A fast hot melt glue gun

A hot-melt glue gun and fast technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of low heating efficiency, affecting rapid glue dispensing, poor thermal conductivity of insulating films, etc. Direct heating effect and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

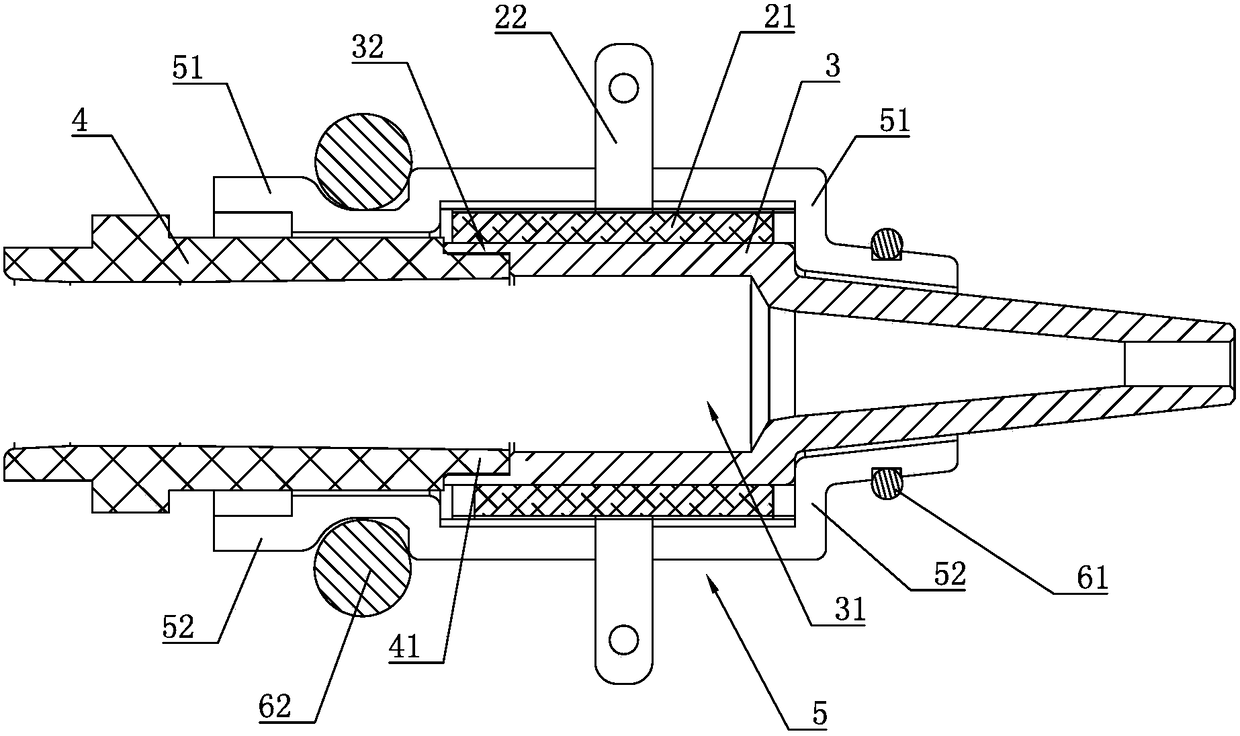

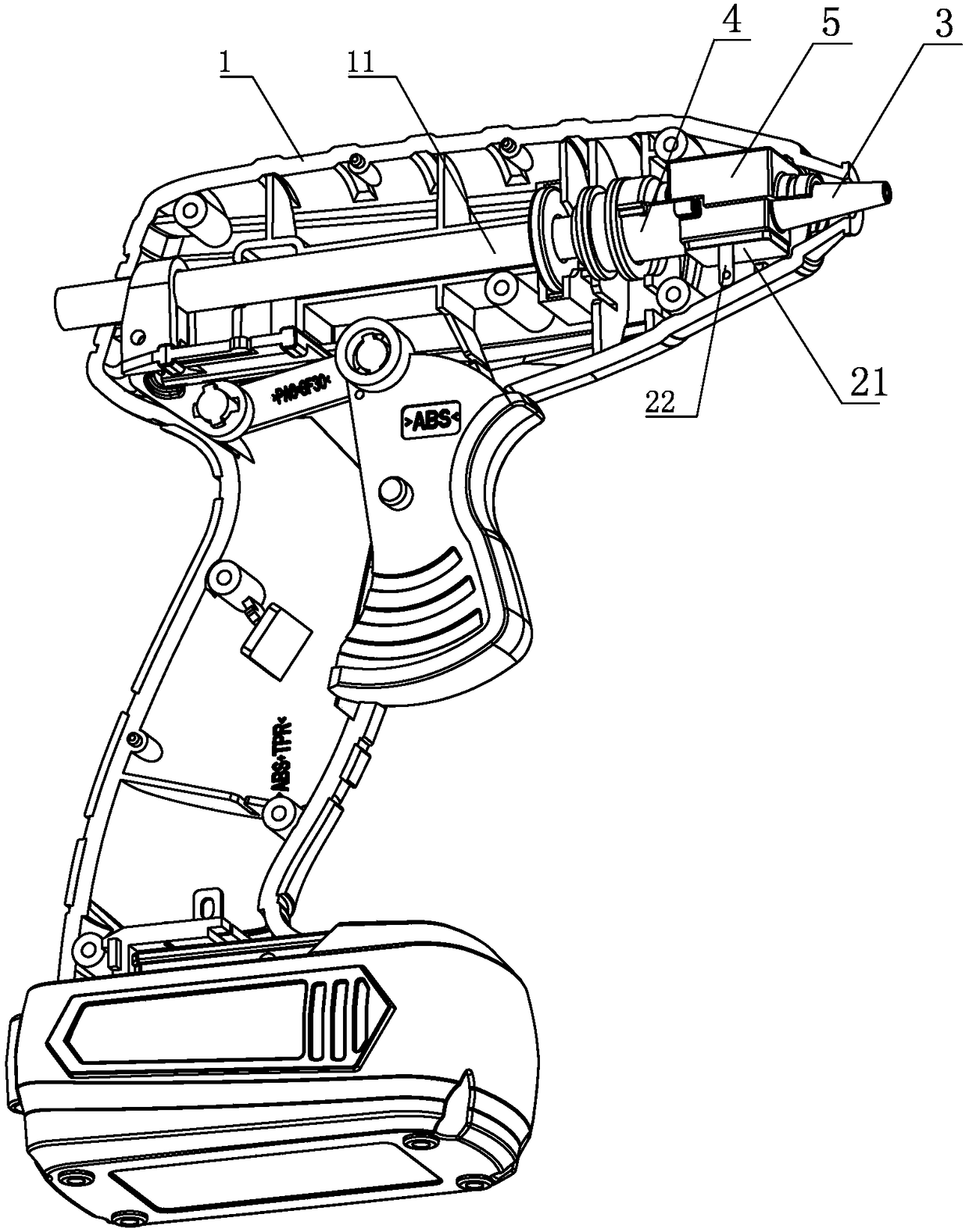

[0018] Embodiment 1: A fast hot-melt glue gun, including a gun body 1, a glue stick 11, a hot-melt device and a power module (not shown in the figure) are arranged in the gun body 1, and the hot-melt device includes a PTC ceramic heating sheet 21, Negative connecting piece 22 and conductive heating head 3, the conductive heating head 3 is provided with a thermal melting cavity 31, the PTC ceramic heating chip 21 is arranged outside the thermal melting cavity 31 and the inner side of the PTC ceramic heating chip 21 is close to the conductive heating head 3 On the top, the PTC ceramic heating piece 21 is electrically connected to the negative input end of the power module through the negative connecting piece 22, the conductive heating head 3 is electrically connected to the positive input end of the power module, and the rear end of the conductive heating head 3 is provided with a leak-proof rubber sleeve 4 , the rear end of the conductive heating head 3 is provided with a conne...

