An internal polishing and cleaning equipment for air-conditioning condensing copper pipes

A technology for cleaning equipment and copper pipes, which is applied in the field of polishing and cleaning equipment for the interior of air-conditioning condensing copper pipes, can solve the problems of no equipment, different inner diameters of copper pipes, and difficulty in cleaning the inner wall, and achieves the effect of ensuring cleaning rate and eliminating dirt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

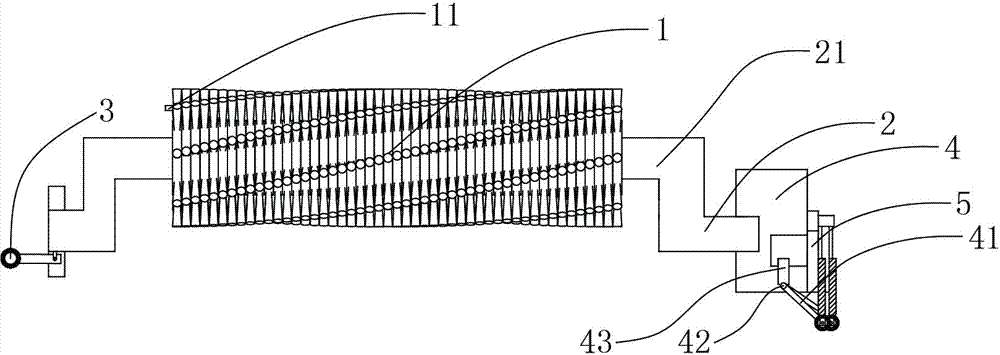

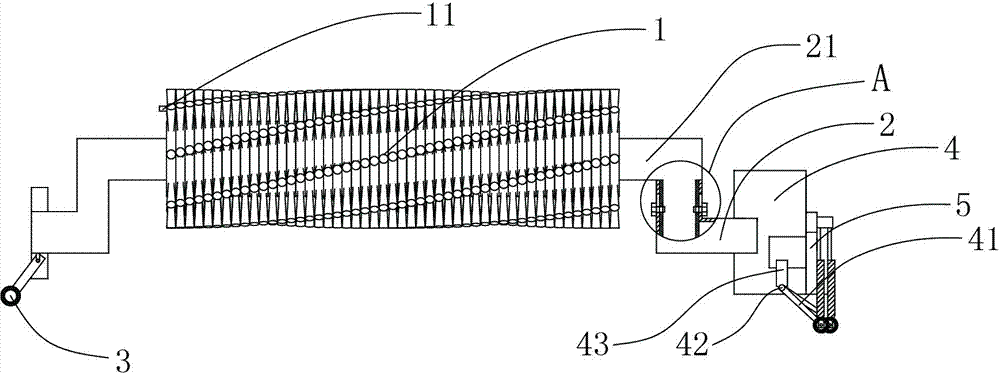

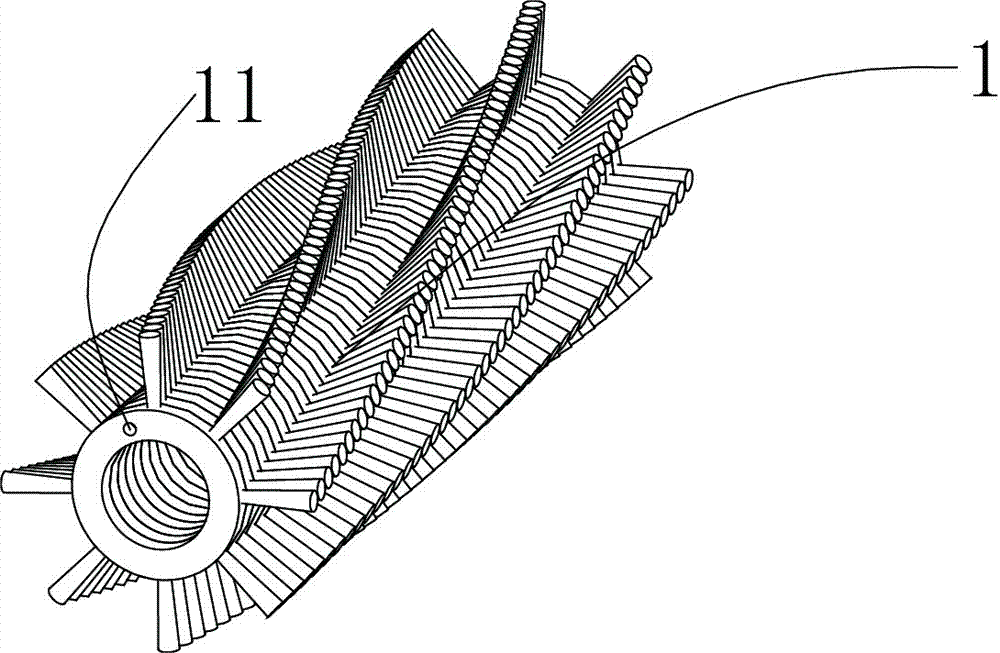

[0021] An internal polishing and cleaning equipment for air-conditioning condensing copper pipes, including a spiral bristle 1, the spiral bristle 1 is fixed on a crank, the crank includes two parts: a rotating shaft part 2 and a telescopic part 21, and the rotating shaft part 2 is A round hole 211 is provided, a waist hole 212 is provided on the telescopic part 21, a driving mechanism is provided at the rear end of the crank, and the driving mechanism includes a motor 4, and a mounting seat is provided on the motor 4 , the mounting seat is provided with a slide block 43 that can slide up and down, and the drive shaft 42 is fixedly arranged on the slide block 43, and the drive shaft 42 drives the roller 61 to rotate through the pulley 41, and the roller 61 Set on the adjustment disc 5, the middle of the adjustment disc 5 is provided with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com