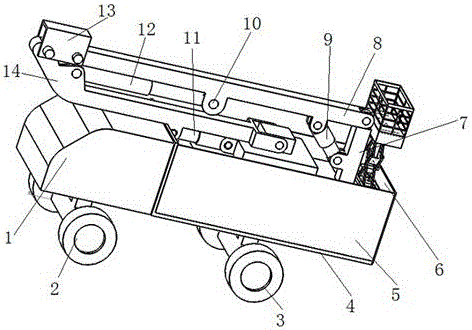

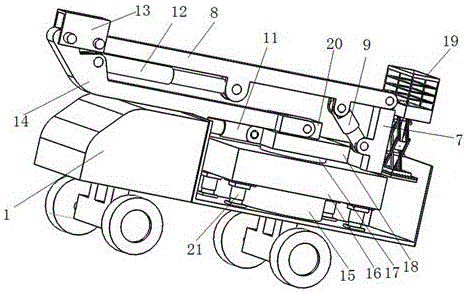

Combined-type emergency power repair vehicle

An electric emergency repair vehicle and combined technology, which is applied in the direction of motor vehicles, goods transport vehicles, and vehicles used for freight transportation, can solve the problems of affecting the process and speed of electric power operations, untimely adjustment, and inconvenient rotation, etc., so as to reduce adjustments Time and adjust the difficulty, prevent safety hazards, increase the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

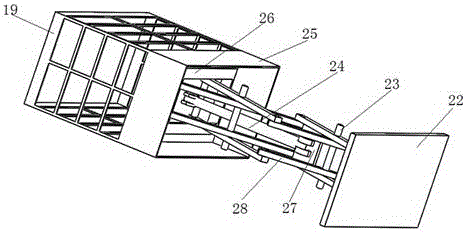

[0021] In this embodiment, on the basis of Embodiment 1, further, the bottom surface of the workbench bottom plate 30 is provided with a vertical ladder upper plate 26 near the edges of both sides; the lower side of the workbench bottom plate 30 is provided with a supporting hydraulic pressure Shaft 24; the bottom end of the supporting hydraulic shaft 24 is connected with a hydraulic rod support plate 27; the lower side of the upper plate 26 of the vertical ladder is provided with a group of support bars 28; The position of supporting shaft 23 is provided with; The bottom of described lower supporting bar 28 is connected with vertical ladder bottom plate 29; The bottom surface of described vertical ladder bottom plate 29 is connected with workbench base plate 22; The two sides are respectively connected with the inner side of the chassis 16 and the rear plate 6 .

[0022] When the present invention is implemented, the chassis rotating shaft 15 is installed below the chassis 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com