Coating process for preventing coating from cracking

A coating process and coating technology, used in coatings, devices for coating liquids on surfaces, and surface pretreatment, etc., can solve the problems of easy cracking, inability to industrialize, and exposure of coatings, and achieve enhanced mechanical strength and Insulation performance, coating cracking prevention, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

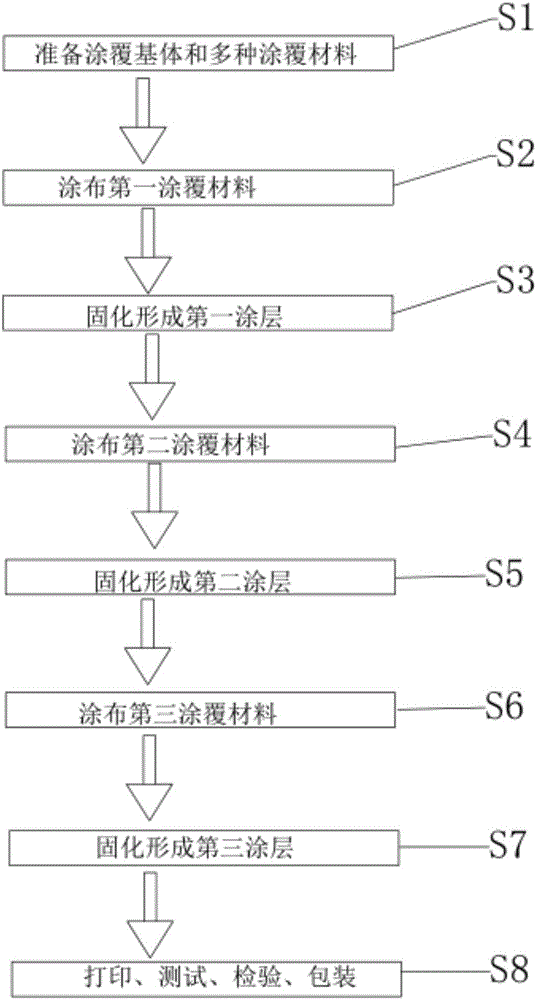

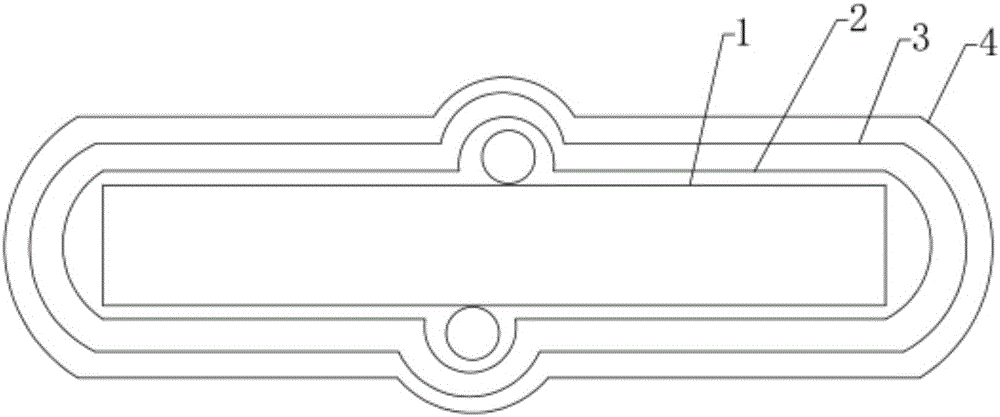

[0025] Please refer to figure 1 and figure 2 , figure 1 It is the coating process flow chart of the present embodiment to prevent cracking of the coating, figure 2 is a schematic cross-sectional view of the coated product of this embodiment. As shown in the figure, step S1 is performed to prepare a substrate 1 and three coating materials. In this embodiment, the substrate is a varistor, and the three coating materials include a first coating material, a second coating material and a third coating material, and the three are powdered epoxy resins of different compositions. Next, step S2 is executed, and the powdery first coating material is coated on the surface of the substrate 1 by a coating machine. Execute step S3, place the semi-finished product after step S2 in an oven, set the temperature of the oven to 150° C., and bake for 120 minutes, so that the first coating material is cured on the surface of the substrate 1 to form the first coating 2 . Continue to execute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com