Embodiment 2

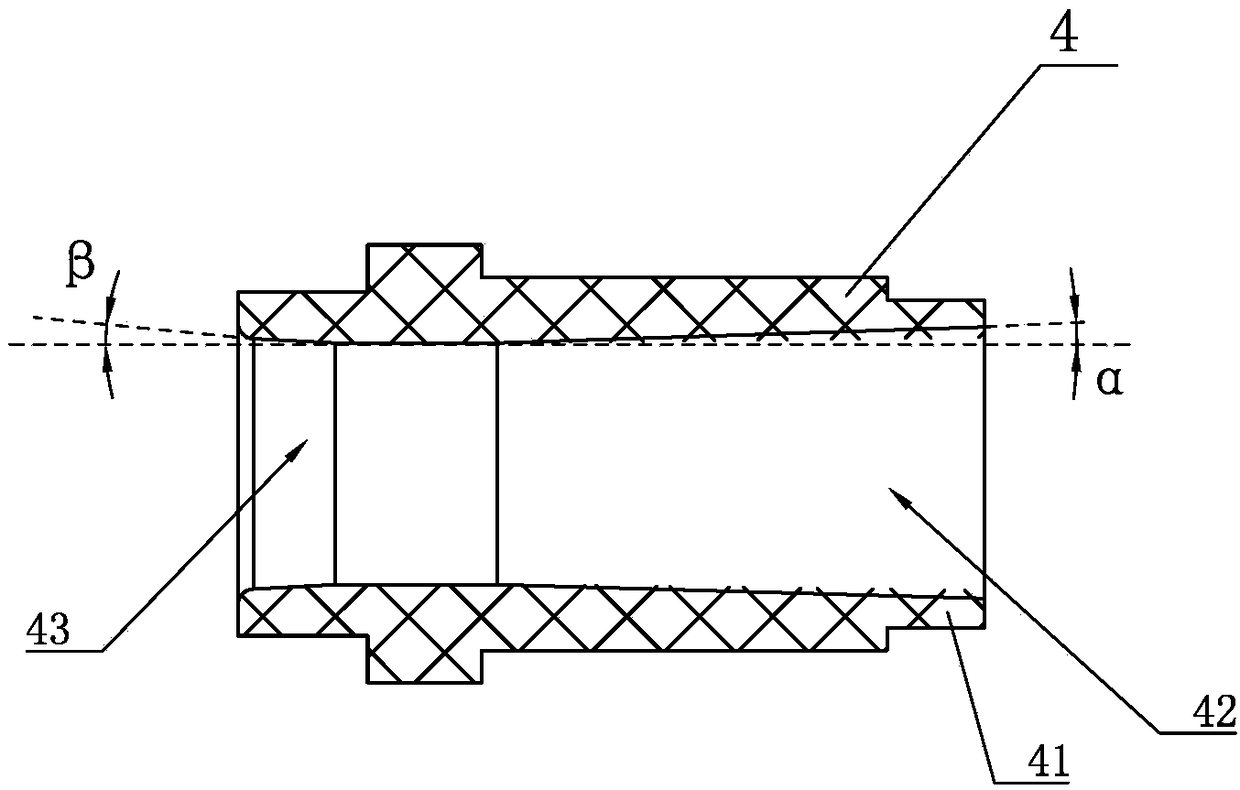

[0019] Embodiment 2: The remaining parts are the same as Embodiment 1, the difference is that a heat-insulating bushing 5 is arranged around the outside of the conductive heating head 3, and the PTC ceramic heating sheet 21 is located between the heat-insulating bushing 5 and the conductive heating head 3 , There are two PTC ceramic heating chips 21, and the two PTC ceramic heating chips 21 are symmetrically arranged on both sides of the conductive heating head 3, and the inclination angle α of the inner surface of the first tapered through hole 42 is 0.8°. Wherein, the heat-insulating bushing 5 is made of high-temperature-resistant and non-conductive material, which can play a role of heat insulation, reduce heat loss, and ensure the heating effect. In this embodiment, the thermal insulation bushing 5 can be made of PA66 (polyamide 66, polyamide 66 or nylon 66) material.

Embodiment 3

[0020] Embodiment 3: the rest is the same as Embodiment 1, the difference is that the heat insulation bushing 5 includes a first heat insulation half shell 51 and a second heat insulation half shell 52 arranged symmetrically, surrounding the first heat insulation half shell A first clip 61 and a second clip 62 are clamped on the outer sides of the shell 51 and the second heat-insulating half-shell 52 , and the inclination angle α of the inner surface of the first tapered through hole 42 is 3°.

[0021] In the first to third embodiments above, if the inclination angle α of the inner surface of the first tapered through hole 42 is unreasonably set, the melted colloid will easily accumulate in the middle of the leak-proof rubber sleeve 4 to form an arch or other shapes, so that Glue stick 11 can not extrude smoothly when using again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com