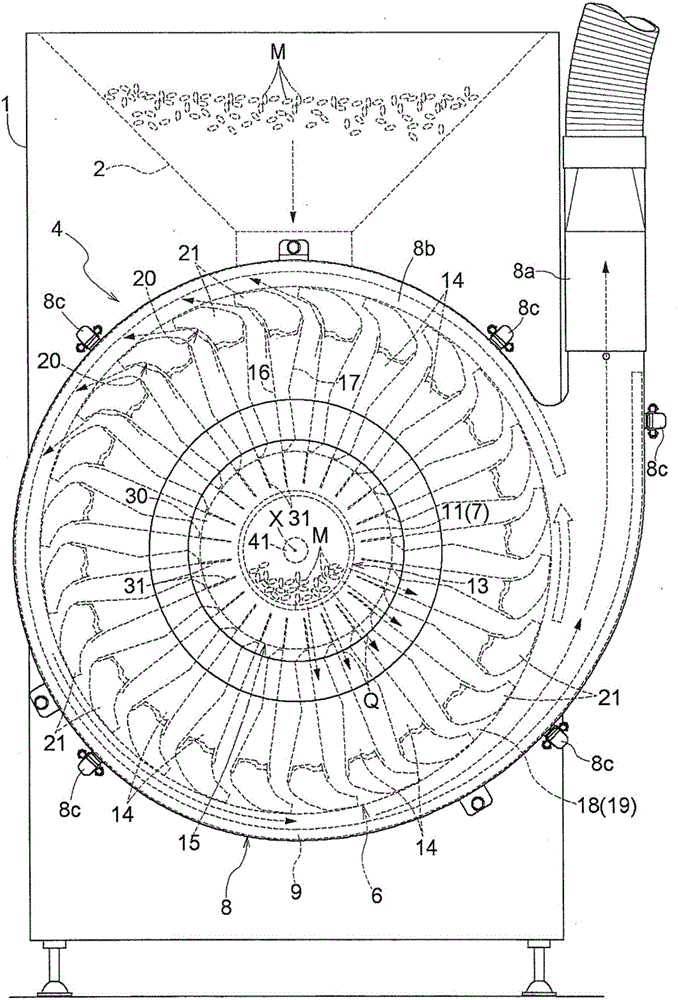

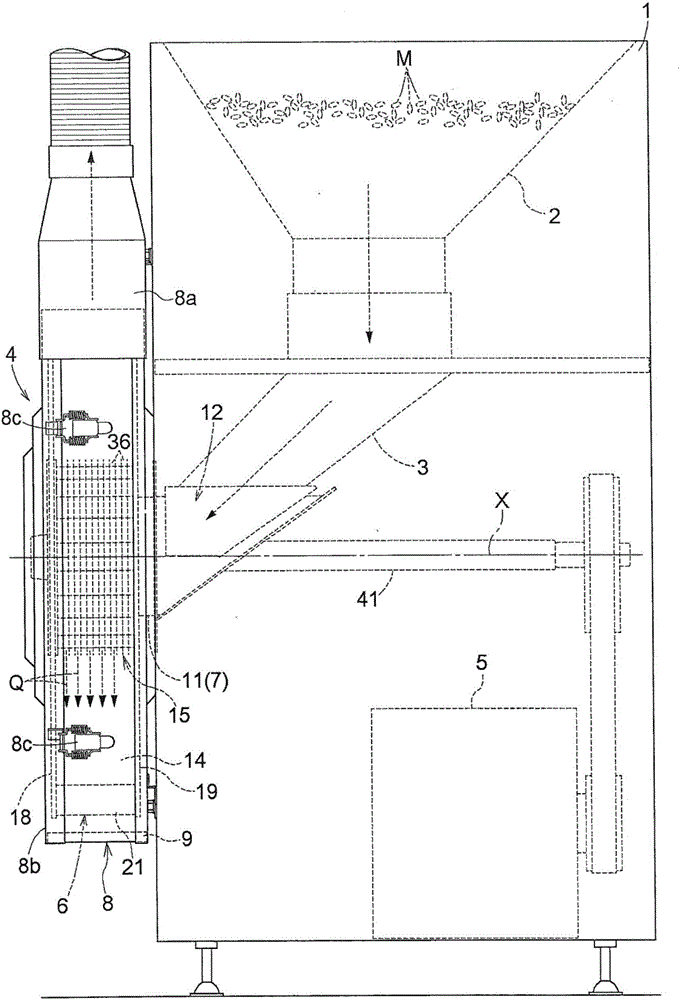

A technology of paddy and rotation direction, which is applied in the directions of grain husking, grain processing, and grain pod removal, etc., which can solve the problems of reduced husking rate, large deviation of throwing direction and throwing speed, and deviation of lining ring speed and angle. Problems such as the state of shelling, to achieve the effect of improving the rate of shelling and good use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

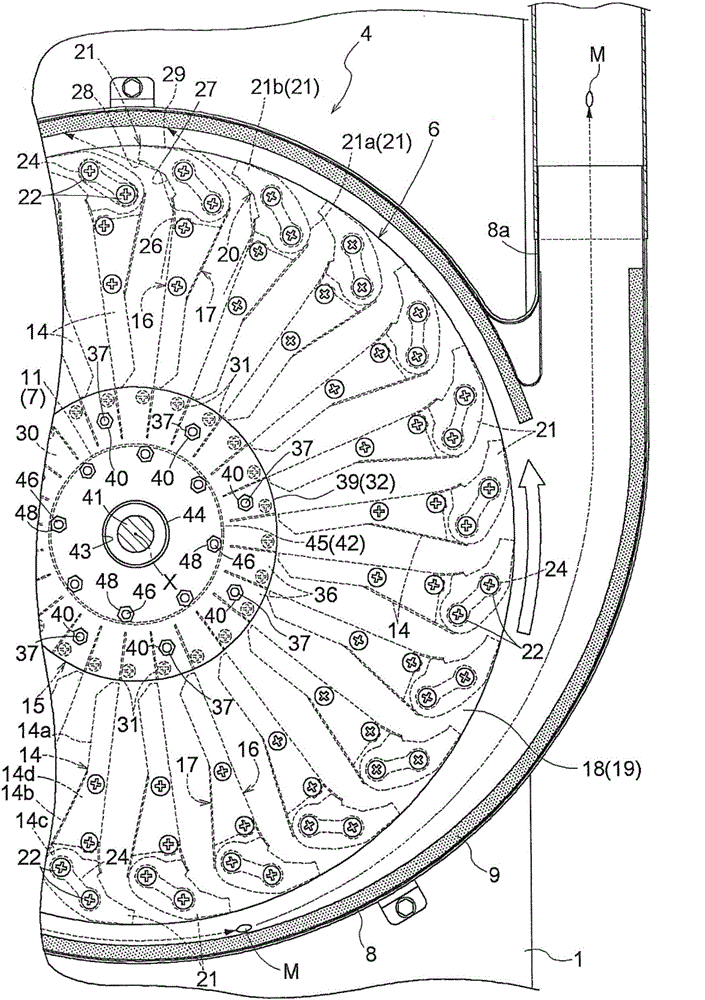

[0111](1) In the above-mentioned embodiment, only the outer guide surface 29 is formed on the radially outer end portion of the rice guide assembly 21 as the inner shelling portion. A radially outer end portion of the shell portion is formed with a protrusion structure that protrudes radially outward and widens toward the rotation axis.

[0112] Such as Figure 15 As shown, at the radially outer end portion of the rice guide assembly 21 as the inner husking part, an outer guide surface 29 set to be substantially parallel to the inner peripheral surface of the outer husking part can also be formed, and form a guide surface from the outside. The most upstream portion in the rotation direction of the surface 29 is a protrusion 51 protruding outward along a direction substantially perpendicular to the outer guide surface 29 , that is, along the radial direction. Such as Figure 16 , Figure 17 As shown, this protrusion 51 is formed in the state which spans the whole area of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com