Automobile doorsill

A technology for door sills and automobiles, which is applied in the directions of vehicle components, superstructure, and sub-assembly of superstructures, etc., can solve problems such as changing the installation method of automobile sills, and achieve the effect of solving difficult installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

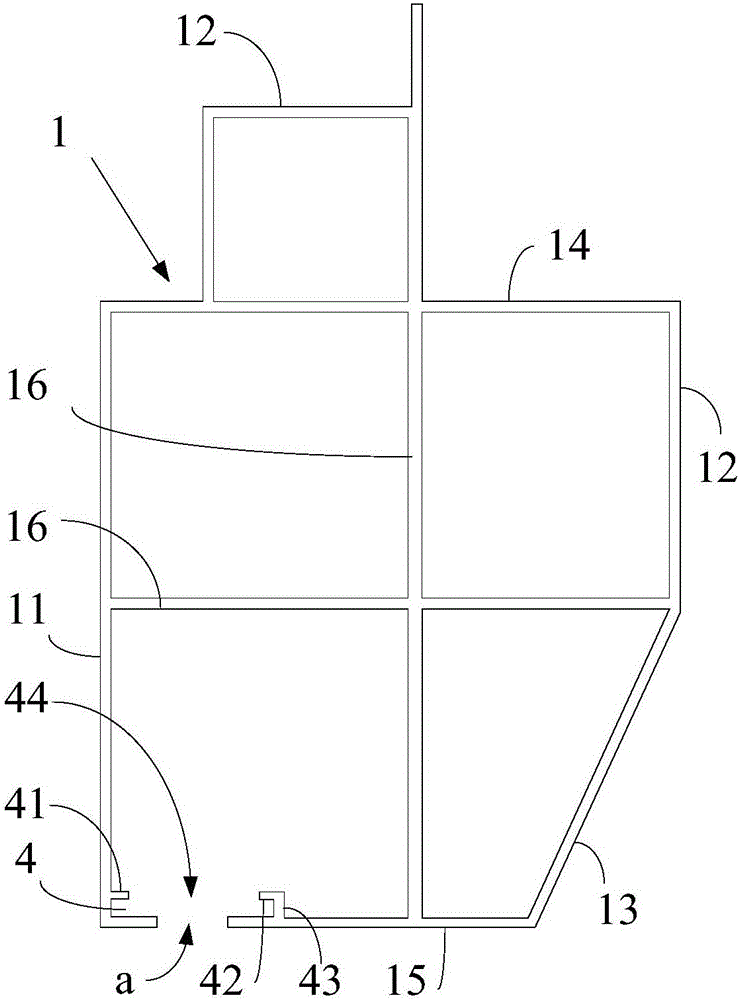

[0025] Embodiments of the present invention provide a car door sill, such as figure 1 As shown, the vehicle threshold includes a threshold beam 1, and the threshold beam 1 is fixedly installed on the vehicle body (not shown). In this embodiment, the specific structure of the automobile threshold is described by taking the vehicle threshold applicable to electric vehicles as an example. It is easy to understand that in other embodiments, the automobile threshold can also be applicable to hybrid vehicles and internal combustion engine vehicles, etc., so , the present invention does not limit the specific installation position of the automobile door sill in the automobile.

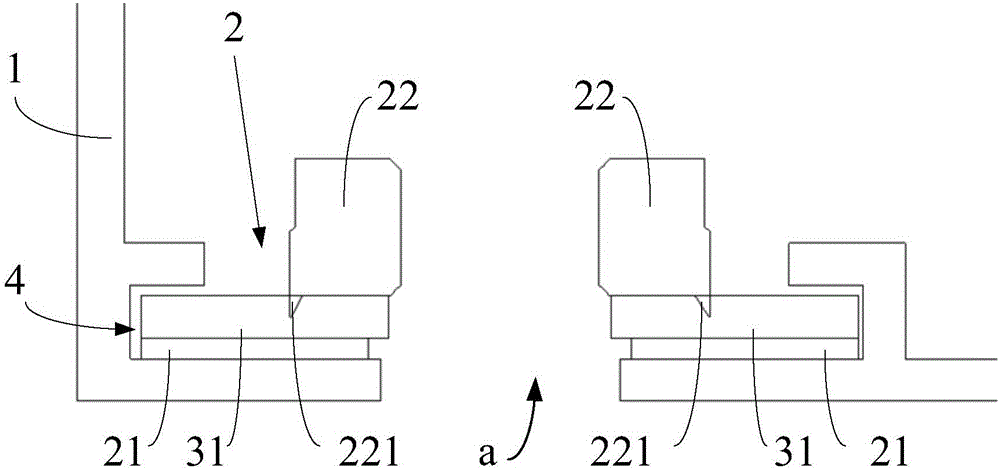

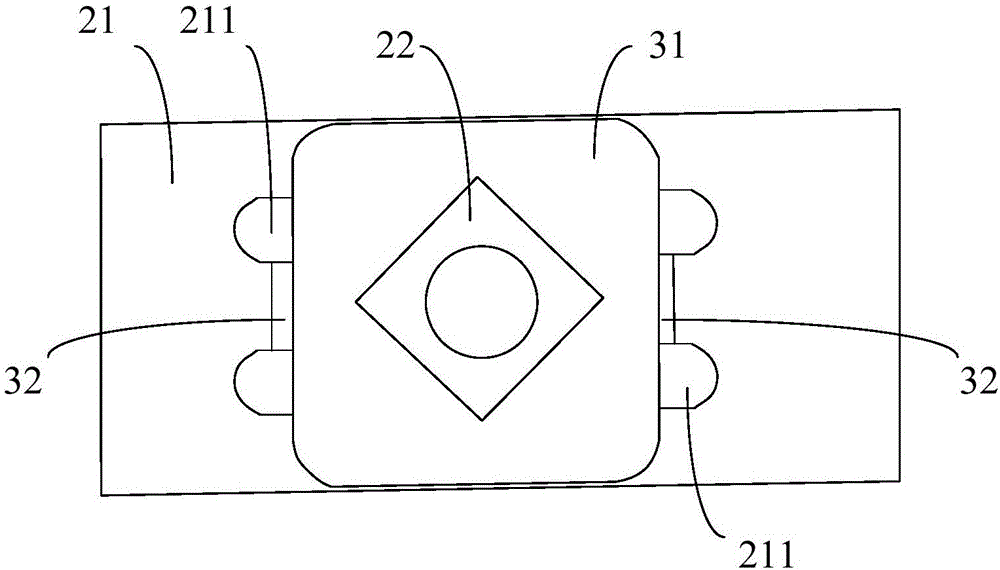

[0026] figure 2 is a partial cross-sectional view of the car door sill, combined with figure 2 , the car door sill also includes a mounting assembly 2, the mounting assembly 2 is arranged in the door sill beam 1, the mounting assembly 2 includes a support plate 21 and a plurality of mounting nuts 22, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com