Laminating mechanism

A technology for attaching and profiling components, applied in the direction of lamination device, control lamination, lamination, etc., can solve the problem of time-consuming and labor-intensive, and achieve the effect of improving work quality and good lamination effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

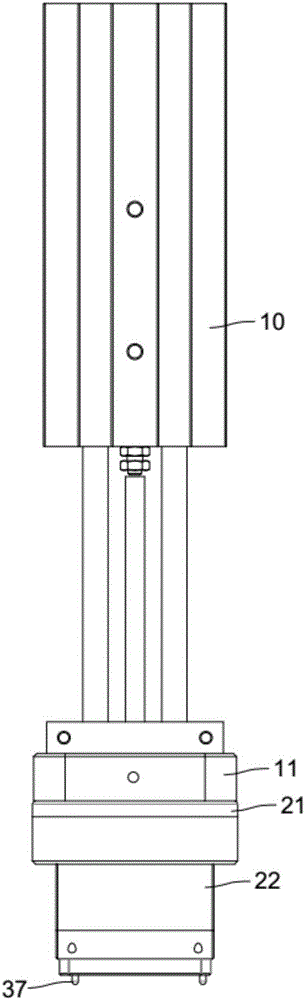

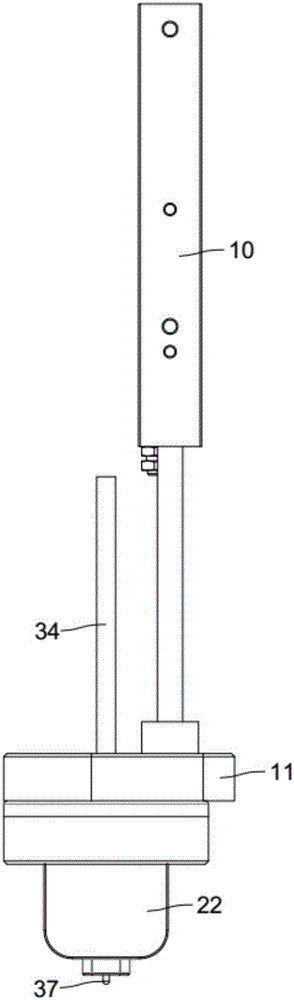

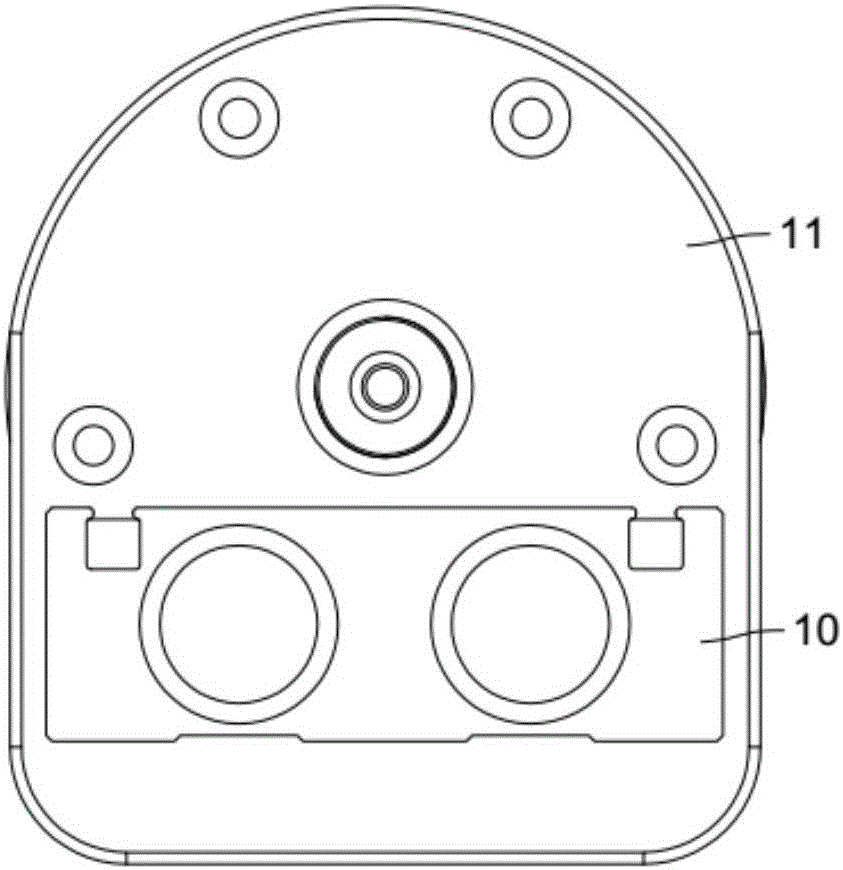

[0025] combine Figure 5 to Figure 7 , an attachment mechanism, including a suction component movably inserted in the profiling component, the bottom end of the suction component protrudes downward from the profiling component, the top of the suction component is in elastic contact with the profiling component, and the profiling component is in contact with the straight line The lifting mechanism 10 is connected; a positioning pin 37 is provided on the bottom surface of the adsorption assembly.

[0026] combine Image 6 , Figure 7 , the profiling assembly includes a profiling head cover 21 fixedly connected with the linear lifting mechanism 10, a profiling head 22 fixedly connected with the profiling head cover, the profiling head offers a T-shaped slot 220, the slot Down through the bottom end face of the contouring head. The adsorption assembly includes an adsorption pressure head 31 and a pressure head cover plate 32 fixed on the top surface of the adsorption pressure h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com